Production technology of double-surface clipping V-shaped band

A production process and double-sided technology, applied in belts, applications, household appliances, etc., can solve the problems of large bending stress, low lateral stiffness, high dynamic heat generation, etc., to improve hardness and impact strength, improve dynamic mechanical properties, The effect of increasing lateral stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

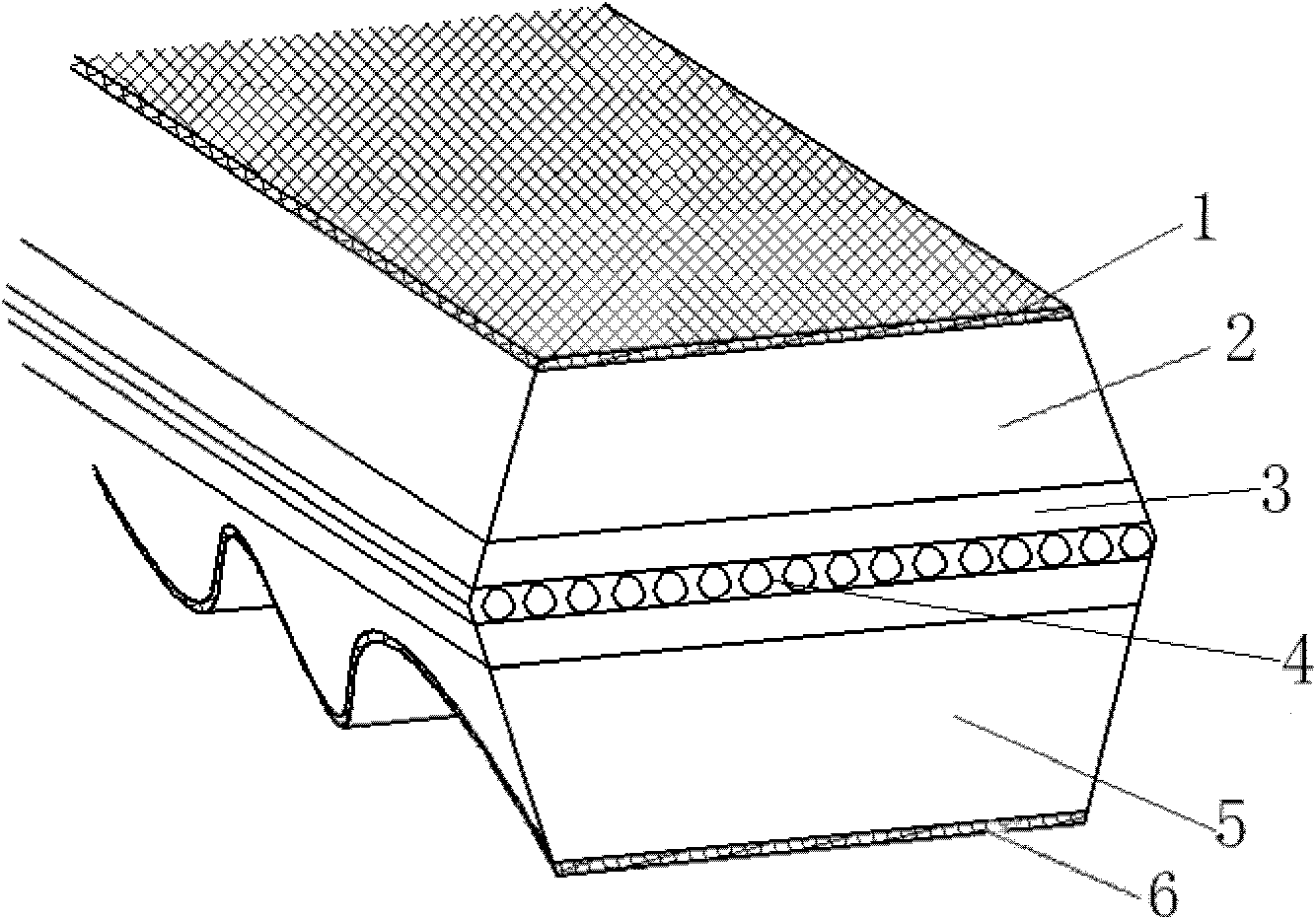

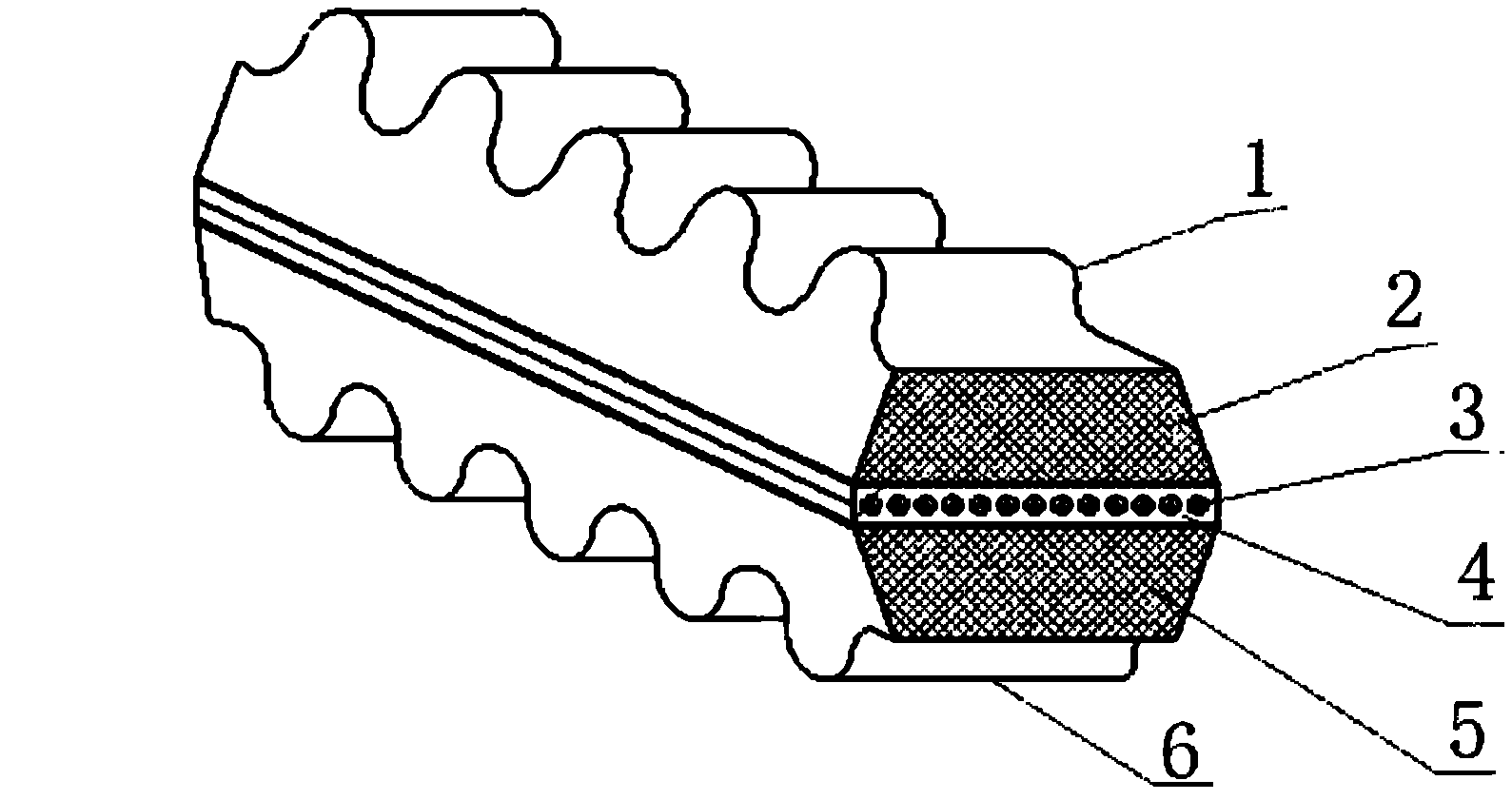

