Patents

Literature

34results about How to "Reduce plating area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

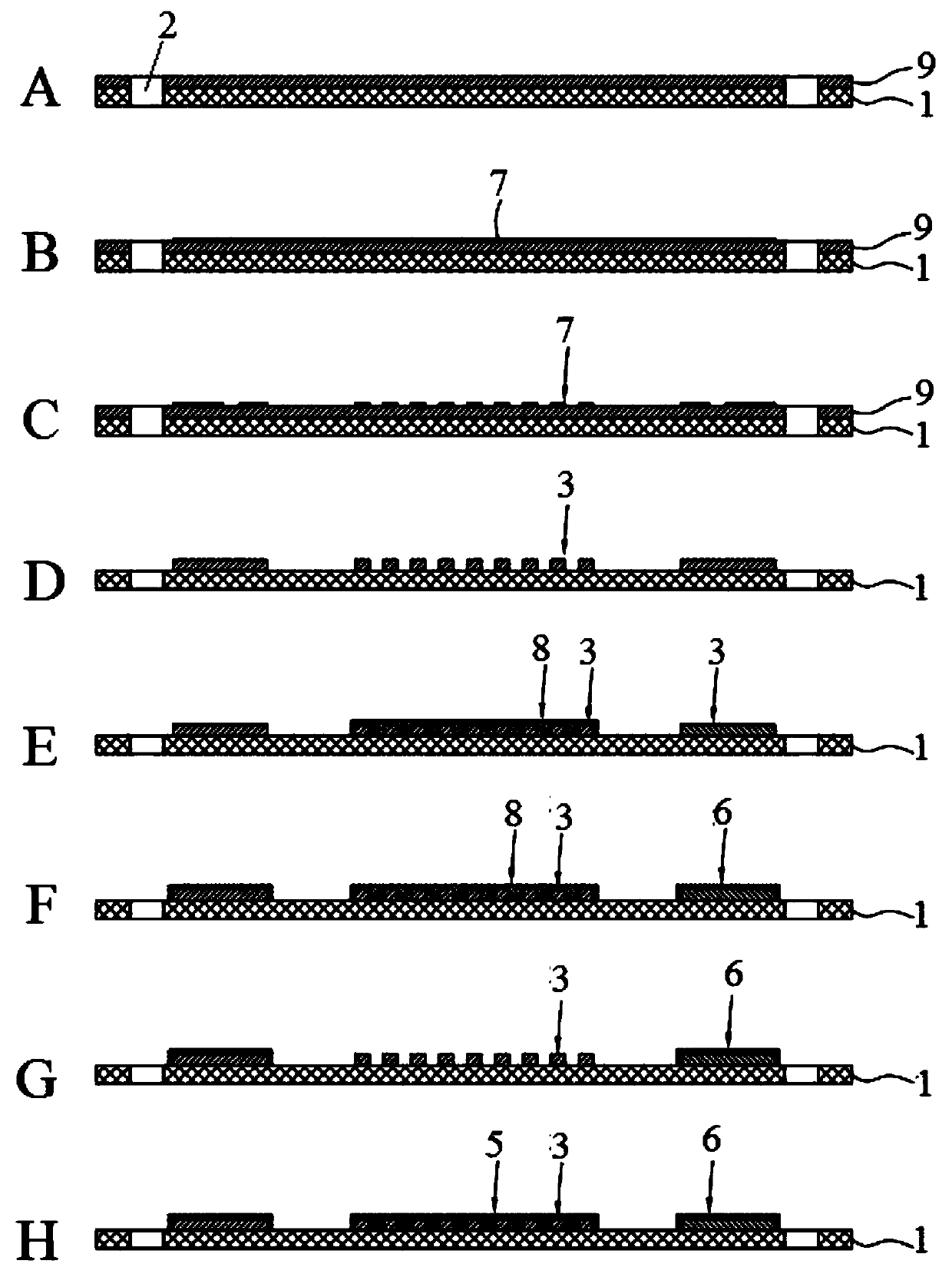

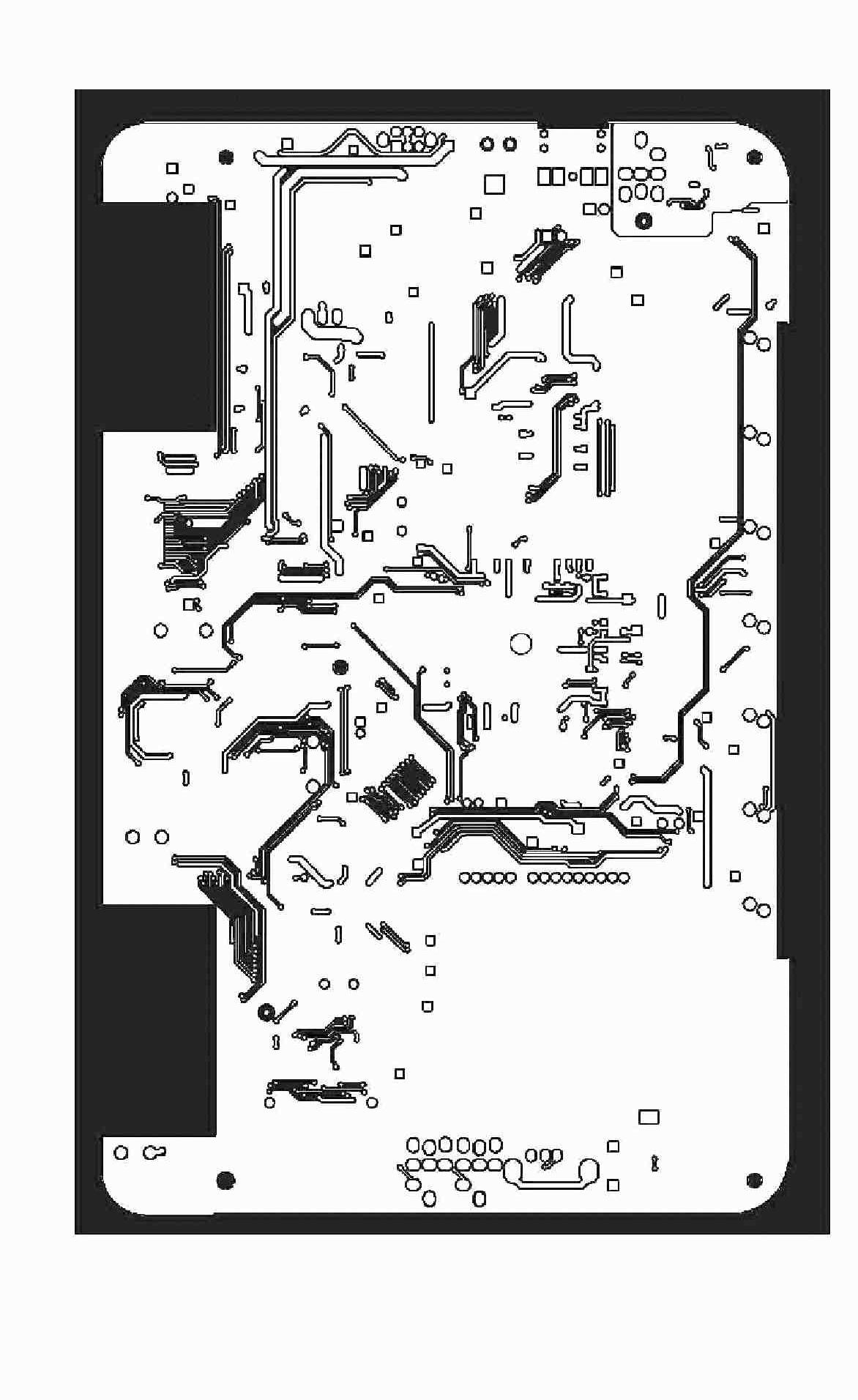

Making method of electric nickel and golden circuit board for saving nickel and gold dosage

InactiveCN101267713AOvercoming major deficienciesReduce dosageConductive material chemical/electrolytical removalCopper platingSecondary circuit

A manufacturing method of an electrolytic nickel and gold wiring board capable of saving dosage of nickel and gold, comprises broaching, copper precipitation, and copperizing on a copper-coated plate. The method is characterized by further comprising: a, adhering a dry film or printing a wet film on the wiring board, then adhering a positive sheet, exposing and developing to form a primary circuit; b, electroplating nickel and gold on all positions to be welded and copper surfaces of metal holes, then stripping; c, printing a wet film or adhering a dry film, then adhering a negative sheet, exposing and developing to form a secondary circuit; d, etching a circuit diagram, removing non-circuit portions, holding circuit portions, then performing stripping and etching detection; e, performing deoxidation treatment to the wiring board to remove oxides on the copper surfaces; f, after deoxidation treatment, resistance welding, exposing, developing, printing element symbols and machining shapes so as to manufacture the electrolytic nickel and gold wiring board only at the positions to be welded and the metal hole positions. With the method, the area of the nickel and gold can be reduced by 40-60%, thereby saving the noble metal nickel and gold and effectively reducing enterprise production cost.

