Vibrating diaphragm for electro-acoustic system and preparation method of vibrating diaphragm

An electro-acoustic and rubber compounding technology, which is applied in the field of acoustic materials, can solve the problems of large permanent tensile change, high internal friction distortion, poor heat and cold resistance, etc., and achieves good molding consistency, simple processing technology, and improved The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031]

[0032]

[0033] The white carbon black in the above materials is selected: precipitated white carbon black with a specific surface area of 50m 2 / g, the particle size is 80 μm.

[0034] Add the above-mentioned materials into the banbury mixer in turn for banbury mixing, and then remove the glue after banbury mixing for 20 minutes. Fill the rubber into the mold, and then hot-press to form a diaphragm. The hot-press temperature is 90°C, the time is 30 minutes, and the pressure is 100Mpa.

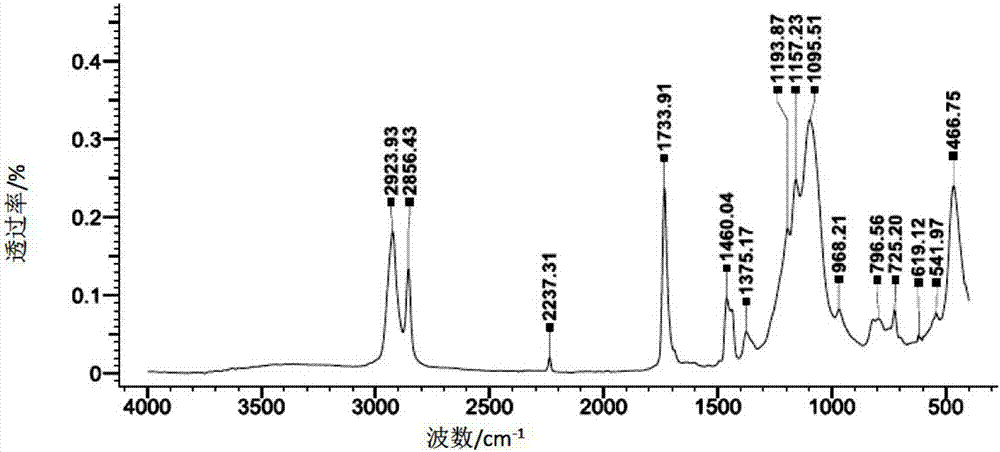

[0035] refer to figure 1 , the infrared spectrum of the diaphragm shows that the vibration peak of nitrile-C≡N appears at 2237.31cm -1 ; The vibration peak of the ester group-C=O is at 1733.91cm -1 ; The vibration peak of the ester group C-O is at 1193.87cm -1 and 1157.23cm -1 ; The vibration peak of Si-O-Si appears at 1095.51cm -1 place. It can be known that the raw rubber used to make the vibrating membrane contains nitrile groups and ester groups. The raw rubber can...

Embodiment 2

[0037]

[0038] The white carbon black in the above materials is selected: precipitated white carbon black, the specific surface area is 100m 2 / g, the particle size is 30 μm.

[0039] Put the above-mentioned materials into the internal mixer successively for internal mixing, and remove the glue after internal mixing for 10 minutes. Fill the rubber into the mold, and then hot-press to form a diaphragm. The hot-press temperature is 250°C, the time is 1 minute, and the pressure is 1Mpa.

