Process and device for preparing graphene precursor two-dimension nanoscale graphite powder by adopting airflow crushing and peeling method

A two-dimensional nano, jet mill technology, used in grain processing and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

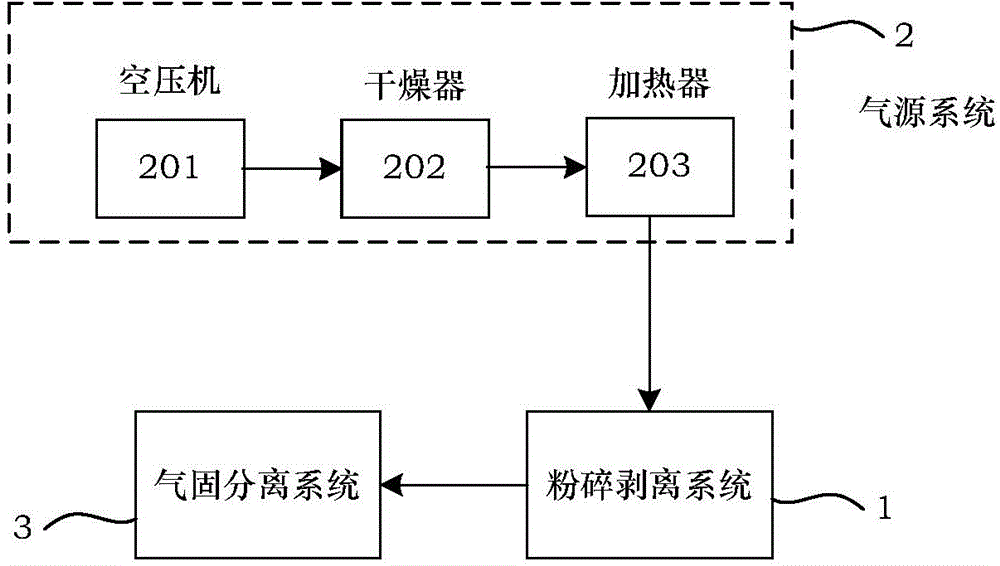

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] Example 1 Preparation of 85nm-thick two-dimensional nano-flaky graphite powder

[0077] The target component is flake graphite powder, which is 300 mesh flake graphite powder produced by Nanjing Xianfeng Nano Material Technology Co., Ltd.

