Seawater-based fracturing fluid and preparation method thereof

A fracturing fluid and seawater technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of insufficient viscosity increasing performance, inability to meet continuous mixing, poor salt resistance and shear resistance, etc. Good shear thinning, preventing seawater pollution, improving salt resistance and shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

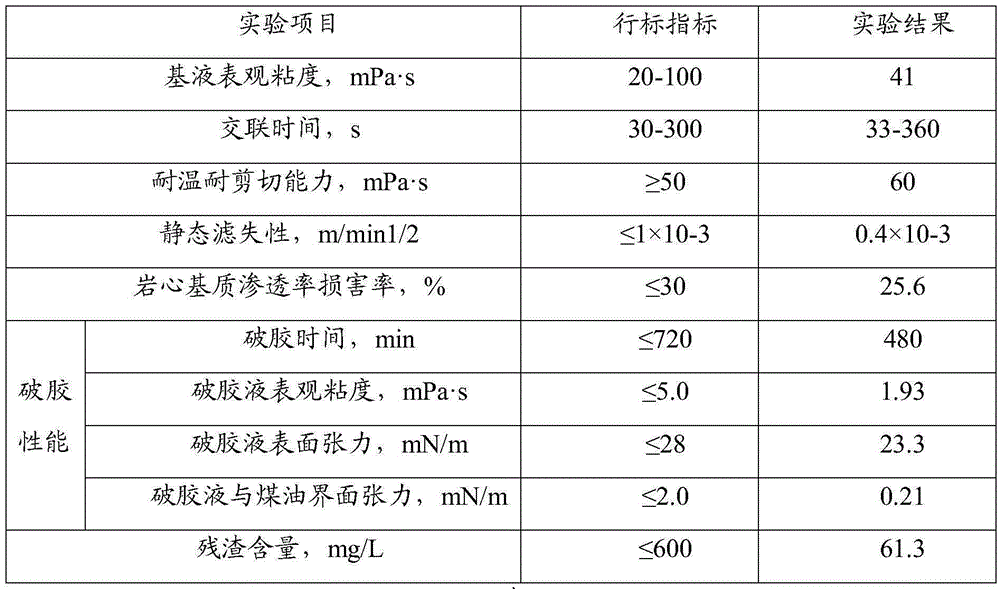

Examples

Embodiment 1

[0035] In this embodiment, a seawater-based fracturing fluid is provided, and the components included in 100 parts of the fracturing fluid and the weight ratio of the components are:

[0036] 0.3-0.8 part of thickener, 0.1-0.6 part of cross-linking agent, 0.05-0.1 part of oxygen scavenger, 0.02-0.05 part of viscosifying aid and 0.05-0.2 part of gel breaker, and all or part of the rest is sea water;

[0037] The thickener is specifically modified polyacrylamide; wherein, the modified polyacrylamide is formed by copolymerization of acrylamide, hydrophobically modified monomer and sulfonate; the hydrophobically modified monomer is dodecane Haloalkane; the sulfonate is 2-acrylamido-2-methylpropanesulfonic acid; wherein, the fracturing fluid has the hydrophobicity of the hydrophobic group through the hydrophobic association of the hydrophobic modification monomer function, to obtain good viscosity-increasing property and improve viscosity-increasing ability; through the copolymeriz...

Embodiment 2

[0065] In this embodiment, a preparation method of seawater-based fracturing fluid is provided, including:

[0066] Proportion by weight:

[0067] Weigh 98.3-99.3 parts of seawater into the mixer;

[0068] Add 0.3-0.8 parts of thickener into the mixer and stir;

[0069] Add 0.05-0.1 part of oxygen scavenger, 0.02-0.05 part of tackifier, 0.3-0.5 part of drainage aid, 0.1-0.3 part of retarder, 0.05-0.2 part of gel breaker and 0.1 part of - 0.6 parts of cross-linking agent, and stirred until the liquid level in the mixer rises slightly to obtain the seawater-based fracturing fluid.

[0070] Specifically, you can use a graduated cylinder to weigh 98.4-99.3 parts of filtered seawater and add it to the mixer, adjust the voltage of the mixer to 50V-55V, then add 0.3-0.8 parts of thickener, set the mixer to stir at high speed for 3 minutes ;

[0071] Then add 0.05-0.1 part of oxygen scavenger, 0.02-0.05 part of tackifier, 0.3-0.5 part of drainage aid, and 0.1-0.3 part of retardant...

example

[0075] 1. The specific ratio of seawater-based fracturing fluid in this example is:

[0076] The base fluid is based on 100 parts of the total solution mass of the prepared seawater-based fracturing fluid, wherein: the filtered seawater accounts for 99.3 parts of the total solution mass, the thickener accounts for 0.3 parts of the total solution mass, and the oxygen scavenger accounts for the total solution mass. 0.05 parts by mass, 0.02 parts of the total solution mass by the tackifier, 0.3 parts by the total solution mass by the drainage aid, and 0.1 part by the total solution mass by the retarder;

[0077] The gel breaker is based on the 0.05% mass fraction of the total solution of the base liquid, and the gel breaker is 0.05 parts.

[0078] The cross-linking agent is based on 0.1% mass fraction of the total solution of the prepared seawater-based fracturing fluid, and the cross-linking agent is 0.1 part.

[0079] The specific preparation method of the above-mentioned seaw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com