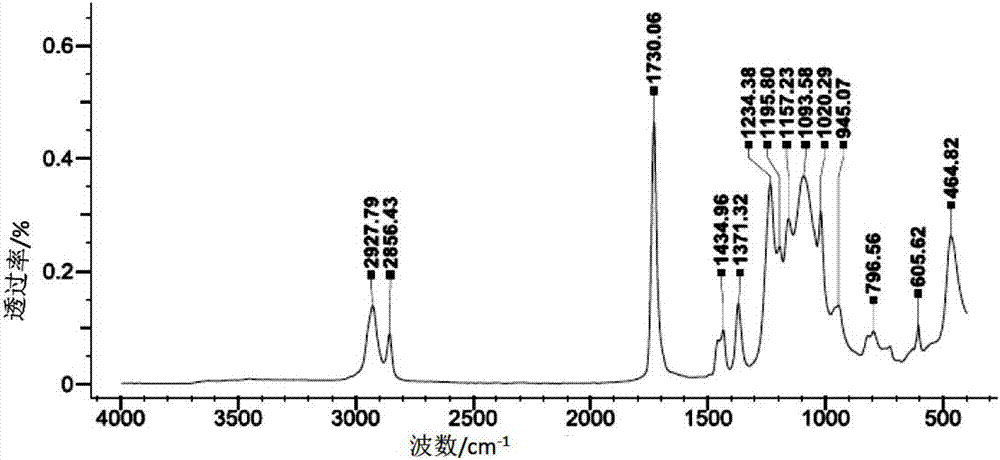

[0040] refer to figure 2 , the infrared spectrum of the diaphragm shows that the vibration peak of the ester group-C=O is at 1730.061cm -1 ; The vibration peak of the ester group C-O is at 1195.8cm -1 and 1157.23cm -1 、1234.38cm -1 and 1020.29cm -1 ; The vibration peak of Si-O-Si appears at 1093.58cm -1 place. It can be known that the raw rubber used to make the vibrating membrane contains ester groups, and the raw rubber may be composed of acrylate and ethylene vinyl acetate copoly...

Embodiment 3

[0042] Component Mass percentage % Raw rubber 50 Silica 45 aging agent 1 Processing aids 1 Vulcanization aid 1 Vulcanizing agent 2

[0043] The white carbon black in the above materials is selected: fumed white carbon black, the specific surface area range is 500m 2 / g, the particle size is 1nm.

[0044] Put the above-mentioned materials into the internal mixer successively for internal mixing, and remove the glue after internal mixing for 10 minutes. Fill the rubber into the mold, and then hot press to form a diaphragm. The hot pressing temperature is 200°C, the time is 2 minutes, and the pressure is 10Mpa.

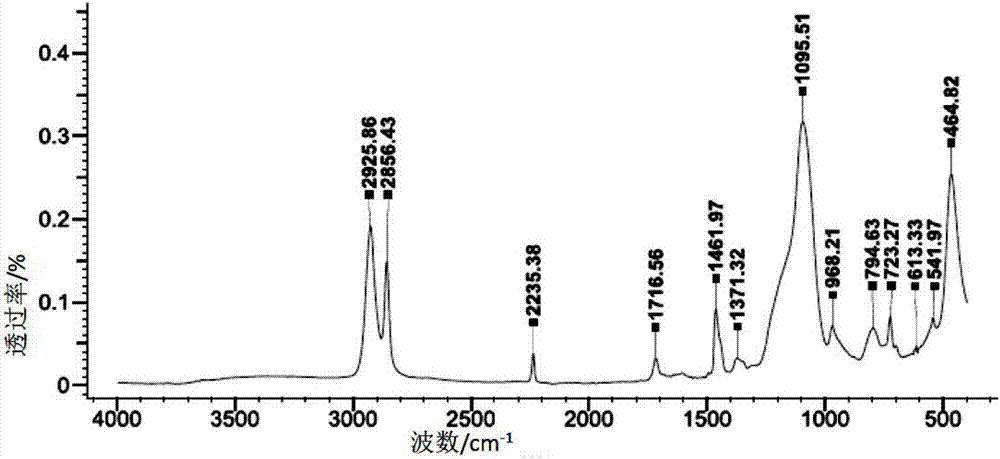

[0045] refer to image 3 , in the infrared spectrum of the diaphragm, the vibration peak of the nitrile group -C≡N appears at 2235.38cm -1, the vibration peak of Si-O-Si appears at 1093.58cm -1 place. It can be known that the raw rubber used to make the diaphragm contains nitrile groups, and may be composed of hydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com