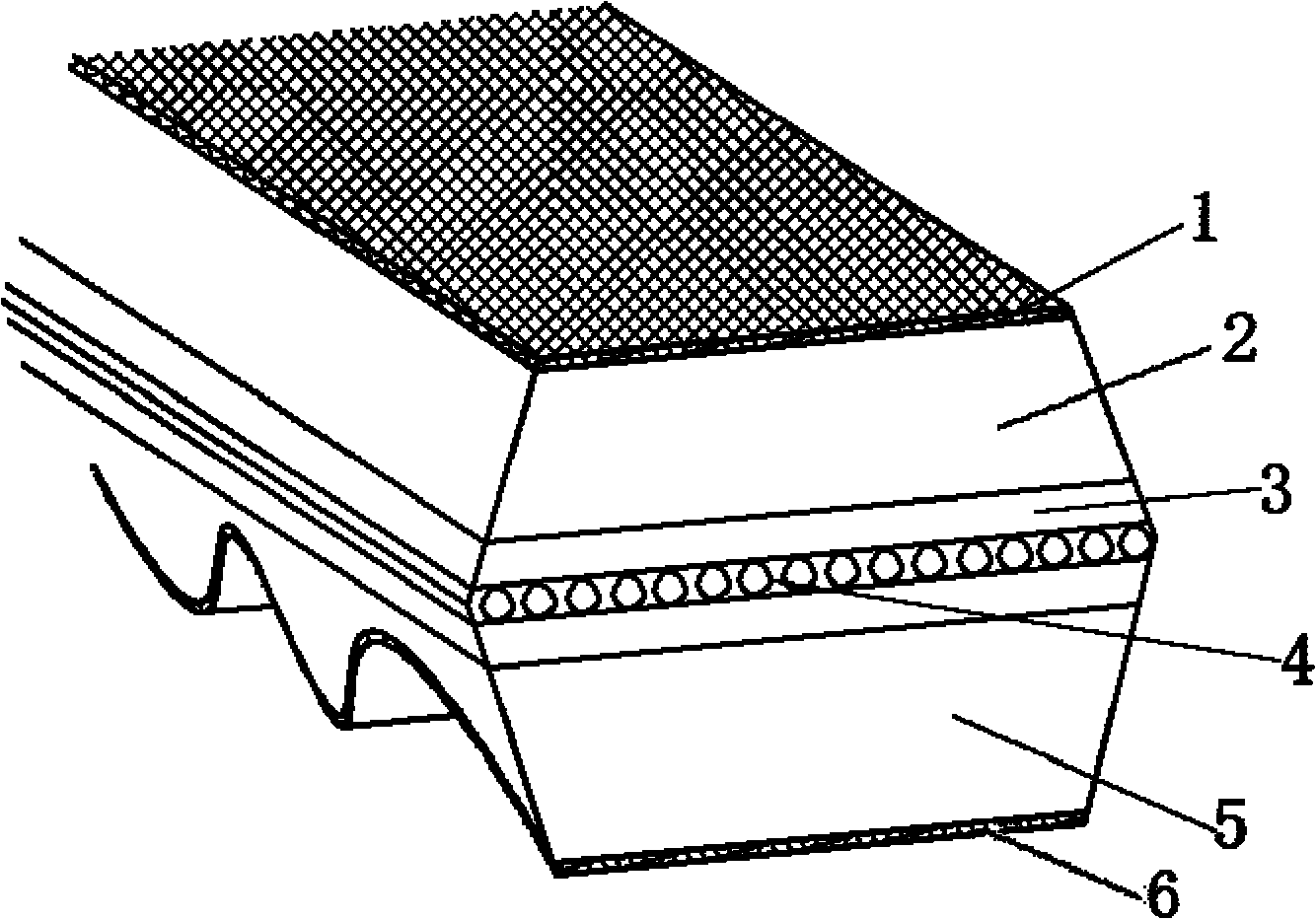

[0029] Combine below figure 1 Illustrating Embodiment 1 of the present invention, the product structure includes a strong layer in the middle and a top glue 2 and a bottom glue 5 respectively connected to the upper and lower sides of the strong layer. The top glue is provided with a top cloth 1, and the bottom glue There is a base cloth 6 below, and the top glue and the base glue are oriented short fiber rubber composite layers. The groups of short fibers in the oriented short fiber rubber composite layer are oriented in the transverse direction of the V-belt. The strength layer includes a buffer glue 3 and a cord structure 4 wrapped in the buffer glue and arranged in the direction of the V-belt transmission. The cord is a polyester cord. The top glue 2 is flat, and the outer surface of the bottom glue 5 is provided with a tooth-shaped structure.

[0030] The production process includes the following steps:

[0031] 1) Ingredients: weigh the raw calendered rubber, the comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com