Forming method for protecting image

A technology for protecting graphics and graphics, applied in the field of forming protection graphics, can solve the problems of low degree of freedom of protection materials, less non-exposed parts, and reduced degrees of freedom, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

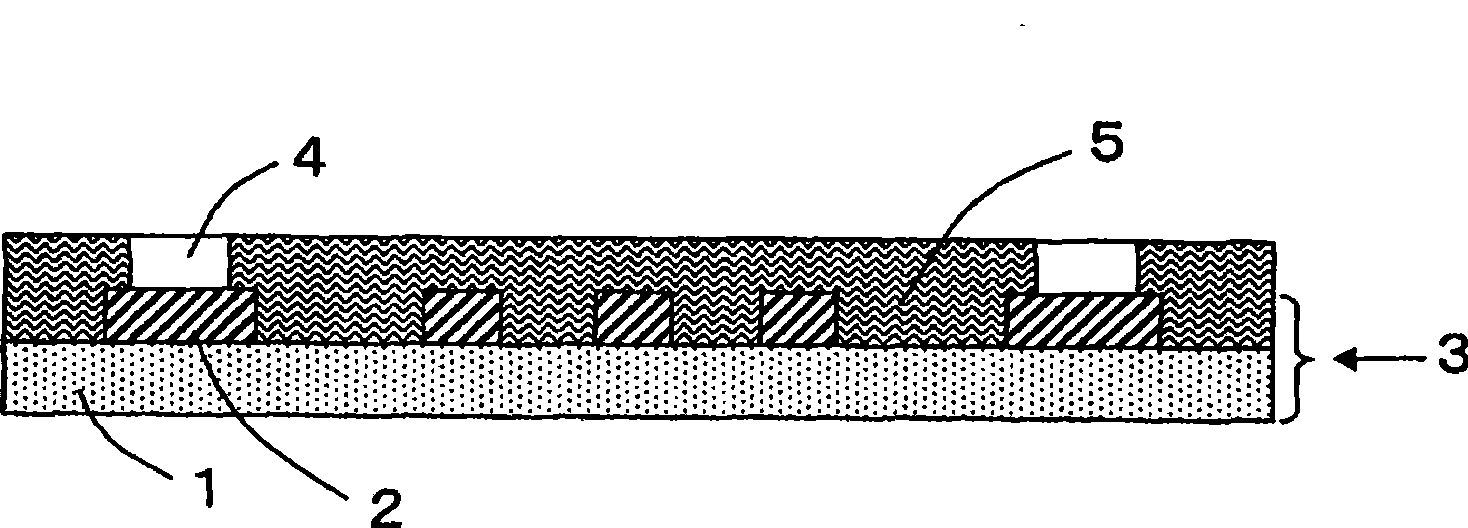

Image

Examples

Embodiment 1

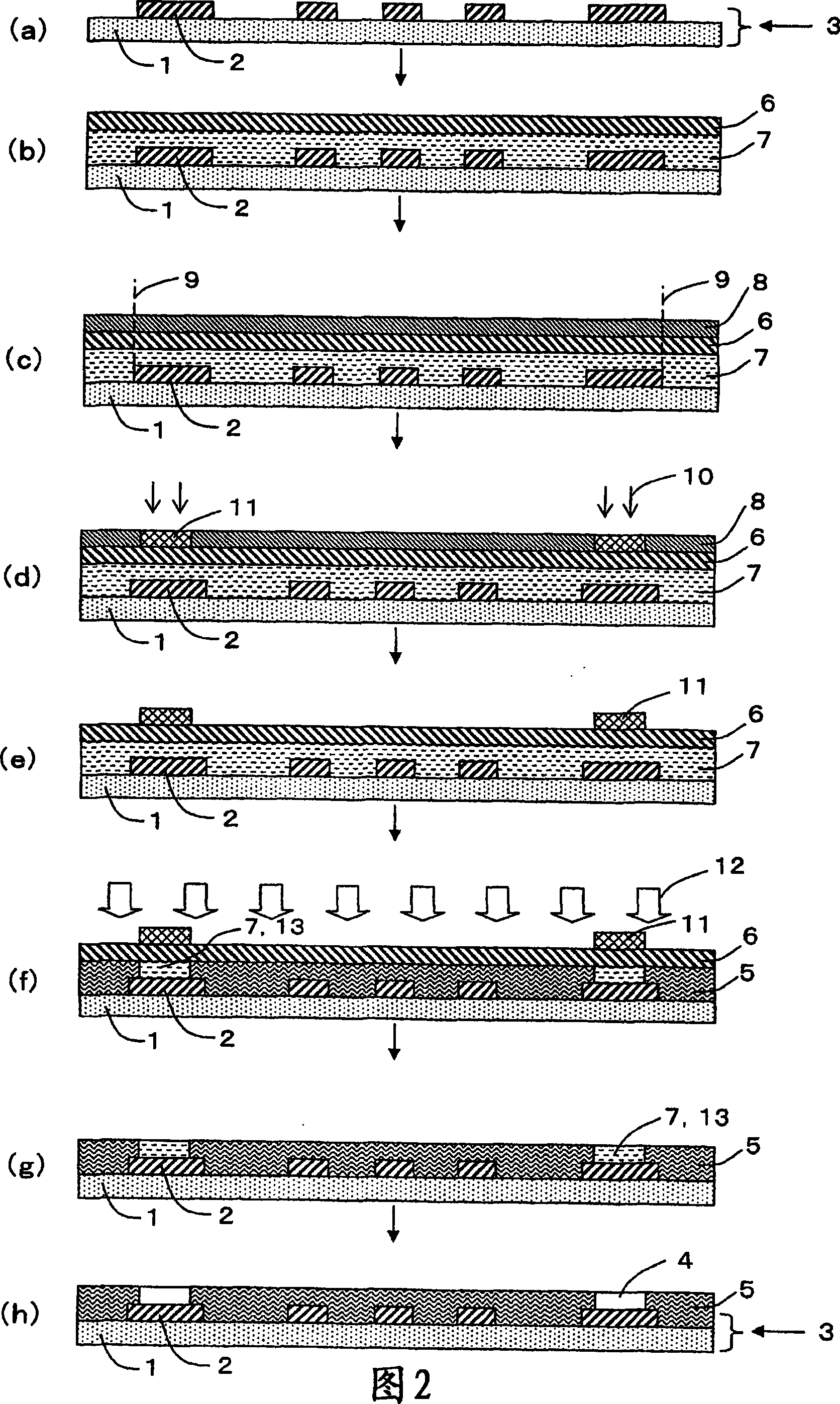

[0161] First, use a 150-mesh polyester screen to uniformly disperse the following ingredients 1) The resin composition was printed on a PE film 14 with a thickness of 100 μm, and dried at 80° C. for 15 minutes. In this way, the second photocurable protective film 8 is formed on the PE film 14 . Thereafter, a PET masking film 6 having a thickness of 25 μm was laminated on the upper surface of the second photocurable protective film 8 . In this way, a 3-layer body consisting of the PE film 14, the second photocurable protective film 8 and the PET cover film 6 is made (refer to Figure 6 (a)).

[0162] On the other hand, the following combination composition 2) Alkali developing type solder resist is screen-printed on the printed wiring board 3 on which the wiring pattern 2 has been formed, and the first photocurable protective film 7 is formed on the printed wiring board 3 (refer to Figure 6 (b)).

[0163] Next, the above-mentioned three-layer body was laminated on the fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com