Method for preparing spherical cobalt hydroxide in the absence of complexing agent

A cobalt hydroxide and complexing agent technology, applied in the direction of cobalt oxide/cobalt hydroxide, etc., can solve the problems of long process, harsh drying conditions, increased consumption of carbonate or bicarbonate, etc., and achieve strong oxidation resistance, The reaction conditions are simple and easy to control, and the effect of easy filtration and washing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Prepare 10L of cobalt sulfate solution (metal content) with a concentration of 30g / l and 4L of sodium hydroxide solution with a concentration of 120g / l, add 2L of pure water to a reaction kettle with a volume of 20L, heat up to 60°C, and then Add cobalt liquid and sodium hydroxide solution in parallel, maintain the pH value of 6-7 during the feeding process, and obtain a uniformly dispersed blue precipitate; continue to add sodium hydroxide solution until the final pH value is 13.5, add 4g of butyl hydroxy anise Ether solid is used as a protective agent, the reaction time is about 3 hours, after aging for half an hour, it is filtered and washed, and then the filter cake is dried in a flash dryer at 150°C to obtain the product β-Co(OH) 2 .

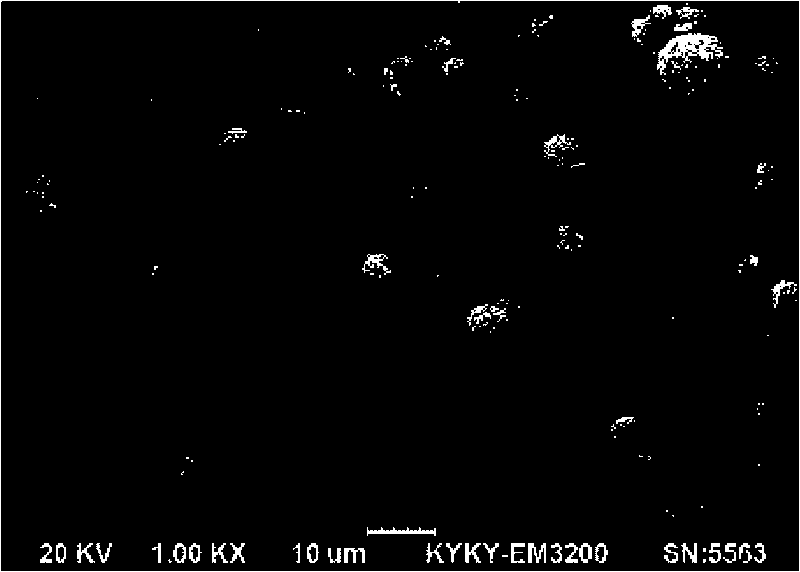

[0022] The pink cobalt hydroxide that obtains, cobalt content is 62.21% (mass), bulk density is 0.43g / cm 3 . From the SEM image (see figure 1 ) It can be seen that the product is a spherical particle with an average particle diame...

Embodiment 2

[0024] Prepare 2L of cobalt sulfate solution (metal content) with a concentration of 160g / l and 12L of sodium hydroxide solution with a concentration of 40g / l, add 2L of pure water to a reaction kettle with a volume of 20L, heat up to 60°C, and then Add cobalt liquid and sodium hydroxide solution in parallel, maintain the pH value of the feeding process at 5-6, and obtain a uniformly dispersed blue precipitate; continue to add sodium hydroxide solution to the final pH value of 10.5, add 4g of tert-butyl to Hydroquinone solid is used as protective agent, after aging for half an hour, it is filtered and washed, and then the filter cake is dried in a flash dryer at 240°C to obtain the product.

[0025] The obtained pink cobalt hydroxide has a cobalt content of 62.43% and a bulk density of 0.34g / cm 3 . The product is spherical particles with an average particle size of 30 μm.

Embodiment 3

[0027] Prepare 4L of cobalt sulfate solution (metal content) with a concentration of 90g / l and 8L of sodium hydroxide solution with a concentration of 90g / l, add 2L of pure water to a reaction kettle with a volume of 20L, heat up to 60°C, and then Add cobalt liquid and sodium hydroxide solution in parallel flow, maintain the pH value of the feeding process at 5-6, and obtain a uniformly dispersed blue precipitate; continue to add sodium hydroxide solution to the final pH value of 12.6, add 4g of dibutyl hydroxyl The toluene solid is used as a protective agent, after aging, it is filtered and washed, and then the filter cake is adjusted to a slurry with a certain fluidity by adding an appropriate amount of water, and dried at 300°C in a spray dryer to obtain the product.

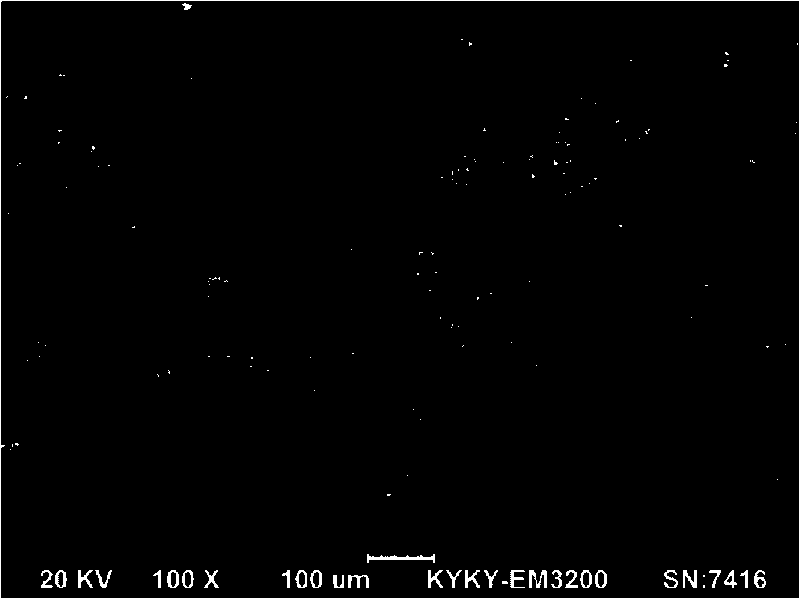

[0028] The pink cobalt hydroxide has a cobalt content of 62.32% and a bulk density of 0.65g / cm 3 . From the SEM image (see figure 2 ) It can be seen that the product is a spherical particle with an average...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bulk density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com