Owner:陈国富

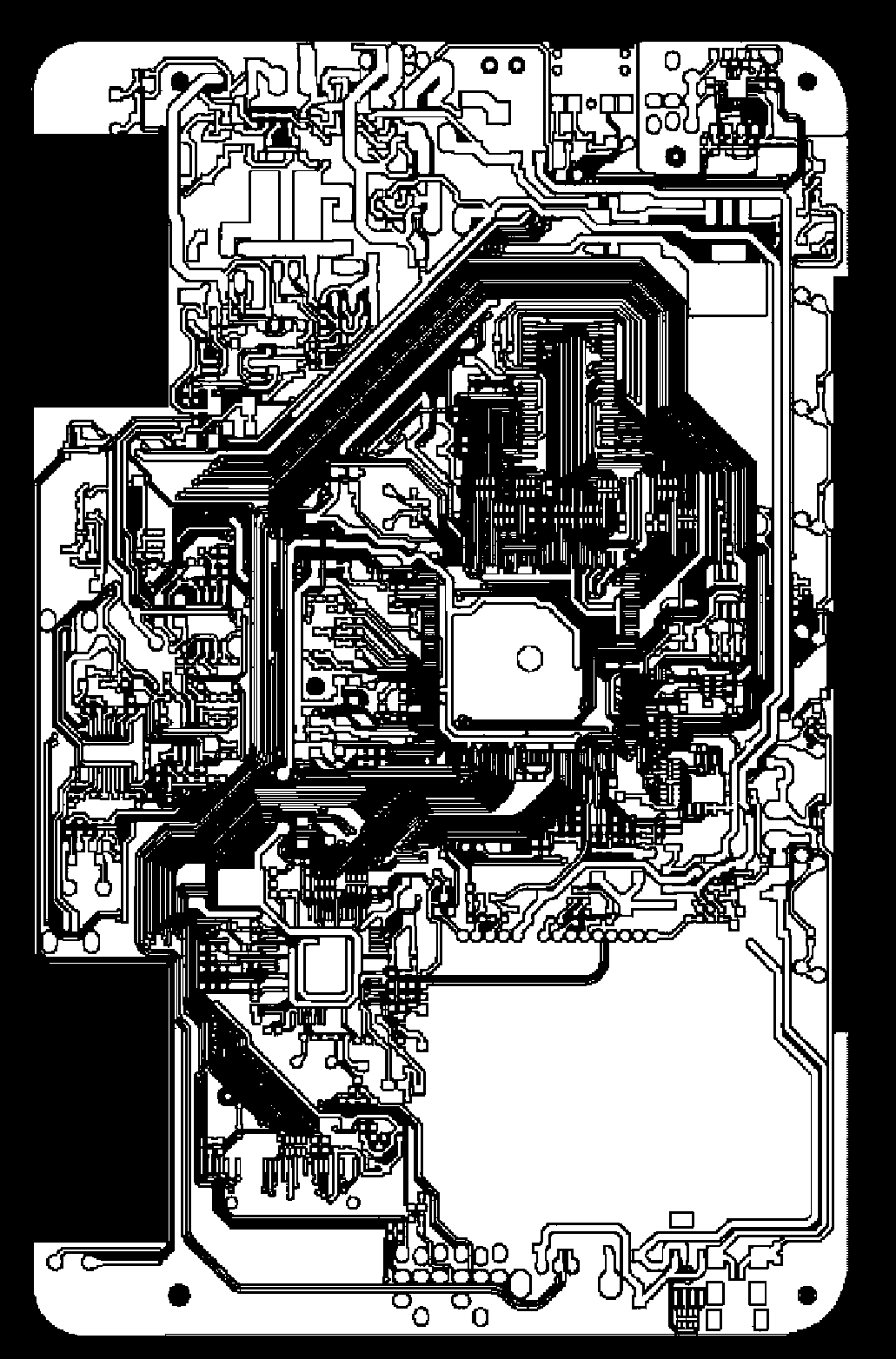

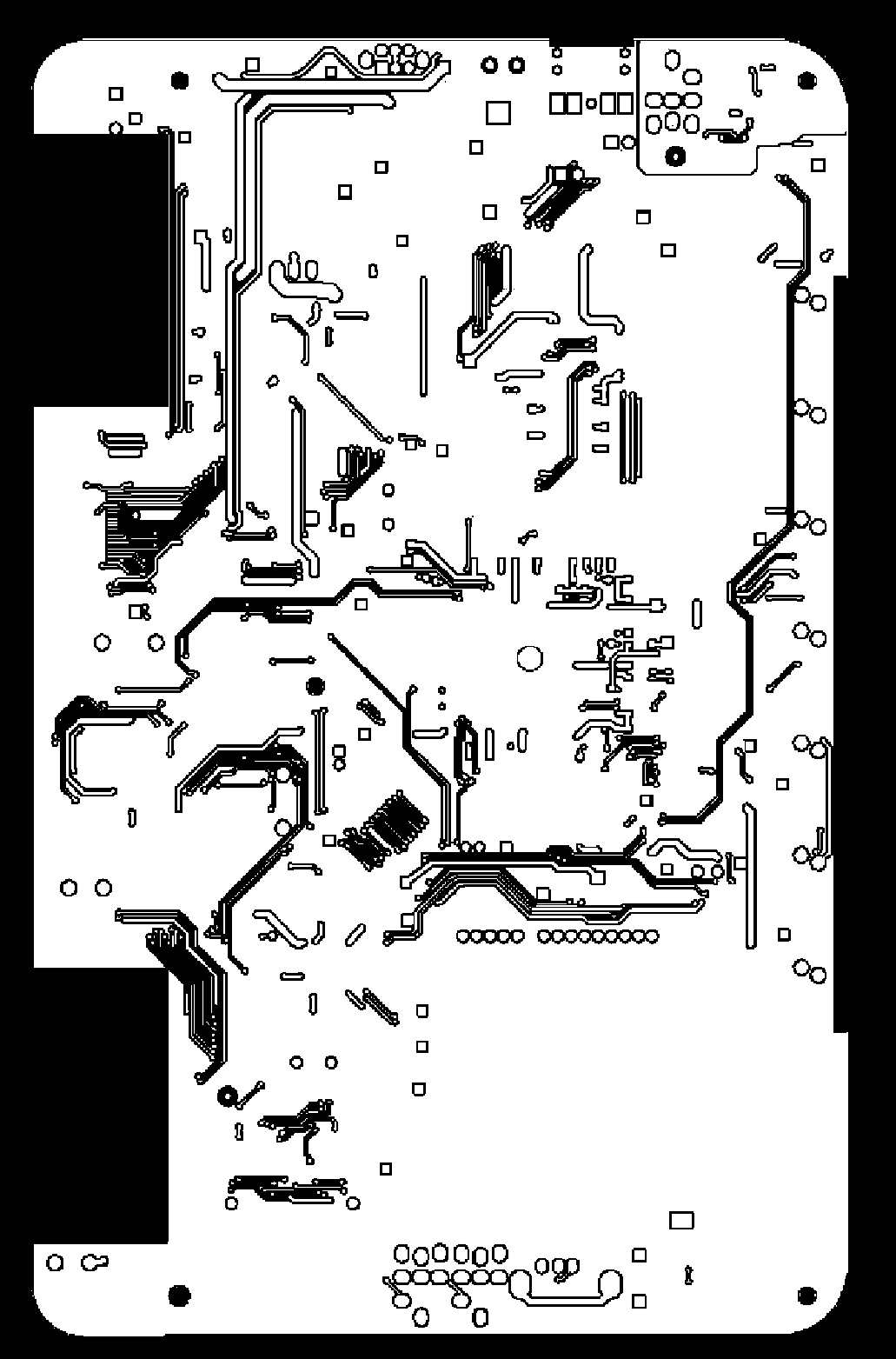

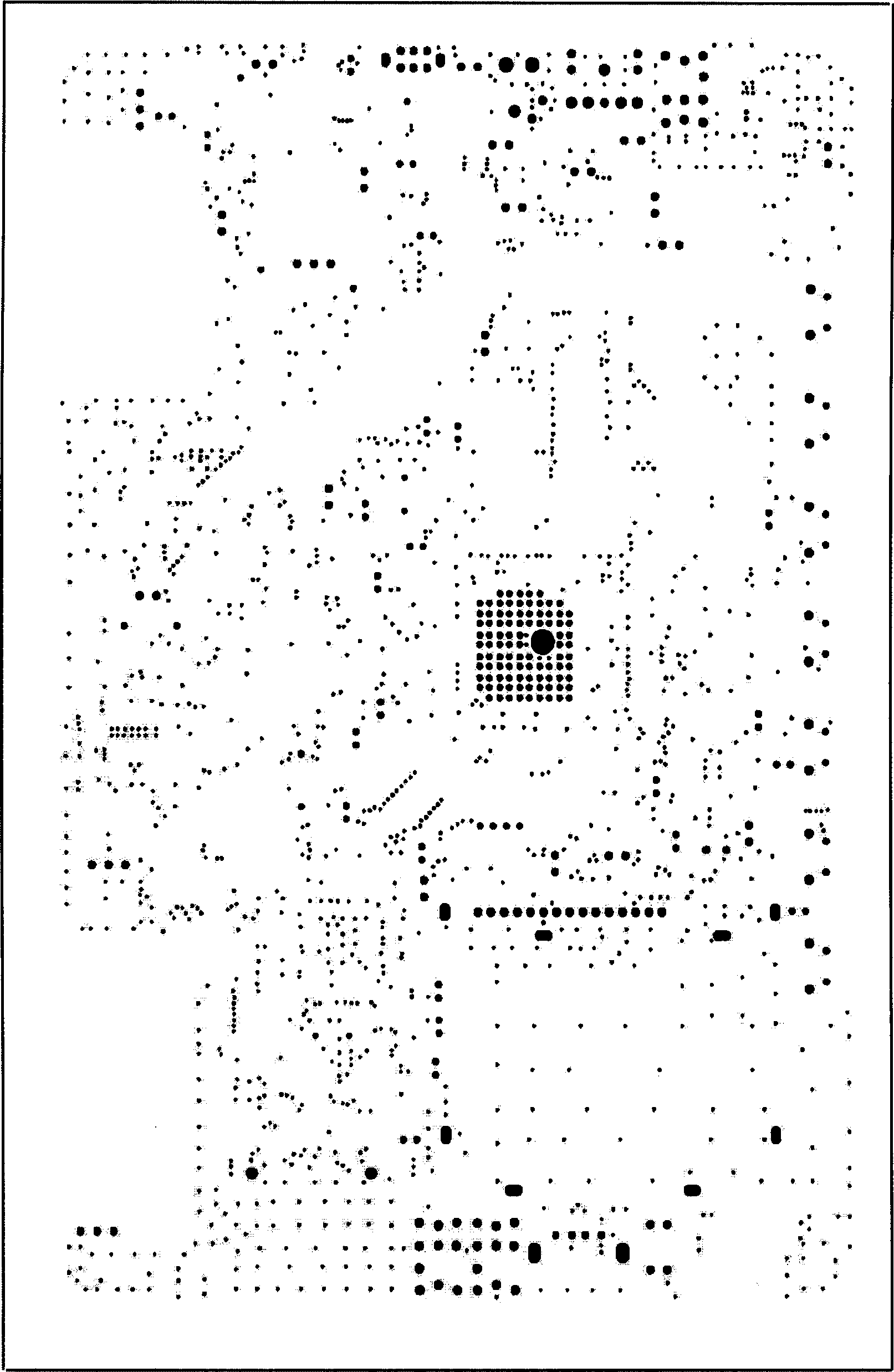

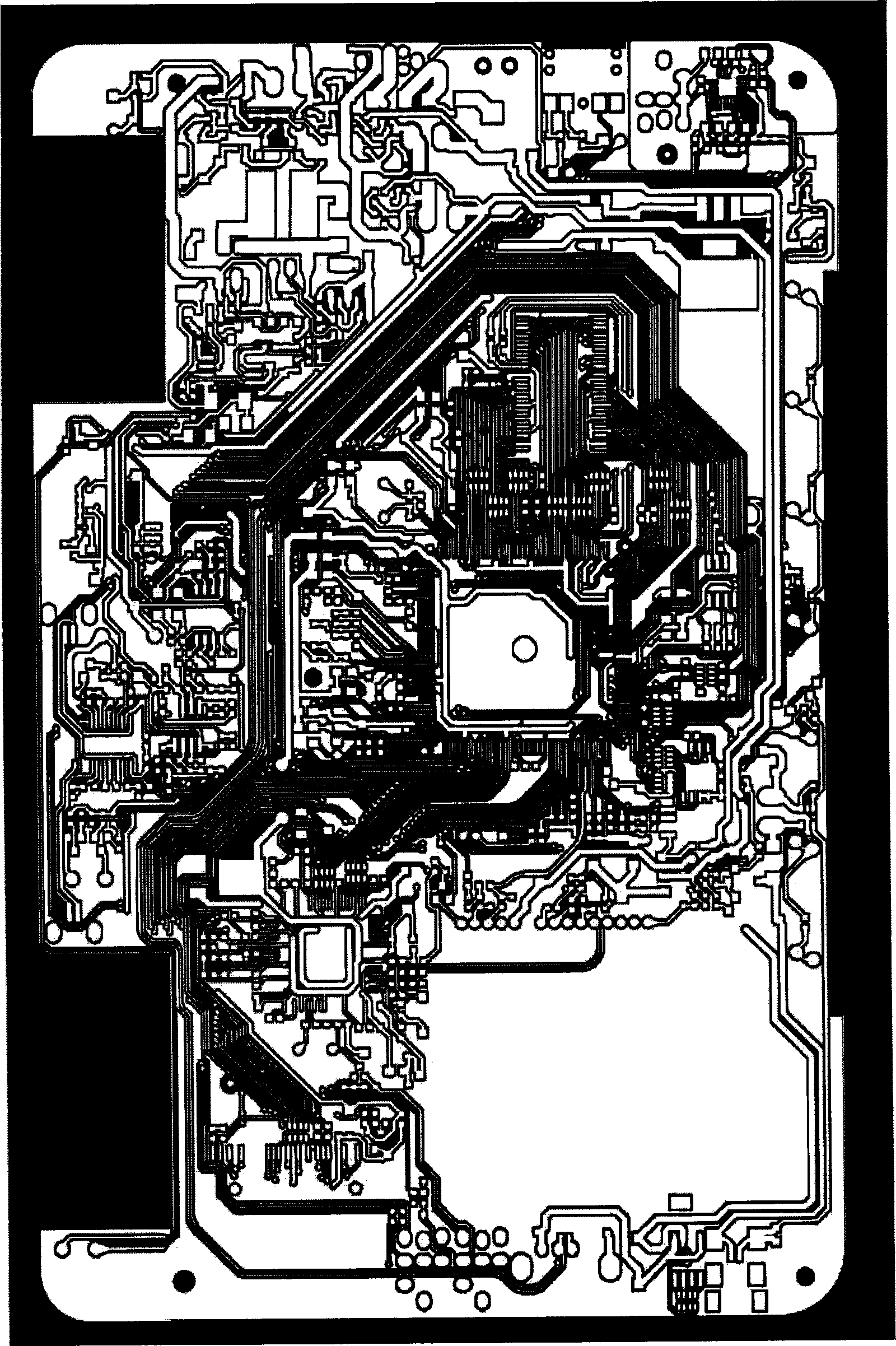

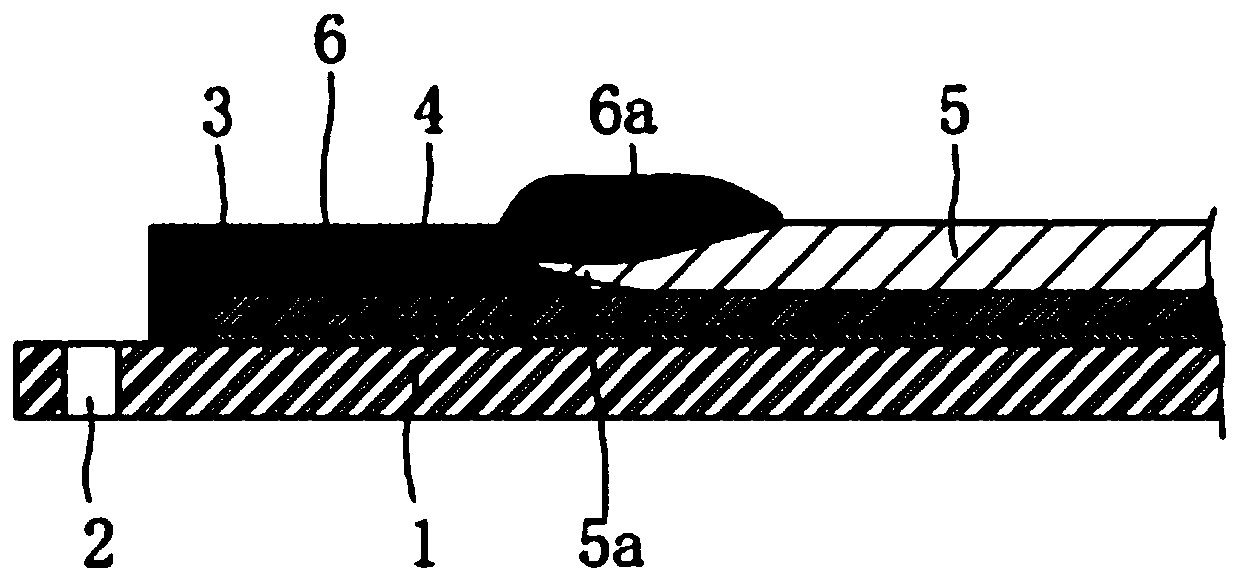

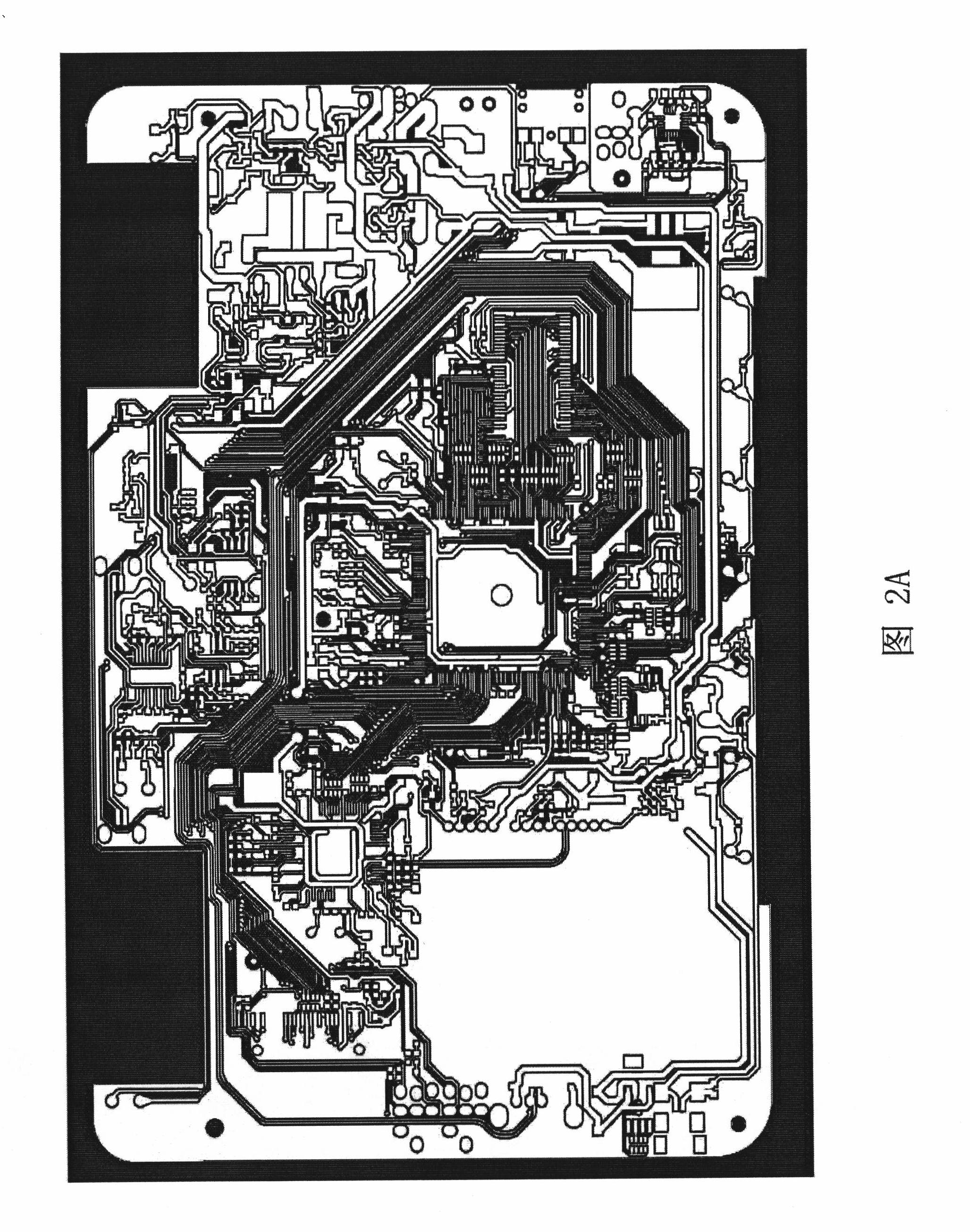

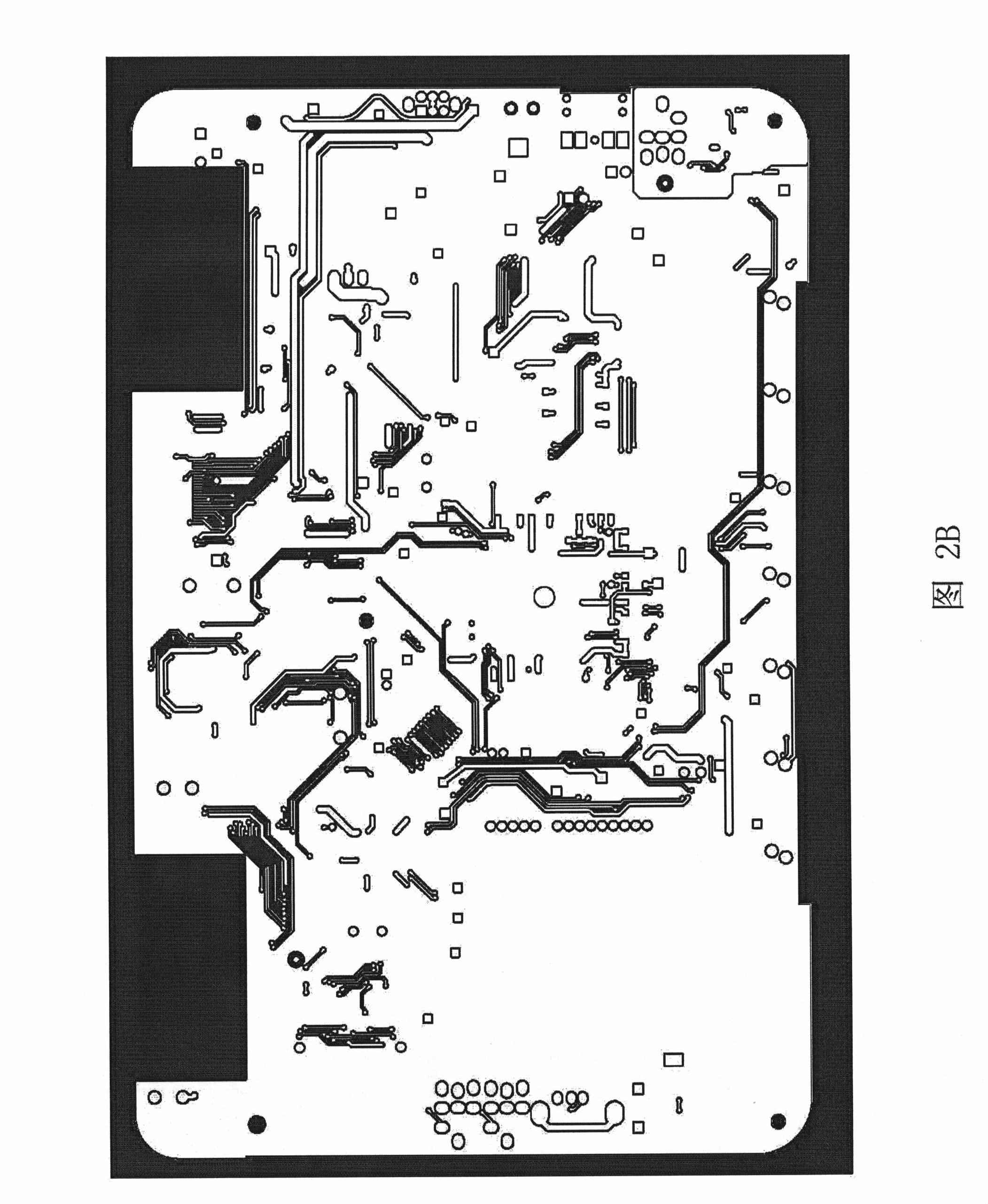

Manufacturing method of circuit board with selectively plated copper and tin

InactiveCN101521991AReduce plating areaReduce pollutionConductive material chemical/electrolytical removalPrinted element electric connection formationElectricityOptoelectronics

The invention relates to a manufacturing method of a circuit board with selectively plated copper and tin, comprising the following steps: coating a plating-resistant cover film on a copper precipitation circuit board or a circuit board plated with copper at first time, and then bonding positive sheets of all metal holes and hole rings, which are contained in