Pre-fabricated rubber running track and manufacturing process thereof

A prefabricated, rubber technology, applied in the direction of roads, roads, flat products, etc., can solve the problems of uneven vulcanization degree, poor weather aging performance of products, easy surface cracks, etc., to achieve uniform thickness of specifications, improve weather aging and the effect of ozone resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

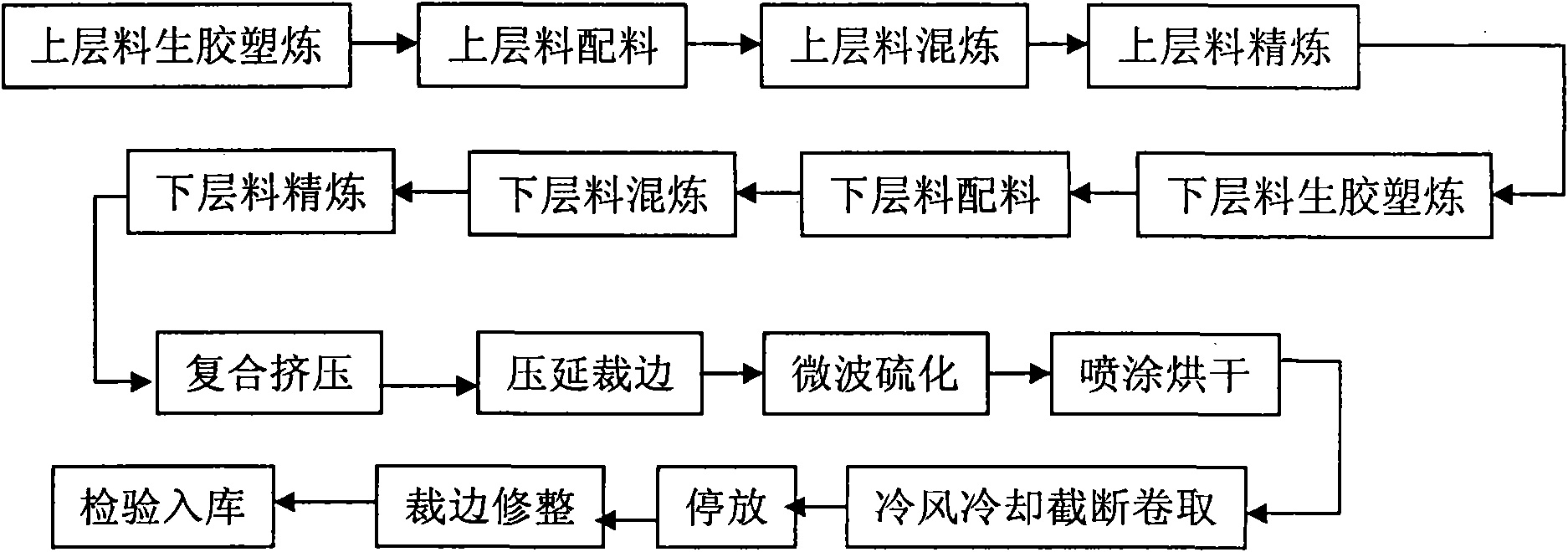

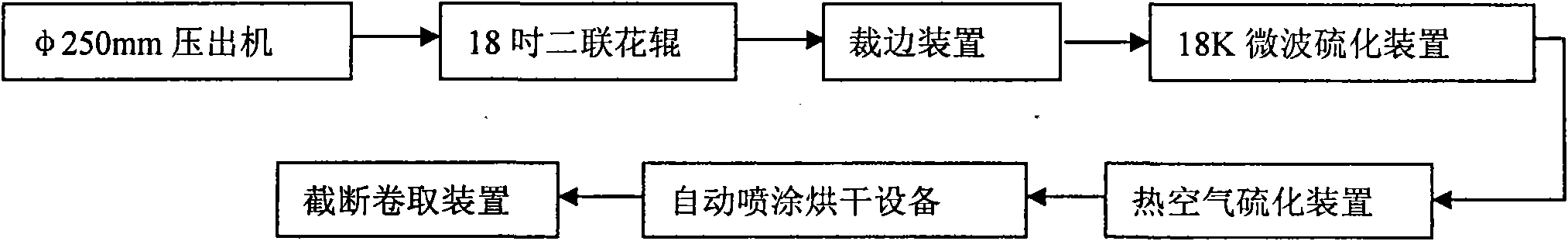

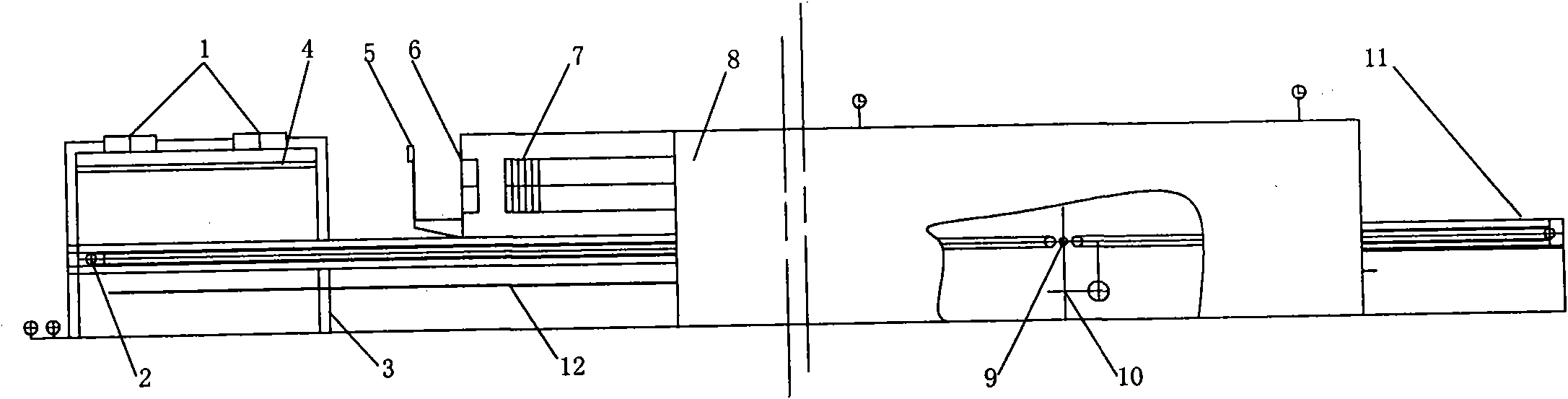

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the drawings and embodiments.

[0040] There are three types of rubber components in the upper material: natural rubber, neoprene rubber and ethylene propylene rubber. There are three types of rubber components in the lower material, which are natural rubber, styrene butadiene rubber and isoprene rubber. There are two types of antioxidant components in the upper material, namely 2246 antioxidant and MB antioxidant. The ultraviolet absorber in the upper layer material is UV-9 ultraviolet absorber. There are three types of vulcanization accelerator components in the upper material, namely CZ accelerator, BZ accelerator and NA-2 accelerator. There are three types of vulcanization accelerator components in the lower layer material, namely M accelerator, DM accelerator and TS accelerator.

[0041] Examples of formulas for prefabricated rubber track top materials:

[0042] The composition of the upper laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com