Forming method for protecting image

A technology for protecting graphics and graphics, applied in the field of forming protection graphics, can solve the problems of low degree of freedom, increased sensitivity, and reduced degree of freedom of protective materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

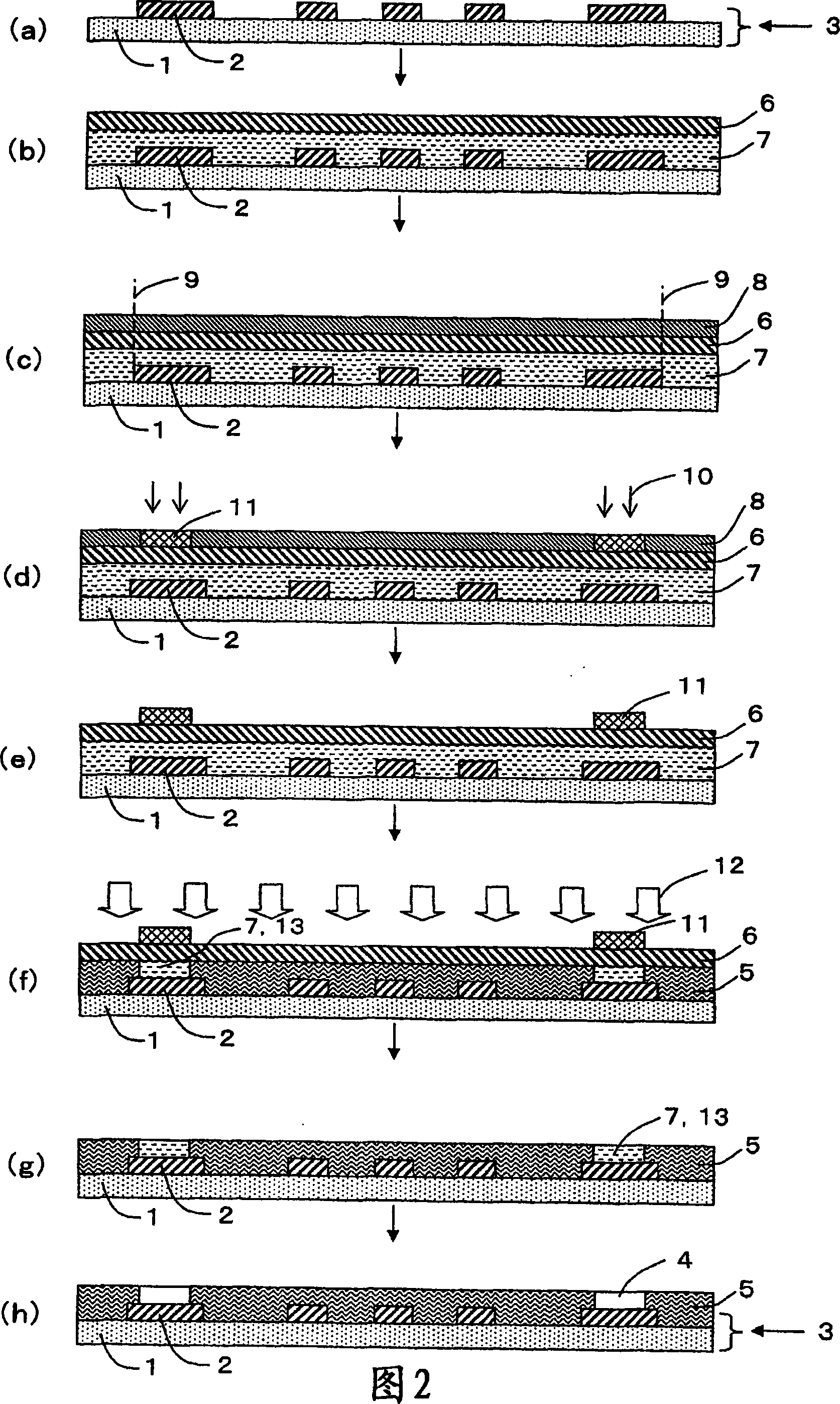

[0161] First, use a 150-mesh polyester screen to uniformly disperse the following ingredients 1) The resin composition was printed on a PE film 14 with a thickness of 100 μm, and dried at 80° C. for 15 minutes. In this way, the second photocurable protective film 8 is formed on the PE film 14 . Thereafter, a PET masking film 6 having a thickness of 25 μm was laminated on the upper surface of the second photocurable protective film 8 . In this way, a three-layer body composed of the PE film 14, the second photocurable protective film 8, and the PET masking film 6 was produced (see FIG. 6(a)).

[0162] On the other hand, the following combination composition 2) Alkali-developing type solder resist is screen-printed on the printed wiring board 3 on which the wiring pattern 2 has been formed, and the first photocurable protective film 7 is formed on the printed wiring board 3 (see FIG. 6(b) ).

[0163] Next, the above-mentioned three-layer body was laminated on the first photo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com