circuit diagrams, on the plating-resistant cover film to form a primary circuit after exposure and development; plating copper and tin on the hole walls of all the metal holes and the hole rings and then carrying out film de-coating; coating a corrosion-resistant cover film on the de-coated circuit board, and then bonding negative sheets of the circuit diagrams on the corrosion-resistant cover film to form a secondary circuit after exposure and development; etching the circuit diagrams and then carrying out film de-coating and tin de-coating; and manufacturing a circuit board product after welding prevention, exposure, development, element mark printing, tin spraying, anti-oxidation process or turmeric and outline process. The invention selectively plates copper and tin, thereby greatly reducing the amount of copper and tin to greatly reduce the environmental pollution from tin de-coating process, effectively saving the copper, tin, water, electricity, chemical materials, energy charges and manpower and effectively reducing the production costs for enterprises.

Owner:深圳市源基电子科技有限公司 +1

Circuit board manufacturing method without tin plating, tin retreating and capable of saving copper and nickle

InactiveCN101489355AAvoid heavy pollutionSave potionConductive material chemical/electrolytical removalTinningElectricity

A method for manufacturing circuit board which is free of tin plating and tin removing and can save the using amounts of copper and nickel comprises the following steps: a. coating plating-resistant covering film on the circuit board after copper deposition or the first time of copper plating, then adhibiting the positive film of all metal holes and hole rings in the circuit pattern on the covering film for forming a primary circuit after exposing and developing; b. electroplating copper and nickel on the hole wall and hole ring of all metal holes, then removing the covering film; c. coating etching-resistant covering film on the circuit board after film removing, adhibiting the negative film of circuit pattern on the etching-resistant covering film, and forming the secondary circuit after exposing and developing; d. etching the circuit pattern, then removing film and checking erosion; and e. forming the finished product of circuit board through executing the steps of resistance welding, exposing, developing, printing component symbol or tin spraying or executing oxidation prevention procession. The method of the invention can reduce environment pollution and realize clean production through eliminating electrotinning and tin removing technique, effectively saves metal, water, electricity and chemical material and reduces production cost of enterprise through selectively electroplating copper and nickel.

