Strengthened and heat-conducting rubber for heavy truck tire shoulder

A technology for tire shoulders and automobiles, applied in special tires, vehicle parts, tire parts, etc., can solve the problems of mechanical properties decline, shortened service life, life and property loss, etc., achieve excellent physical and mechanical properties, and reduce tire shoulder voids. Damage and excellent workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

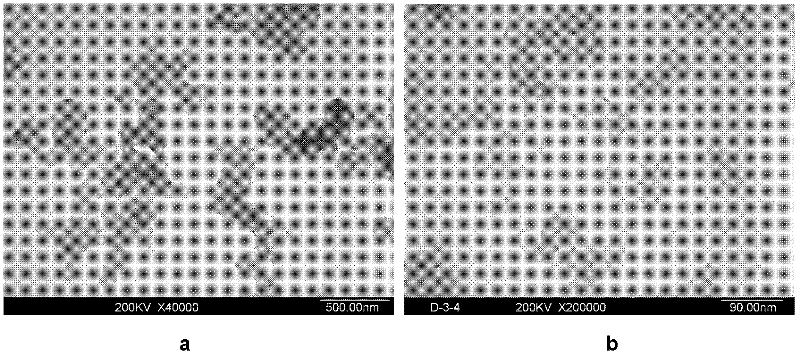

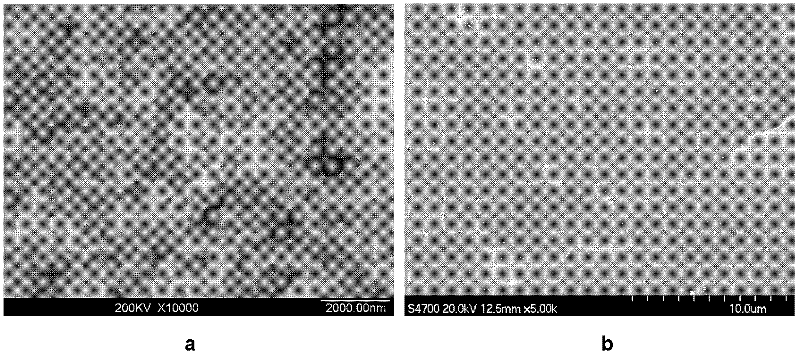

Image

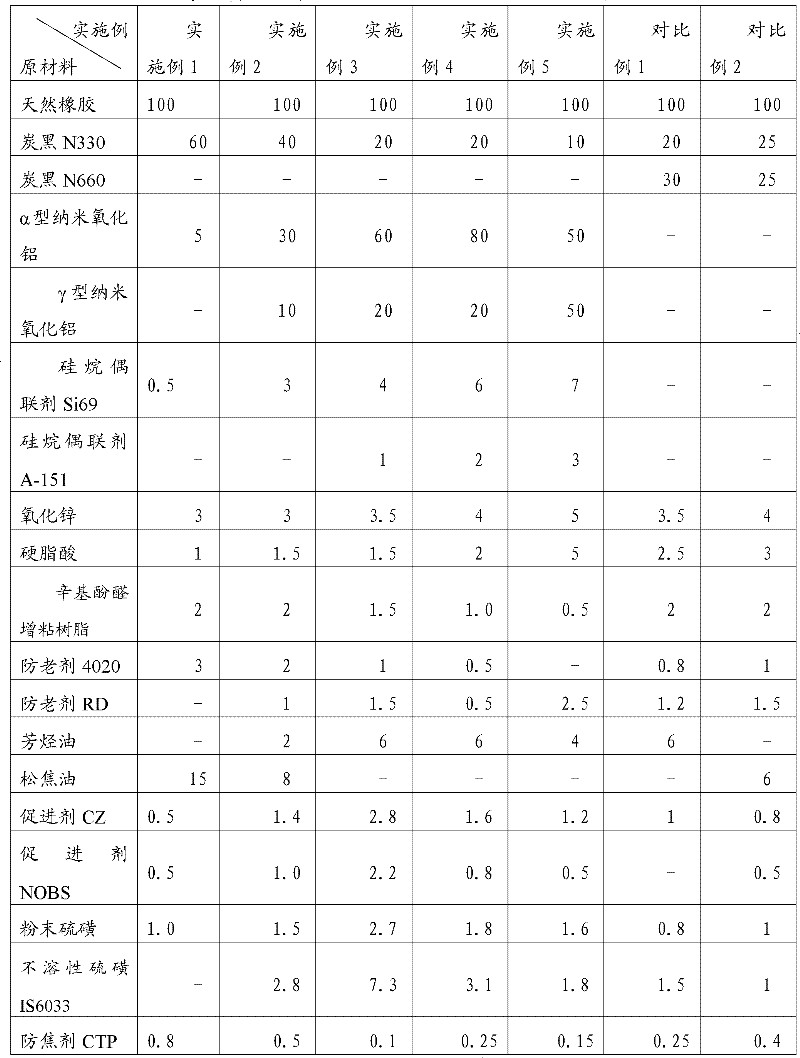

Examples

Embodiment Construction

[0034] The tensile strength and elongation at break of rubber composite materials for tire shoulders shall be determined according to GB-T528-1998.

[0035] The tear strength of rubber composite materials for tire shoulders shall be determined according to GB-T 529-1999.

[0036] The dynamic compression fatigue heat generation and compression set of rubber composite materials for tire shoulders are determined according to GB-T 1687-1993.

[0037] The thermal conductivity of rubber composite materials for tire shoulders shall be determined according to GB10294-2008.

[0038] Preparation method: 1) Add raw rubber to an internal mixer and masticate for 30 seconds; 2) Add carbon black, nano-alumina, stearic acid, zinc oxide, 203 resin, softener, silane coupling agent and anti-aging agent in sequence, Mix for 3-5 minutes, discharge when the temperature reaches 160°C, and cool to 45°C to form a cooled masterbatch; 3) Add the cooled masterbatch to the internal mixer, and add acceler...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com