Synthetic technology of slump-retaining polycarboxylic type water reducer

A technology of polycarboxylic acid series and synthesis process, which is applied in the field of synthesis process of slump-retaining polycarboxylate-based water reducer, which can solve the problems of prolonged concrete setting time, weak slump-preservation ability, and influence on construction progress, etc., and achieves excellent performance. Good workability, good slump stability, and optimized molecular structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

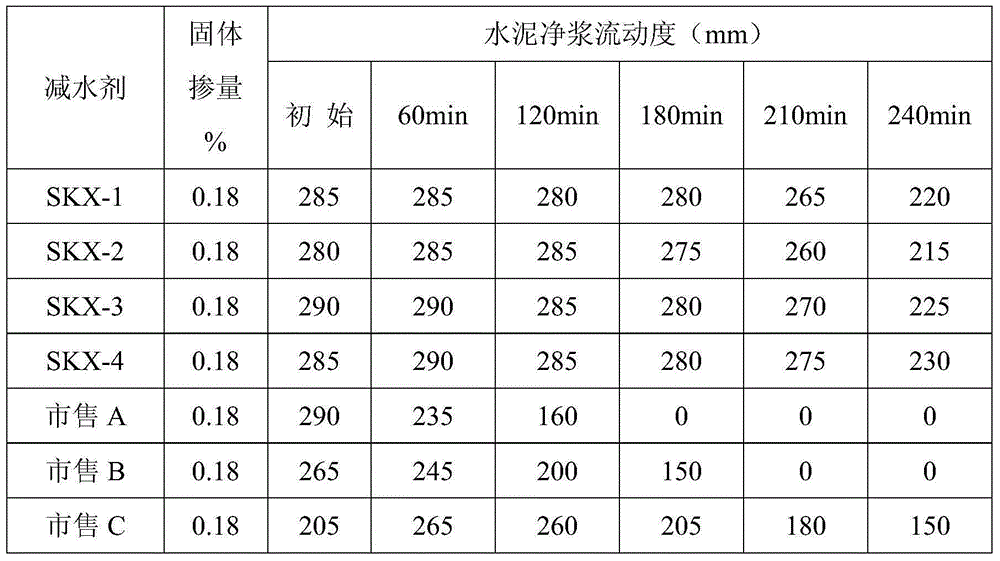

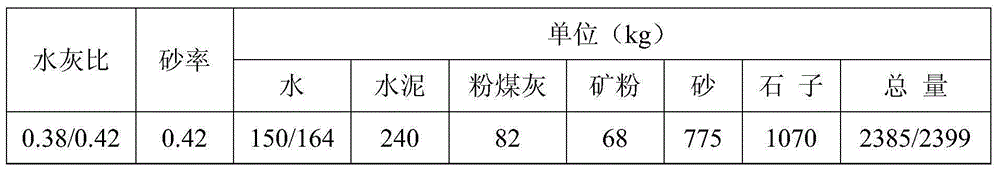

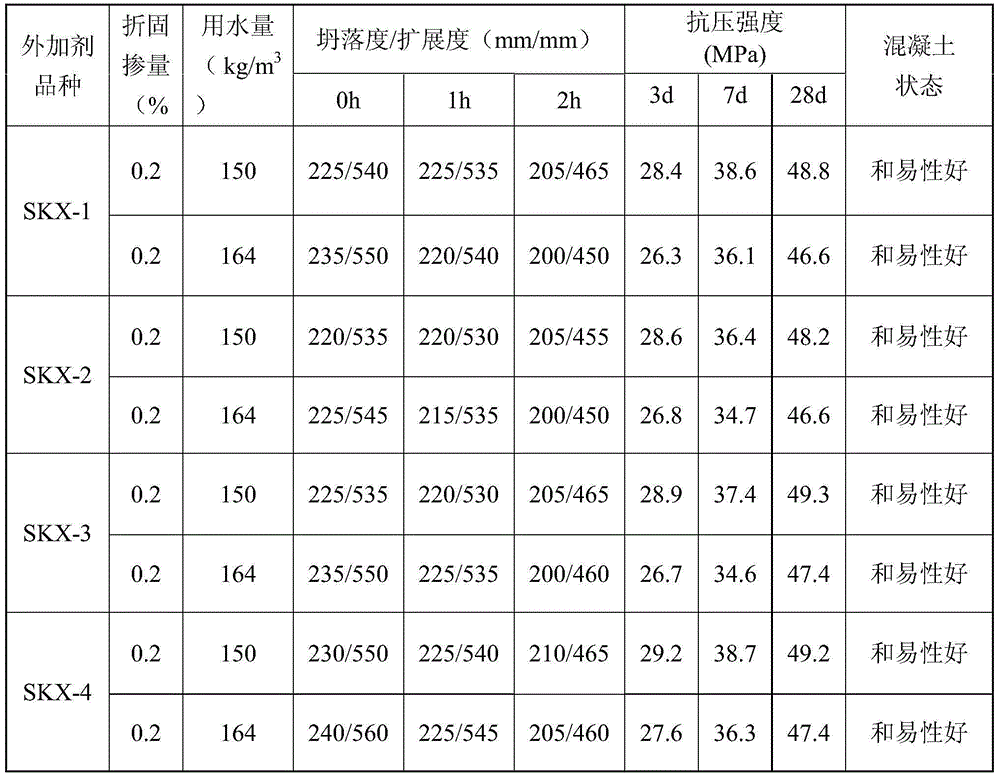

Examples

Embodiment 1

[0029]Add 250 g of deionized water into a 2000 mL four-neck flask, preheat to 30°C, add 430 g of prenol polyoxyethylene ether macromonomer with a molecular weight of 3900 and stir to dissolve. After the macromonomer is dissolved, add 4.77 g of hydrogen peroxide and stir evenly, and add A separately at 30°C with a peristaltic pump. 1 Solution (an aqueous solution consisting of 17.2 grams of acrylic acid, 21.5 grams of β-carboxyethyl acrylate and 25.8 grams of deionized water) was added dropwise for 2.5 hours, and solution B (8.6 grams of 3-allyloxy-2-hydroxypropanesulfonic acid Sodium and the aqueous solution that 77.4 grams deionized water forms) drop time 2.5h and C 1 Solution (an aqueous solution consisting of 1.19 grams of vitamin C, 2.39 grams of 3-mercaptopropionic acid, and 139.62 grams of deionized water) was added dropwise for 2.5 hours.

[0030] A 1 Liquid, B liquid and C 1 After the liquid drops, add 4.26 grams of hydrogen peroxide and stir evenly, and immediately...

Embodiment 2