Owner:陈国富

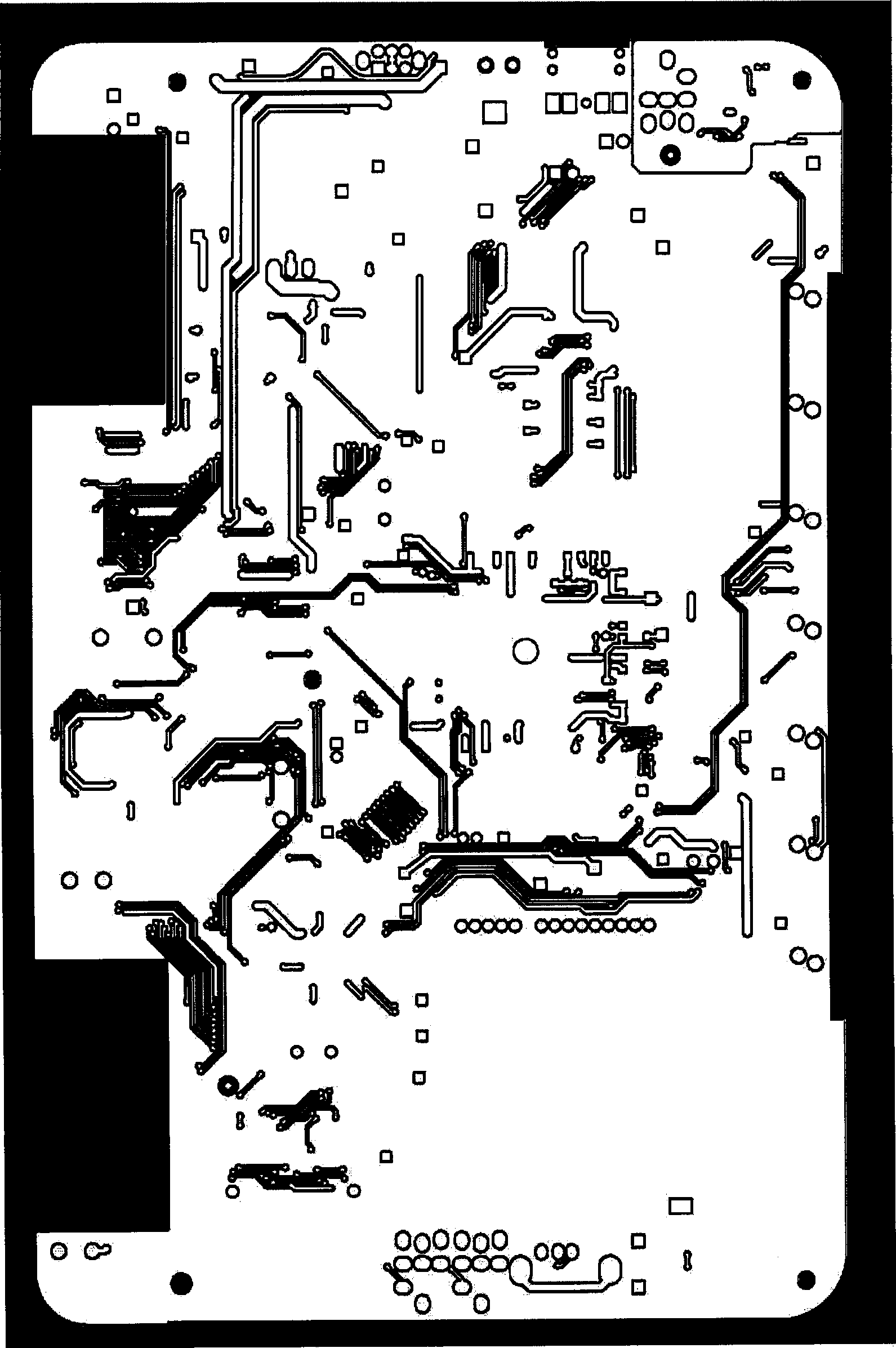

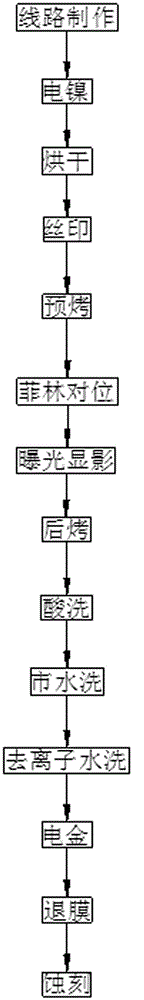

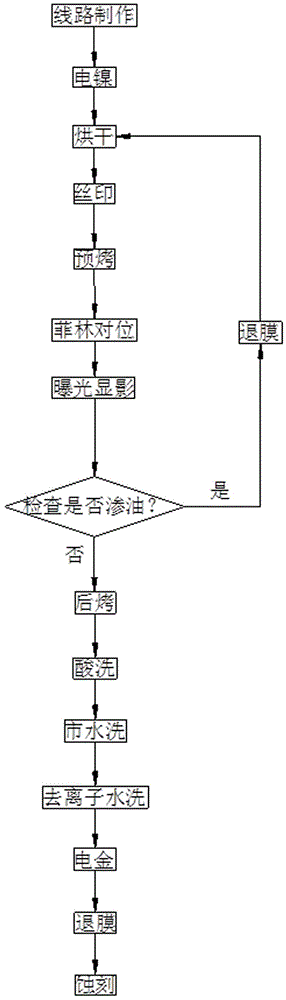

PCB electrogilding technology

InactiveCN104411107AReduce the area to be platedSave goldProcessing steps orderPrinted circuit secondary treatmentCopper platingPrinting ink

The invention discloses the PCB manufacturing technology. The PCB electrogilding technology comprises steps of, line manufacturing, a line is manufactured on a line board after copper plating; nickel plating, nickel plating is carried out in a nickel plating region of the line board; drying, the line board after nickel plating is dried; silkscreen, silkscreen for the line board is carried out by utilizing photosensitive printing ink; pre-baking, the line board after silkscreen is pre-baked; film contraposition, film contraposition for the line board is carried out; exposure development, exposure development for the film after contraposition is carried out; post-baking, post-baking for the line board after exposure development is carried out; acid pickling, acid pickling for the line board after post-baking is carried out; qualified-city-water washing, qualified-city-water washing for the line board after acid pickling is carried out; deionized water washing, deionized water washing for the line board after qualified-city-water washing is carried out; electrogilding, electrogilding for the nickel plating region of the line board is carried out; film removing, film removing for the line board after electrogilding is carried out; and etching, etching for the line board after film removing is carried out. The PCB electrogilding technology saves gold and greatly reduces production cost of enterprises.

Owner:深圳恒宝士线路板有限公司

Two-color electroplating process

InactiveCN107557830AReduce plating areaLow costLiquid/solution decomposition chemical coatingSuperimposed coating processElectroless nickelPass rate

The invention relates to a two-color electroplating process, and belongs to the technical field of water electroplating processes. The two-color electroplating process is characterized in that a two-color injection-molded to-be-treated part is taken to pre-treat, wherein pre-treatment specifically comprises the steps of hot-dipping and oil-removal, roughening, reducing, pre-impregnating, palladiumactivating and chemical nickel plating; the to-be-treated part is subjected to post-treatment, wherein the post-treatment adopts a hexavalent chromium light electroplating process or a hexavalent chromium pearl nickel electroplating process; and finally, a product subjected to the two-color electroplating process is obtained. The product is less in electroplating area and saves cost. A workpiecematched part is not electroplated and hardly affect matching precision. The manufactured part is beautiful, and the product yield is high.

Owner:江阴市羽项汽车饰件有限公司

Electroplating process of circuit board of burning-resistant board

The invention discloses an electroplating process of a circuit board of a burning-resisting board. The electroplating process comprises the following steps: firstly, providing a base plate and coating a copper foil layer at the periphery of the plate surface of the base plate; and then, carrying out boring, first-time plate grinding, copper electroplating, second-time plate grinding, outer circuit manufacturing, and electroplating, wherein the copper foil layer is of a latticed structure; the current density is 15-20ASF during the electroplating process, and the electroplating time is 90-100 minutes. The copper foil layer is arranged at the periphery of the plate surface of the base plate, so that the electroplating is uniform without a plate burning phenomenon; a low-current density long-time electroplating way is adopted to ensure the uniform and stable current of the plate surface, so that the plate is not burnt due to excessive current, the binding force and structural cohesive force of the based copper and electroplated copper of the plate are kept, and the quality of the circuit board is ensured. Moreover, the latticed structure is arranged at the periphery of the plate surface for saving the copper, so that the electroplating area is reduced during the electroplating process, and the copper is further saved.

