Reducing reagent nozzle for denitration by SNCR method

A reducing agent and nozzle technology, which is applied in the field of nozzles for injecting reducing agent, can solve the problems of uneven distribution of droplets, short range, rising cost, etc., and achieve the effects of good penetration performance, narrow temperature range and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

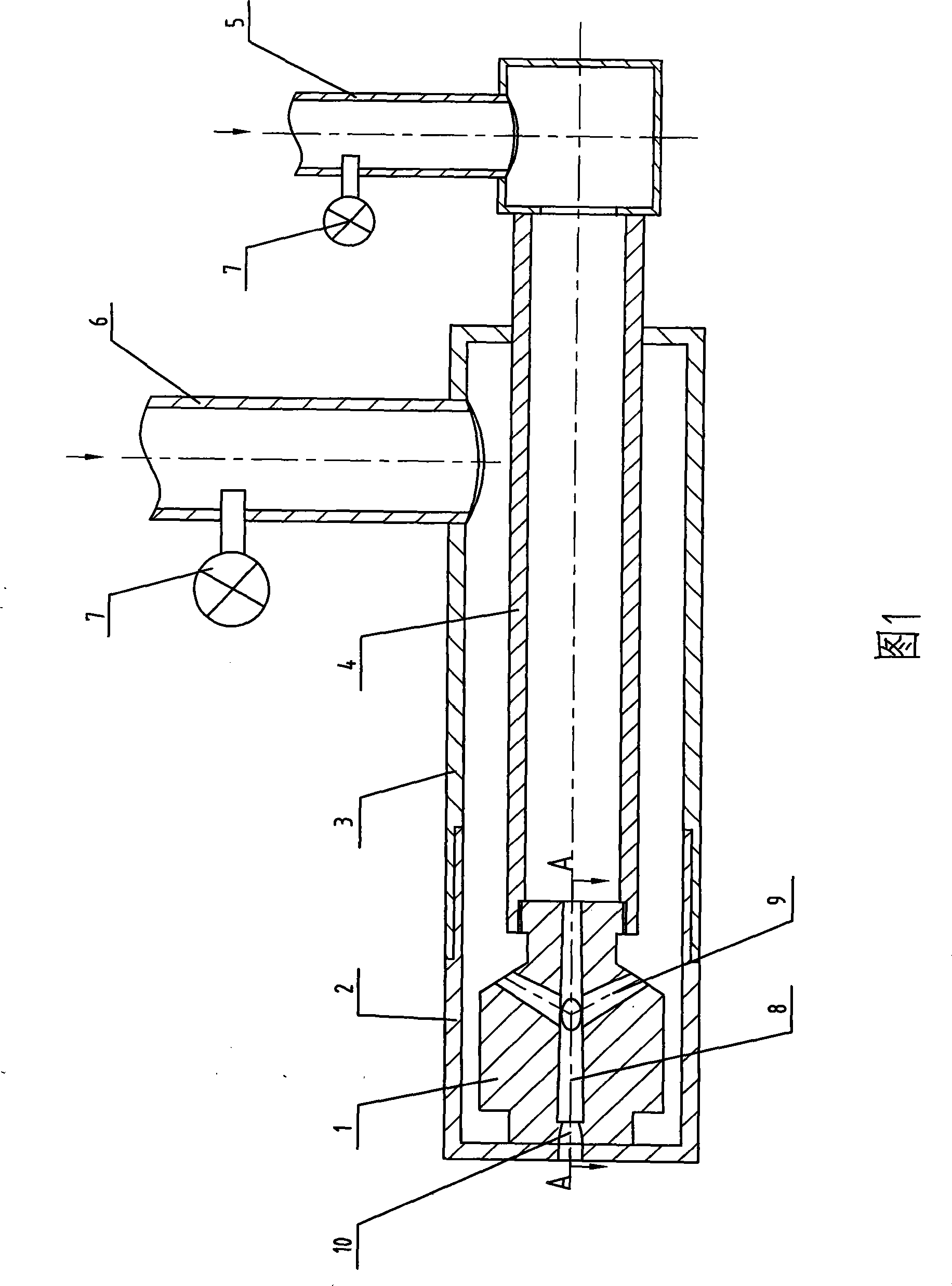

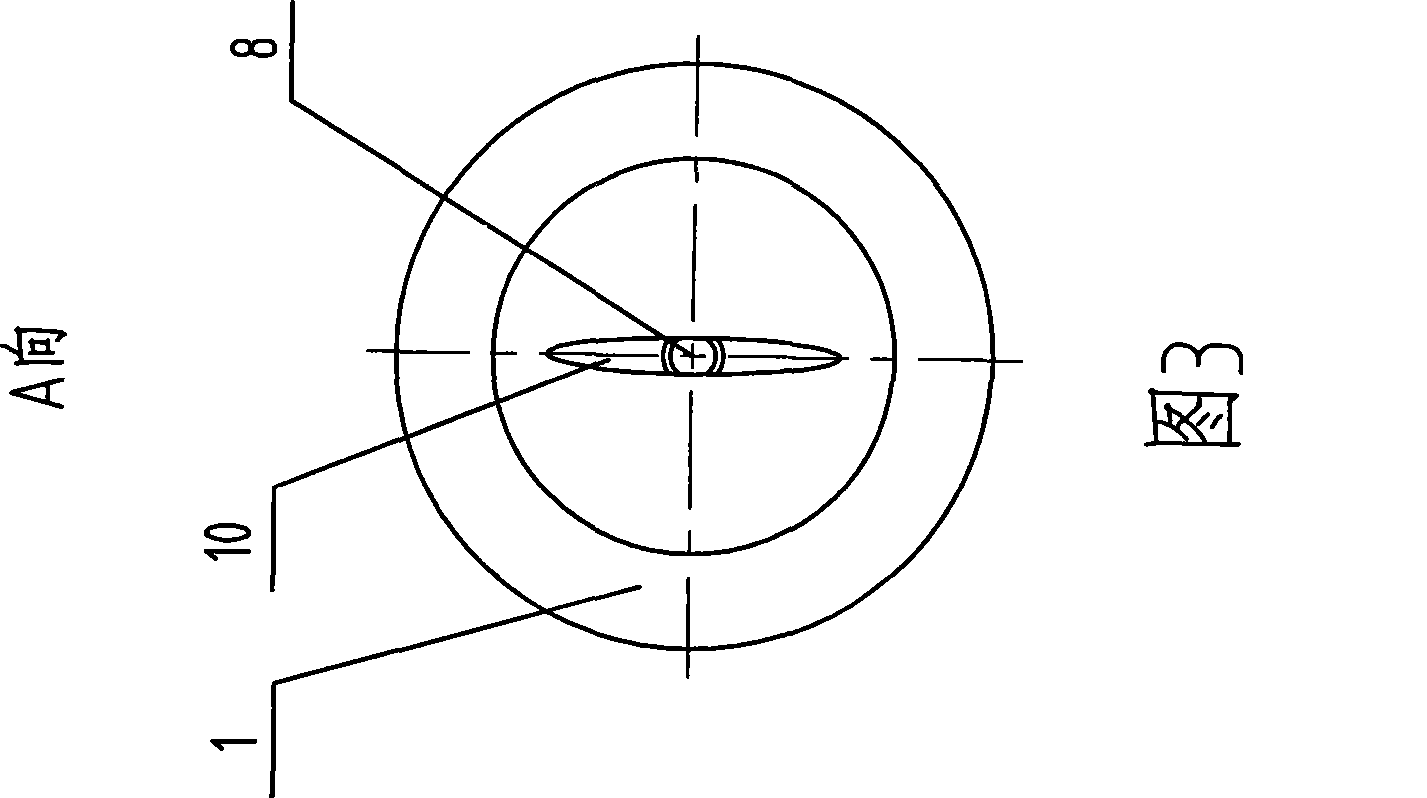