[0033] Add 250 g of deionized water into a 2000 mL four-neck flask, preheat to 30°C, add 430 g of prenol polyoxyethylene ether macromonomer with a molecular weight of 3900 and stir to dissolve. After the macromonomer is dissolved, add 7.29 g of hydrogen peroxide and stir evenly, and add A separately at 30°C with a peristaltic pump. 1 Solution (an aqueous solution consisting of 21.5 grams of acrylic acid, 23.65 grams of β-carboxyethyl acrylate and 30.1 grams of deionized water) was added dropwise for 2.5 hours, solution B (10.75 grams of 3-allyloxy-2-hydroxypropanesulfonic acid Sodium and 96.75 grams of deionized water aqueous solution) drop time 2.5h and C 1 Solution (an aqueous solution consisting of 1.21 grams of vitamin C, 2.43 grams of 3-mercaptopropionic acid and 141.96 grams of deionized water) was added dropwise for 2.5 hours.

[0034] A 1 Liquid, B liquid and C 1 After the liquid drops, add 4.26 grams of hydrogen peroxide and stir evenly, and immediately dropwise ad...

Embodiment 3

[0037] Add 250 g of deionized water into a 2000 mL four-neck flask, preheat to 30°C, add 430 g of prenol polyoxyethylene ether macromonomer with a molecular weight of 3900 and stir to dissolve. After the macromonomer is dissolved, add 6.07 g of hydrogen peroxide and stir evenly, and add A separately at 30°C with a peristaltic pump. 1 Solution (an aqueous solution consisting of 25.8 grams of acrylic acid, 17.2 grams of β-carboxyethyl acrylate and 28.7 grams of deionized water) was added dropwise for 2.5 hours, and solution B (12.9 grams of 3-allyloxy-2-hydroxypropanesulfonic acid Sodium and the aqueous solution that 116.1 gram deionized waters form) drop time 2.5h and C 1 Solution (an aqueous solution composed of 1.22 grams of vitamin C, 2.43 grams of 3-mercaptopropionic acid and 142.35 grams of deionized water) was added dropwise for 2.5 hours.

[0038] A 1 Liquid, B liquid and C 1 After the liquid drops, add 4.35 grams of hydrogen peroxide and stir evenly, and immediately ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com