Method for synthesizing rare-earth oxide sulfate nano-grain by high-molecular gel network template

A technology of rare earth sulfur oxide and polymer gel, which is applied in the field of material science, can solve the problems of high cost and complicated process of microemulsion, and achieve the effect of low cost, high phase purity and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

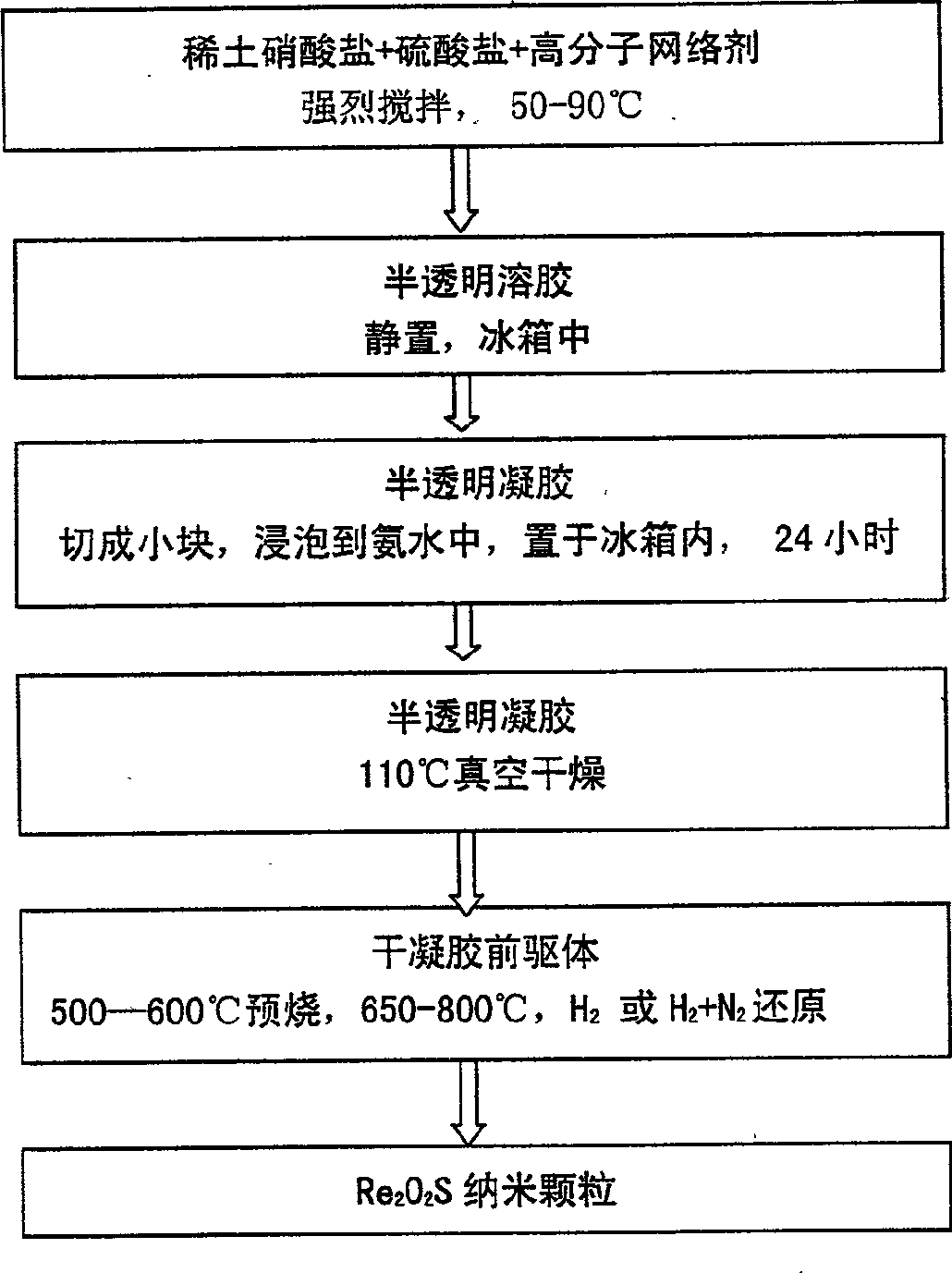

Method used

Image

Examples

Embodiment 1

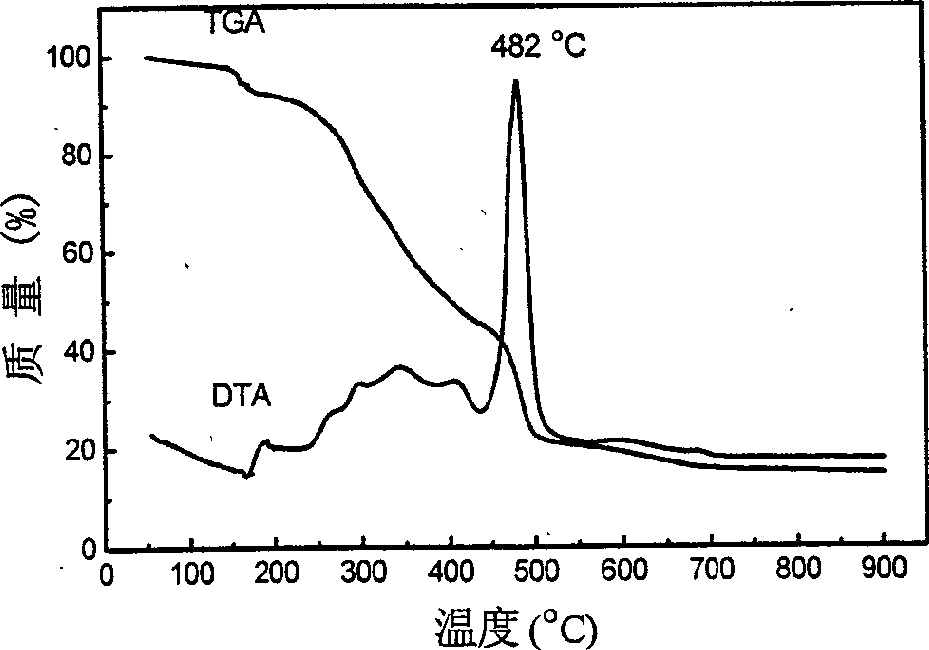

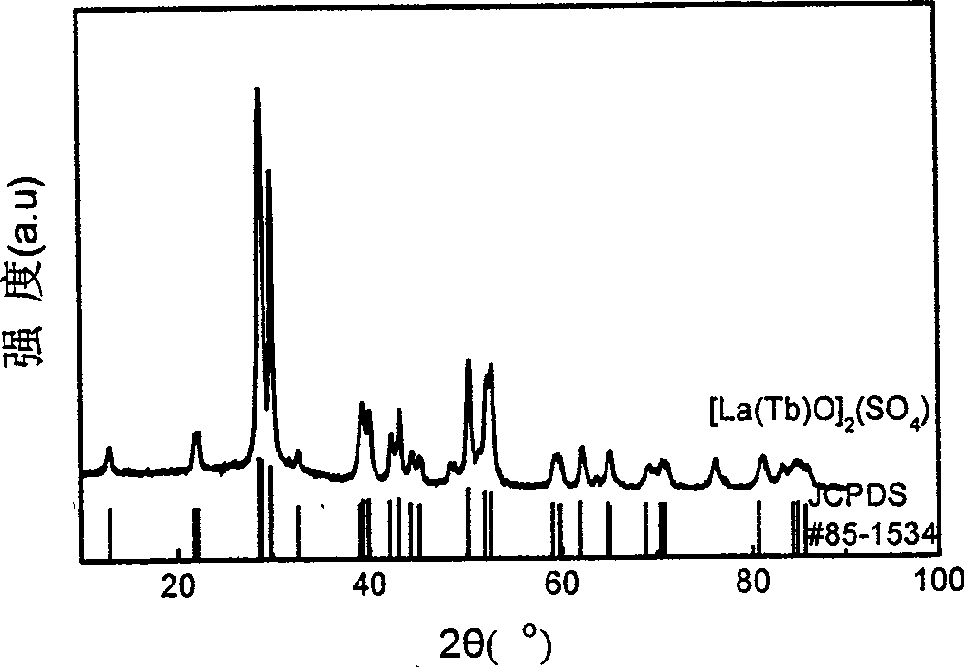

[0034] 0.2M La(NO 3 ) 3 and Tb(NO 3 ) 3 The solution is mixed according to the molar ratio La:Tb=95:5, and 0.5M ammonium sulfate [(La+Tb):SO is added 4 2- =2:1 molar ratio)] and polymer reticulating agent (gelatin 15wt%) were vigorously stirred and mixed evenly, and a translucent sol was formed at 80°C. The sol was allowed to stand at room temperature, and then placed in a refrigerator at 4°C to form a gel. Cut the gel into 1cm cubes, soak in 4mol / l ammonia water, wash with cold water after 24 hours, and dry under vacuum at 110°C for 3 hours. Heating the dry gel at 500°C in air in a tube furnace and keeping it warm for 2 hours, and then reducing it in a hydrogen atmosphere at 650, 700, 750 and 800°C for 1 hour to obtain rare earth sulfur oxide nanoparticles. Gained nanoparticle is carried out test and analysis result is as follows:

[0035] Xerogel TG-DTA curve figure 2 It can be seen that gelatin has a high decomposition temperature (482°C) and a narrow temperature r...

Embodiment 2

