Installation method of shunt module cabinet body upper support frame piece and positioning tool for installation

A technology for positioning tooling and splitter, applied in auxiliary devices, manufacturing tools, metal processing equipment, etc., can solve problems such as affecting the company's reputation, displacement, damage to splitter modules, etc., to reduce repair time and labor costs, Improve economic efficiency and not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited only to the examples.

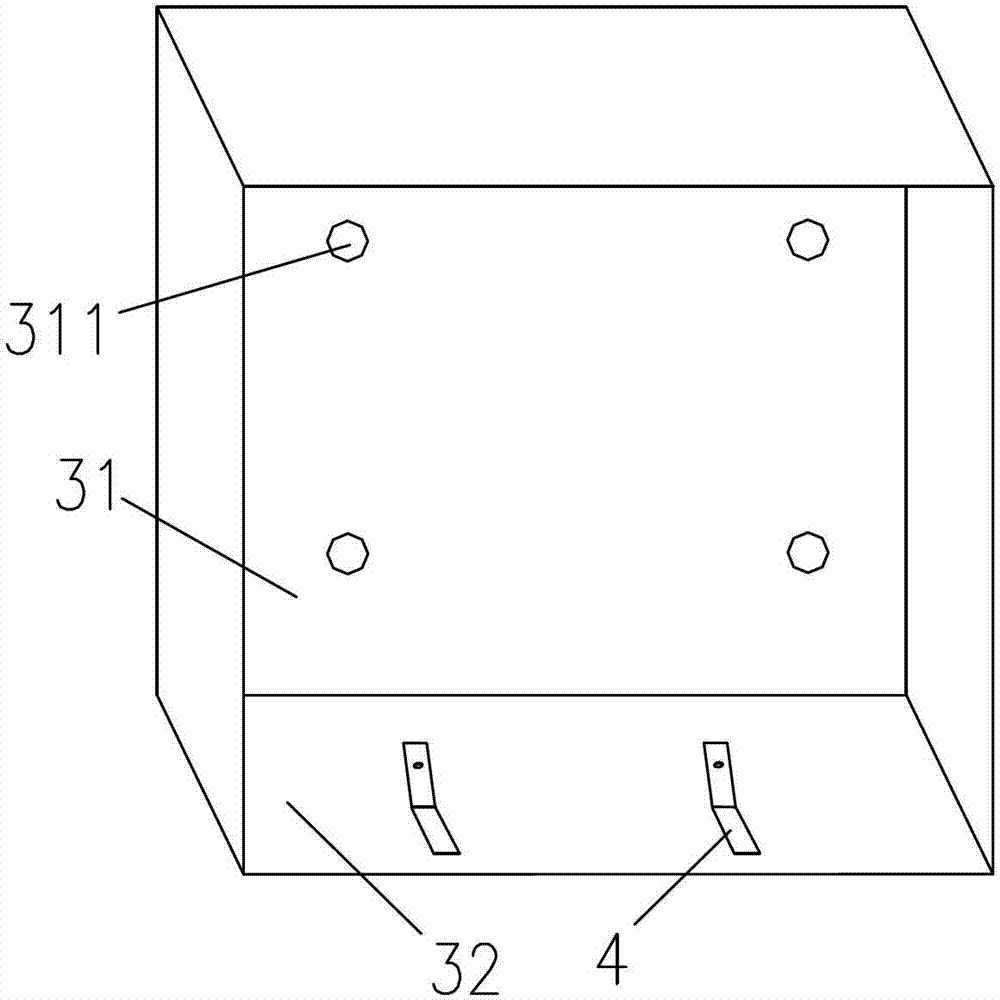

[0026] Such as figure 1 As shown, the splitter module cabinet has a side wall 31 and a top plate 32 , four mounting holes 311 are provided on the side wall 31 , and two support pieces 4 are provided on the top plate 32 .