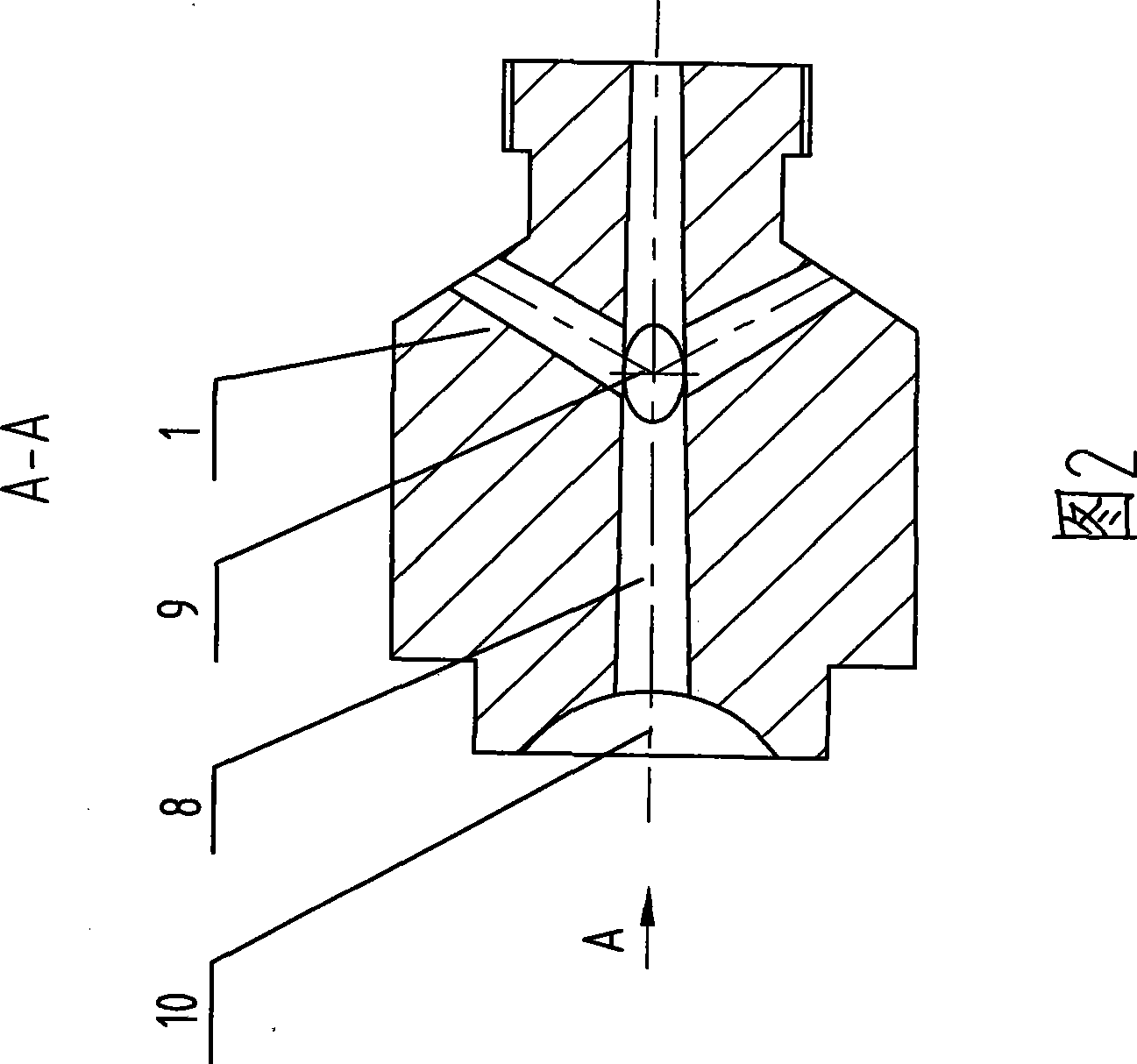

[0017] The present invention comprises a main pipe 4, a secondary pipe 3, a ferrule 2, a liquid flow pipe I5, a liquid flow pipe II6 and a nozzle 1, the ferrule 2 and the secondary pipe 3 are connected by threads to form a relatively airtight space, and the front end of the main pipe 4 is equipped with a nozzle 1, and placed in the auxiliary pipe 3, the front end of the nozzle 1 is in contact with the ferrule 2; the rear end of the main pipe 4 is connected with the liquid flow pipe I5 with a pressure gauge 7; the auxiliary pipe 3 is connected with the pressure gauge 7 The liquid flow tube II6 is connected; the nozzle 1 is provided with a mixing hole 8 passing through the main pipe 4 in the axial direction. The nozzle 1 is also provided with four branch holes 9 communicating with the mixing hole 8 and the auxiliary pipe 3. The branch holes 9 are also tape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com