Owner:SHENZHEN XINGDA PCB

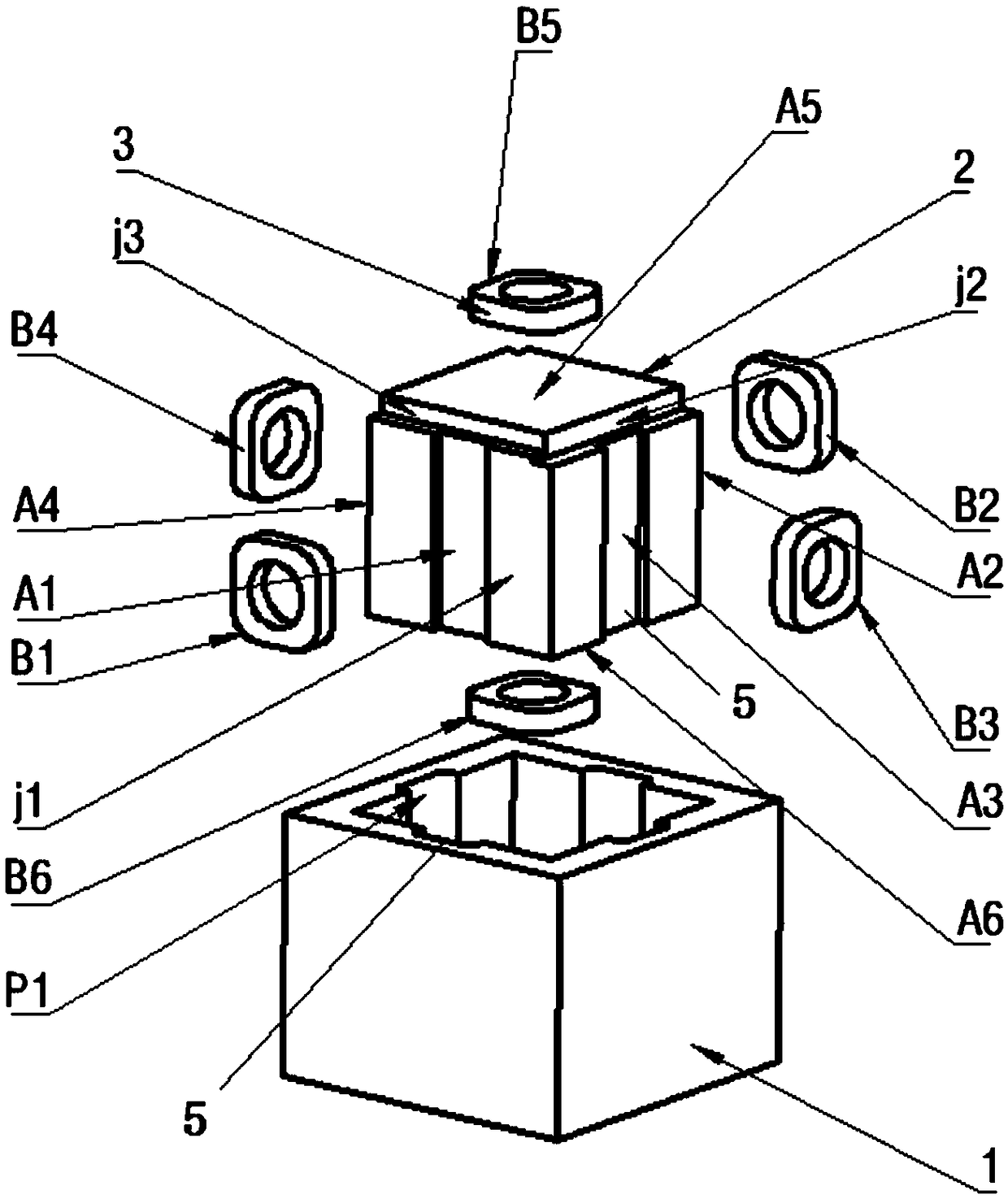

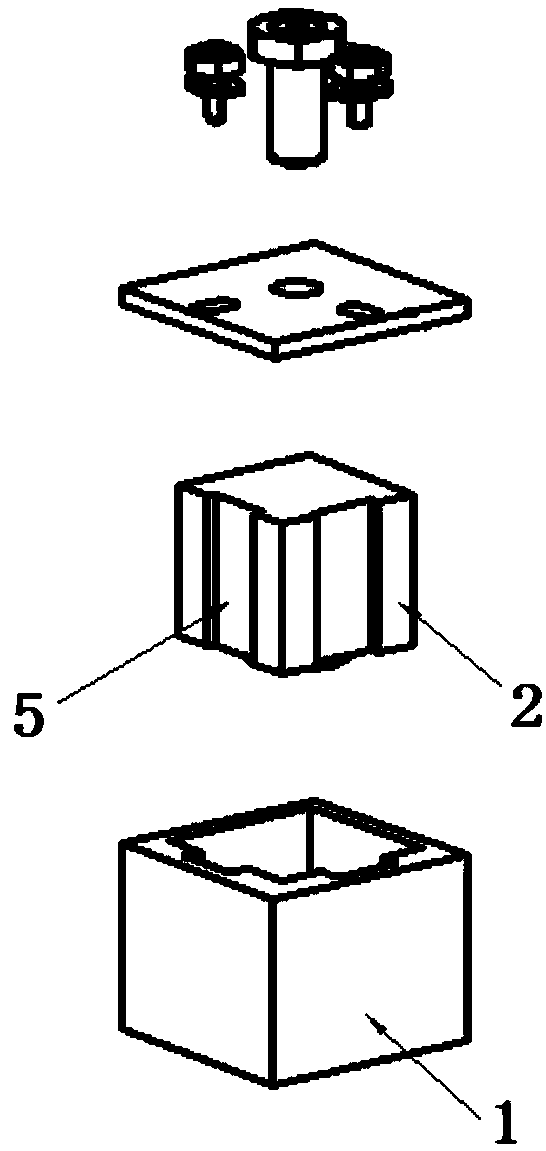

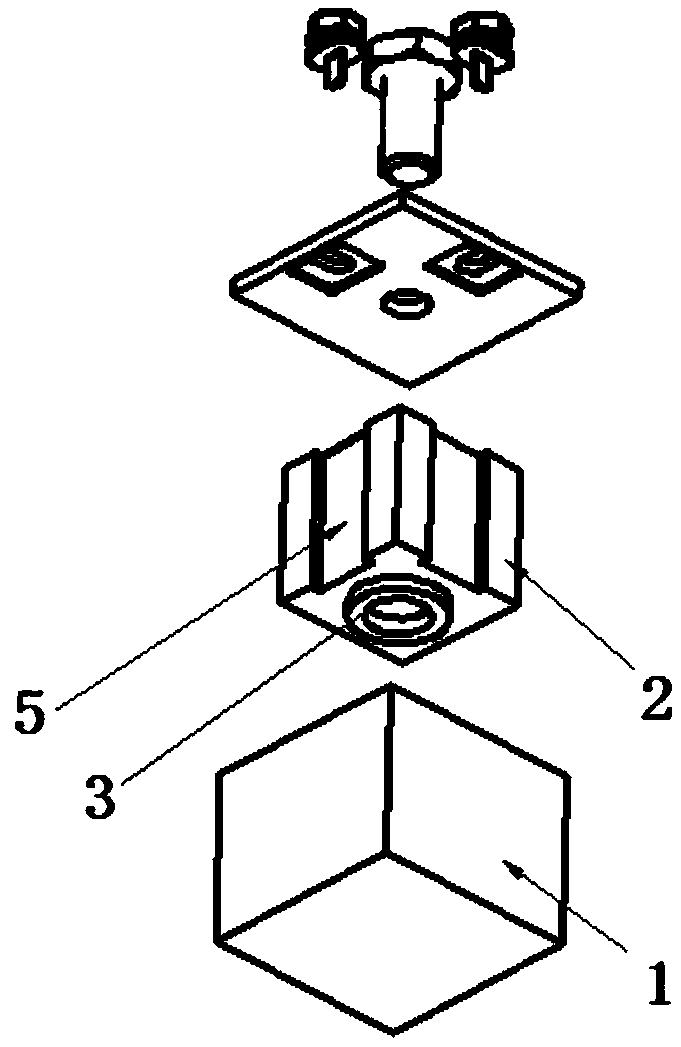

