Large high-pressure seamless rubber airbag and production process thereof

A technology of rubber airbags and production technology, which is applied in the direction of rubber layered products, sea area engineering, layered products, etc., can solve the problems of complex manufacturing process, low pressure resistance, and strict requirements for production equipment, so as to achieve simple operation of the production process, durability High compressive strength and good production stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

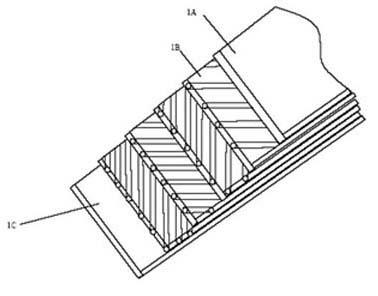

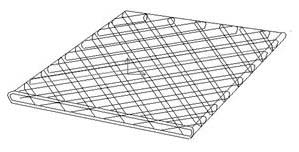

[0049] On the drum steel core of 5×Φ1.5M, according to the process method described in the specific implementation mode, four layers of high-strength cord skeletons are interlaced at 90-degree angles to form an angle of 46 degrees. The diameter of the cord fibers is 0.9mm, and the fibers are torn off individually. Strength 380N. When the airbag is not inflated, the flat size is 4×2m.

Embodiment 2

[0051] On the drum steel core of 6.8×Φ3M, according to the process described in the specific implementation method, there are four layers of high-strength cord skeletons interlaced at 90 degrees to each other at an angle of 56 degrees. The diameter of the cord fiber is 1.2mm, and the tearing strength of a single fiber is 500N. . When the airbag is not inflated, the flat size is 6×4m.

Embodiment 3

[0053] On the drum steel core of 6.8×Φ3M, according to the process described in the specific implementation method, there are 6 layers of high-strength cord skeletons interlaced at 90-degree angles to form 51-degree angles, the cord fiber diameter is 0.9mm, and the breaking strength of a single fiber is 380N . When the airbag is not inflated, the flat size is 6×4m.

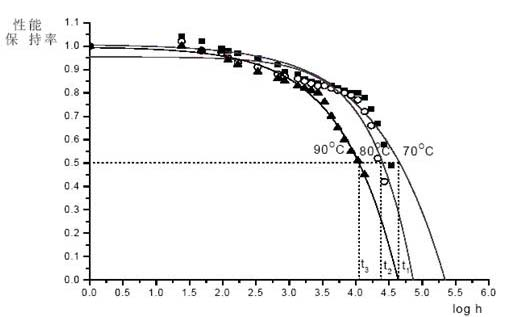

[0054] From Table 1, Table 2, Table 3 and the results of step 7 in the specific embodiment, it can be seen that the high-pressure seamless large-scale rubber airbag and the production process of the present invention are easy to operate and can meet the requirements of high-pressure, high-strength large-scale seamless rubber The products are molded and vulcanized at one time, and the production stability is good; the large-scale rubber airbags produced have high compressive strength (the operating pressure is above 0.8MPa), the service life exceeds 50 years, and the environmental sanitation index exceeds the natio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com