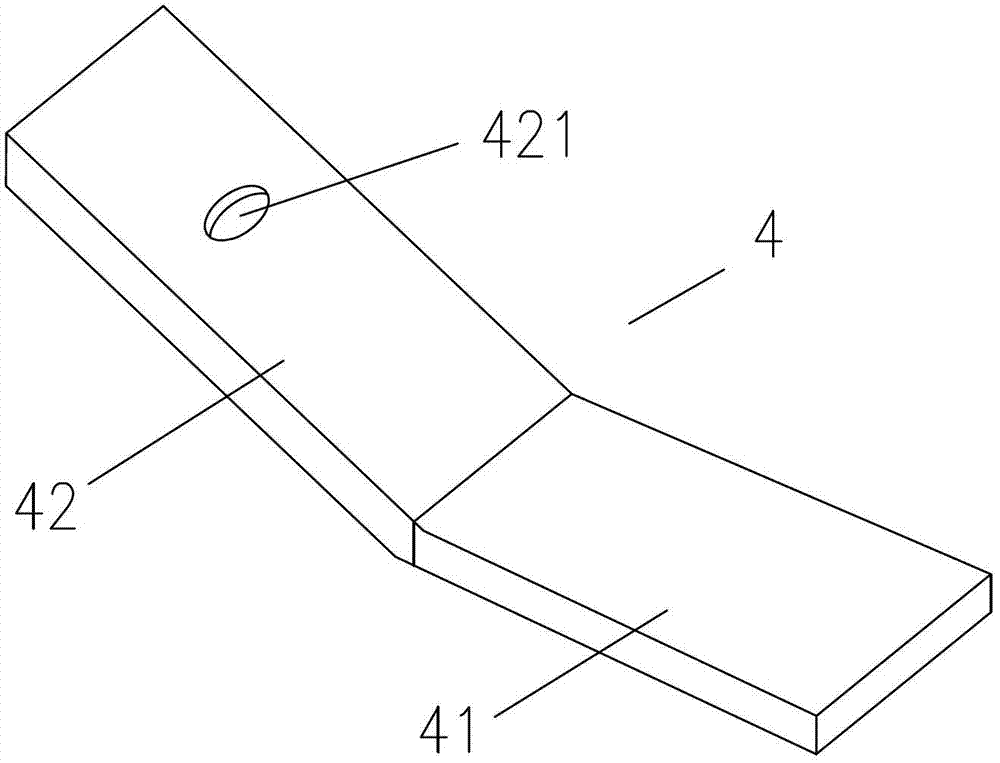

[0027] Such as figure 2 As shown, the bracket piece 4 has a first plate 41 and a second plate 42, the second plate 42 is provided with a threaded hole 421, and the inner circle of the threaded hole 421 is provided with threads, which is convenient for screwing in. There is an angle between the first sheet 41 and the second sheet 42, and the bracket sheet 4 is actually formed by one-time stamping.

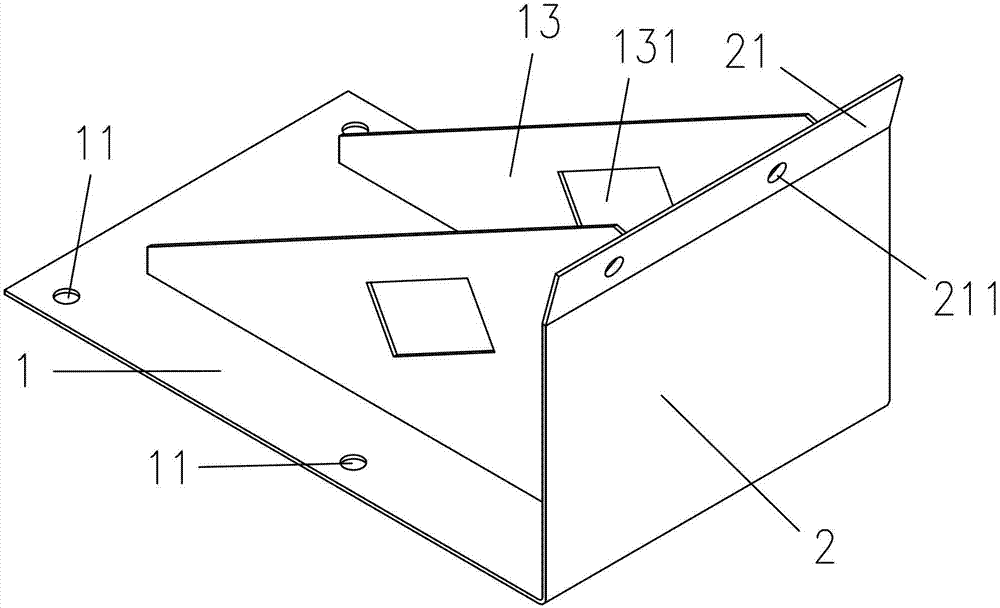

[0028] Such as image 3 As shown, the positioning tool includes a vertical plate 1 , a horizontal plate 2 , a positioning plate 21 and several connecting plates 13 . The vertica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com