Cellulose acetate/nano cellulose blended ultrafiltration film

A technology of nanocellulose and cellulose acetate, applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of low anti-pollution, low flux of ultrafiltration membrane, etc. High throughput and improved hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

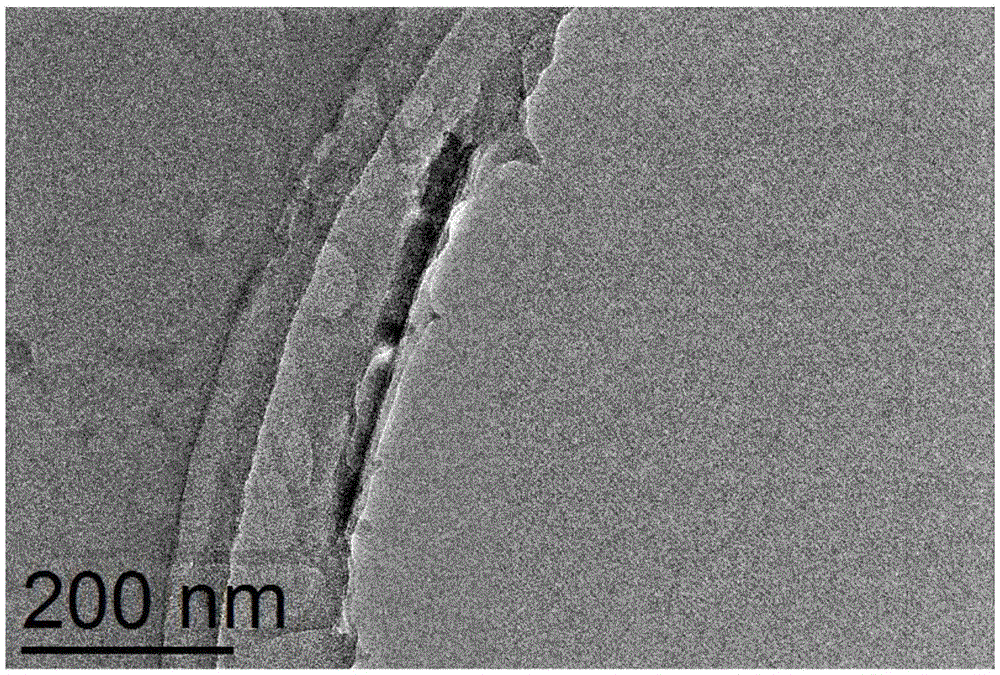

Image

Examples

Embodiment

[0016] The cellulose acetate content is 97wt% of the polymer content, and the nanocellulose content is 3wt% of the polymer content. Add nanocellulose to 32.8wt% N,N-dimethylformamide, and use ultrasound to disperse nanocellulose fully and uniformly in it at room temperature. After the dispersion is completed, add it to the beaker, and then add the cellulose acetate , 2wt% polyethylene glycol, and 49.2wt% acetone were stirred in a water bath at 35°C until fully uniform. Then, the obtained casting solution is left to stand, and the bubbles remaining in the casting solution are removed by ultrasonic defoaming. Finally, pour the film-casting solution on a clean glass plate, scrape it with a scraper to form a film, and immerse it in an ice-water bath. After the film is formed and separated from the glass plate, rinse it with deionized water to obtain cellulose acetate / nanocellulose Blended ultrafiltration membranes. The tensile strength of the membrane was measured, and the resul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com