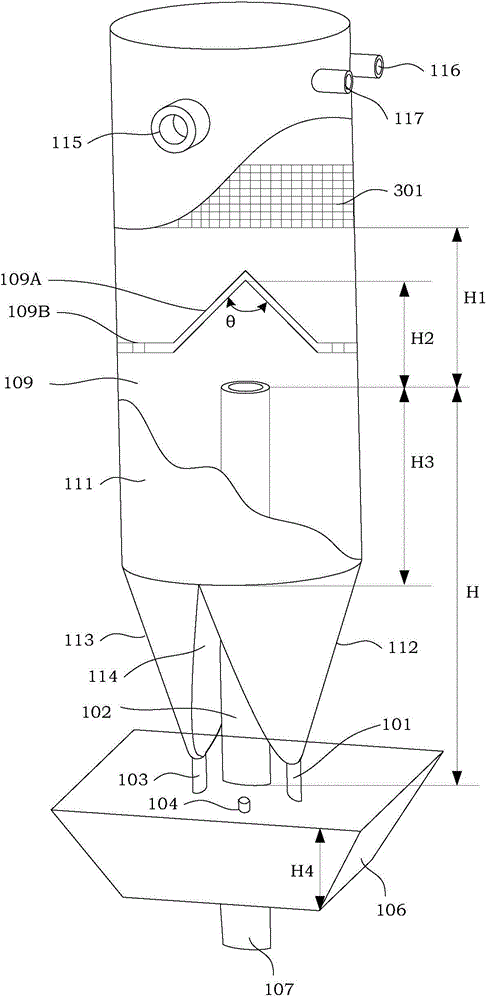

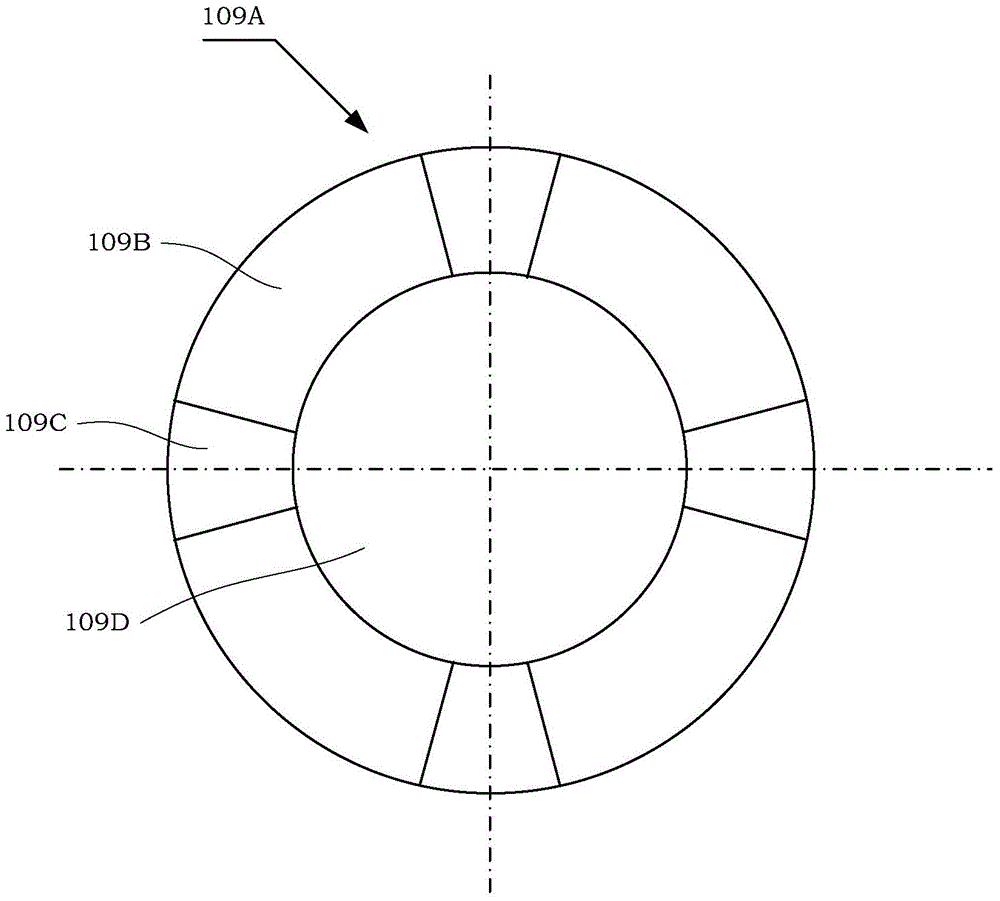

[0078] Adopting preparation technology and preparation device of the present invention to carry out pulverizing and exfoliating steps to graphite particle has:

[0079] The first step: the flake graphite powder particles are placed in the crushing and peeling chamber 106, and the amount of the flake graphite powder particles placed is 750 grams;

[0080] Second step: after drying the high-pressure gas (pressure 0.8 MPa) produced by the air compressor 201 in the drier 202, output the dry high-pressure gas; the output temperature is the dry high-pressure gas of 22 degrees;

[0081] The third step: cyclic continuous crushing and exfoliation of graphite particles

[0082] The A bleed pipe 104, B bleed pipe 105, and C bleed pipe 107 ...

Embodiment 2

[0085] Example 2 Preparation of 60nm-thick two-dimensional nano-flake graphite powder

[0086] The target component is flake graphite powder, which is 300 mesh flake graphite powder produced by Nanjing Xianfeng Nano Material Technology Co., Ltd.

[0087] Adopting preparation technology and preparation device of the present invention to carry out pulverizing and exfoliating steps to graphite particle has:

[0088] The first step: the flake graphite particles are placed in the crushing and peeling chamber 106, and the amount of flake graphite particles placed is 750 grams;

[0089] Second step: after drying the high-pressure gas (pressure 0.8 MPa) produced by the air compressor 201 in the drier 202, output the dry high-pressure gas; the output temperature is the dry high-pressure gas of 60 degrees;

[0090] The third step: cyclic continuous crushing and exfoliation of graphite particles

[0091] The A bleed pipe 104, B bleed pipe 105, and lower nozzle 106A of the crushing a...

Embodiment 3

[0092] Example 3 Add tetraisopropyl bis(dioctyl phosphite) titanate coupling agent (NDZ-401) to prepare 75 nm thick two-dimensional nano-sheet graphite powder

[0093] The target component is flake graphite powder, which is 300 mesh flake graphite powder produced by Nanjing Xianfeng Nano Material Technology Co., Ltd.

[0094] The ratio of flake graphite powder to tetraisopropyl bis(dioctyl phosphite) titanate coupling agent (NDZ-401) is 98:2;

[0095] Stir at 2900 rpm for 30 minutes on a high-speed mixer to obtain a mixed premix; Zhangjiagang Qiangqiang Plastic Machinery Co., Ltd., SHR-5A high-speed mixer.

[0096] Then the mixed premix was treated with the same crushing and exfoliating steps as in Example 1 for 2 hours, and the lateral size of the exfoliated flake graphite powder was 1-5 microns, and the thickness of the particles was about 73 nanometers.

[0097] The present invention utilizes the improved jet crushing and stripping device to process the graphene precurs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com