Low-smoke halogen-free coal mine electric cable material and preparation method thereof

A technology of cable materials and coal mines, which is applied in the field of low-smoke and halogen-free coal mine cable materials and its preparation, can solve the problems of cables without environmental protection and safety, no elasticity and flexibility, secondary hazards to the environment and life, etc., and achieve good resistance Combustibility, low smoke generation, and improved molecular structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

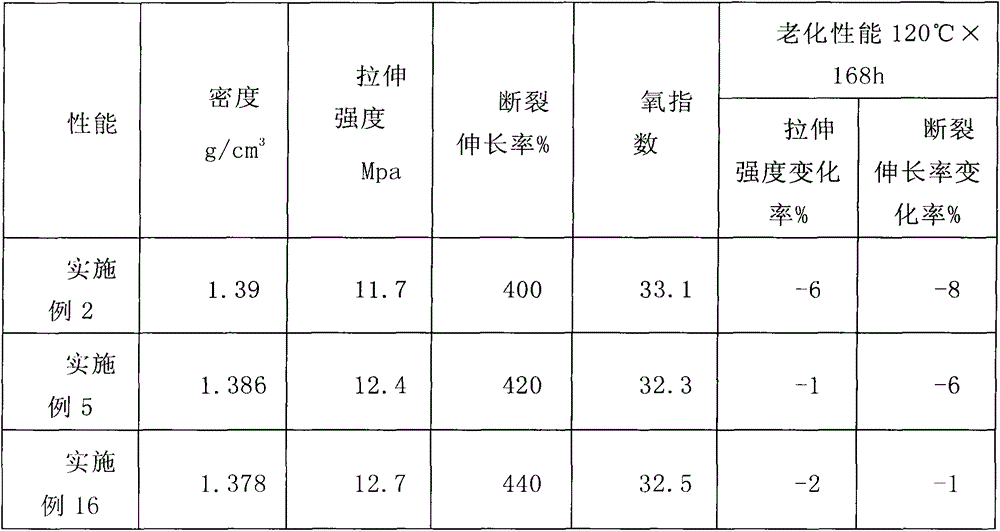

Examples

Embodiment 1

[0066] This embodiment provides a cable material for low-smoke and halogen-free coal mines. The raw material formula of the cable material includes:

[0067] EPDM rubber,

[0068] Ethylene-vinyl acetate rubber,

[0069] flame retardant,

[0070] Reinforcing agent,

[0071] Anti-hydrolysis agent,

[0072] peroxide crosslinker.

[0073] This embodiment also provides a method for preparing a cable material for low-smoke and halogen-free coal mines, which includes the following steps:

[0074] (1) Put the EPDM rubber into the rubber mixing equipment for mastication, and its temperature is controlled at 140°C.

[0075] (2) After blending EPDM rubber and ethylene-vinyl acetate rubber according to the formula ratio for 10 minutes, add flame retardant, reinforcing agent and anti-hydrolysis agent; the temperature is controlled at 140°C.

[0076](3) After cooling to 80-100°C, add a peroxide cross-linking agent and react for a period of time to obtain a low-smoke and halogen-free c...

Embodiment 2

[0082] This embodiment provides a cable material for low-smoke and halogen-free coal mines. The raw material formula of the cable material includes:

[0083] EPDM rubber,

[0084] Ethylene-vinyl acetate rubber,

[0085] Phosphorus nitrogen flame retardants,

[0086] Reinforcing agent carbon black,

[0087] Anti-hydrolysis agent polycarbodiimide SPKC8550-I,

[0088] Peroxide crosslinking agent bis-tert-butylperoxide dicumylbenzene F-40.

[0089] The third monomer of the EPDM rubber in the cable material is ENB type ethylene norbornene, and the ethylene content in the EPDM rubber is 50wt%. The content of vinyl acetate in the ethylene-vinyl acetate rubber in the cable material is 70wt%.

[0090] This embodiment also provides a method for preparing a cable material for low-smoke and halogen-free coal mines, which includes the following steps:

[0091] (1) Put the EPDM rubber into the rubber mixing equipment for mastication, and its temperature is controlled at 135°C.

[009...

Embodiment 3

[0097] This embodiment provides a cable material for low-smoke and halogen-free coal mines. The raw material formula of the cable material includes:

[0098] EPDM rubber,

[0099] Ethylene-vinyl acetate rubber,

[0100] Flame retardant aluminum hydroxide,

[0101] Reinforcing agent magnesium carbonate,

[0102] Anti-hydrolysis agent polycarbodiimide SPKC8550-III,

[0103] Peroxide crosslinking agent bis-tert-butyl peroxide dicumyl peroxide F40P-SP2.

[0104] The ethylene content in the EPDM rubber in the cable material is 60wt%. The vinyl acetate content in the ethylene-vinyl acetate rubber in the cable material is 80 wt%.

[0105] This embodiment also provides a method for preparing a cable material for low-smoke and halogen-free coal mines, which includes the following steps:

[0106] (1) Put the EPDM rubber into the rubber mixing equipment for mastication, and its temperature is controlled at 155°C.

[0107] (2) After blending EPDM rubber and ethylene-vinyl acetate r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com