[0045] 0.3M La(NO 3 ) 3 and Pr(NO 3 ) 3 The solution is mixed according to the molar ratio La:Pr=98:2, and 1.0M ammonium sulfate [(La+Pr):SO is added 4 2- =2:1 molar ratio)] and the polymer network agent (gelatin 10wt%) were vigorously stirred and mixed evenly, and a translucent sol was formed at 85°C. The sol was allowed to stand at room temperature, and then placed in a refrigerator at 4°C to form a gel. Cut the gel into 2cm cubes, soak in 8mol / l ammonia water, wash with cold water after 24 hours, and dry in vacuum at 110°C for 4 hours. Heating the dry gel at 500°C in air in a tube furnace and keeping it warm for 2 hours, and then reducing it in a hydrogen atmosphere at 750°C for 1 hour to obtain La 2 o 2 S:2mol%Pr 3+ nanoparticles, spectra such as Figure 7 .

Embodiment 3

[0047] 0.2M La(NO 3 ) 3 and Eu(NO 3 ) 3 The solution is mixed according to the molar ratio La:Eu=98:2, and 1.0M ammonium sulfate [(La+Pr):SO is added 4 2- =2:1 molar ratio)] and the polymer network agent (gelatin 15wt%) were vigorously stirred and mixed evenly, and a translucent sol was formed at 70°C. The sol was allowed to stand at room temperature, and then placed in a refrigerator at 4°C to form a gel. Cut the gel into 1cm cubes, soak in 8mol / l ammonia water, wash with cold water after 24 hours, and dry in vacuum at 110°C for 4 hours. Heat the dry gel at 500°C in air in a tube furnace and keep it warm for 2 hours, then hydrogen + nitrogen at 750°C (volume ratio H 2 :N 2 =2:1) Reduction in atmosphere for 1 hour to get La 2 o 2 S:2mol%Eu 3+ nanoparticles, spectra such as Figure 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com