Etching method

An etching and resist film technology, applied in lithography masks, patterns, lithography, resist parts and other directions, can solve problems such as poor yield, and achieve the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, one embodiment of the present invention will be described with reference to the drawings.

[0025] First, the structure of the processed product manufactured by the etching method of this embodiment is demonstrated.

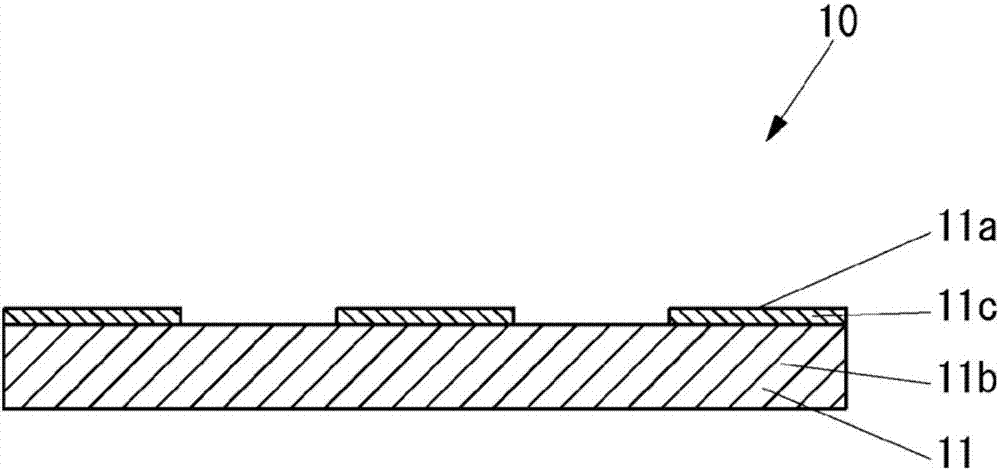

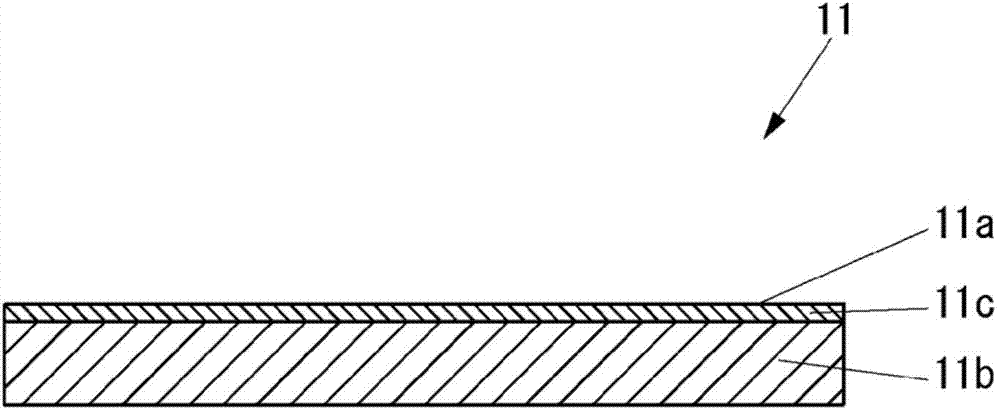

[0026] figure 1 It is a side sectional view of the processed product 10 manufactured by the etching method of this embodiment.

[0027] Such as figure 1 As shown, the processed product 10 is an article produced by denting the surface 11 a of the object 11 . For example, the processed product 10 is a printed wiring board in which a conductor layer 11c which is a conductor layer such as copper is coated on an insulator base material 11b.

[0028] Next, the configuration of the inkjet printer used to manufacture the processed product 10 will be described.

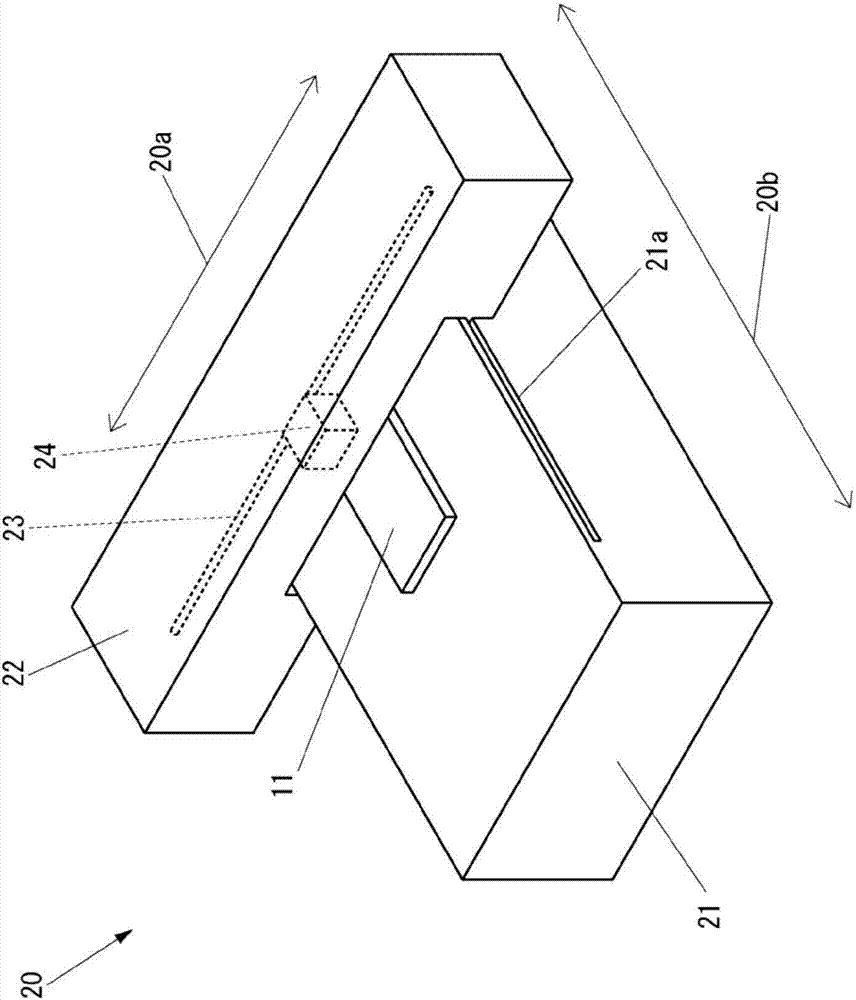

[0029] figure 2 It is a perspective view of the inkjet printer 20 for manufacturing the processed product 10 .

[0030] Such as figure 2 As shown, the inkjet printer 20 includes a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com