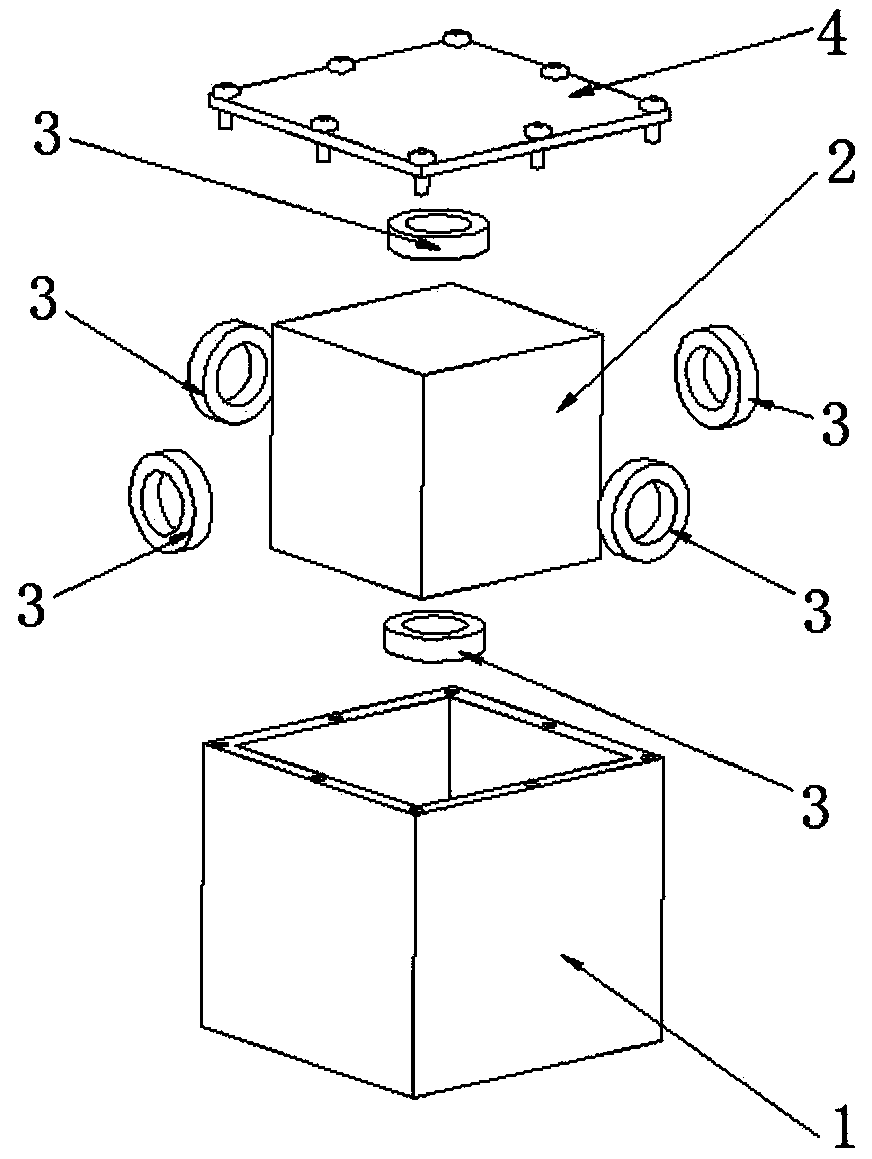

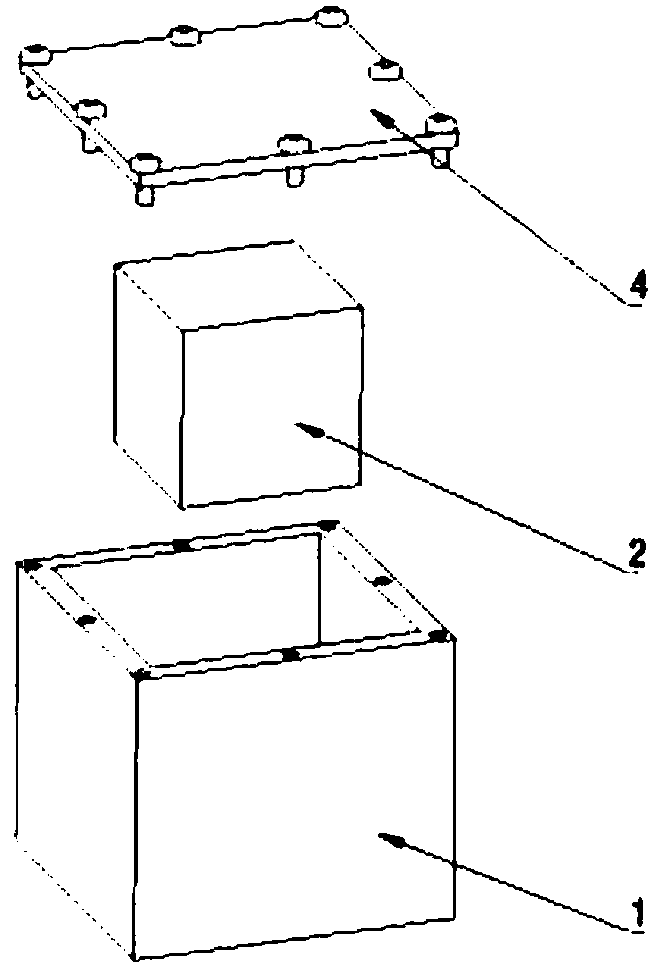

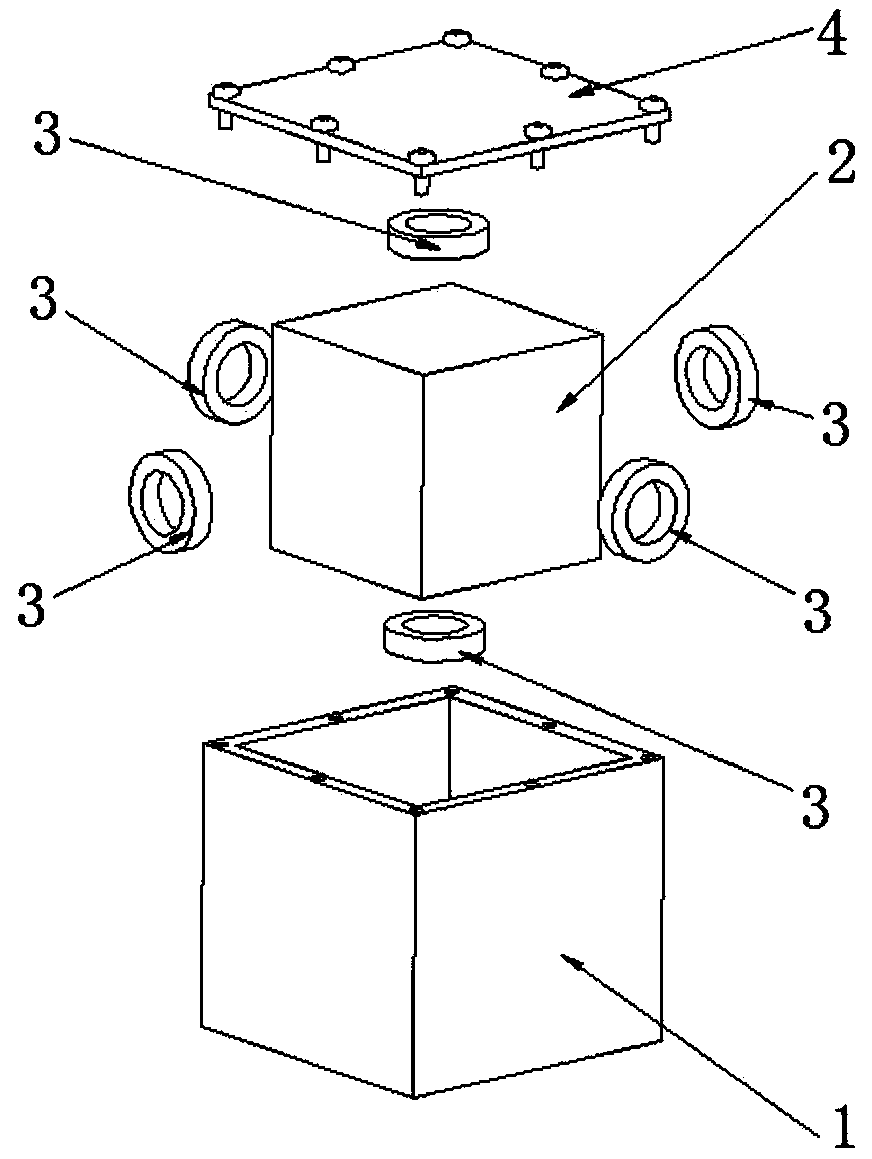

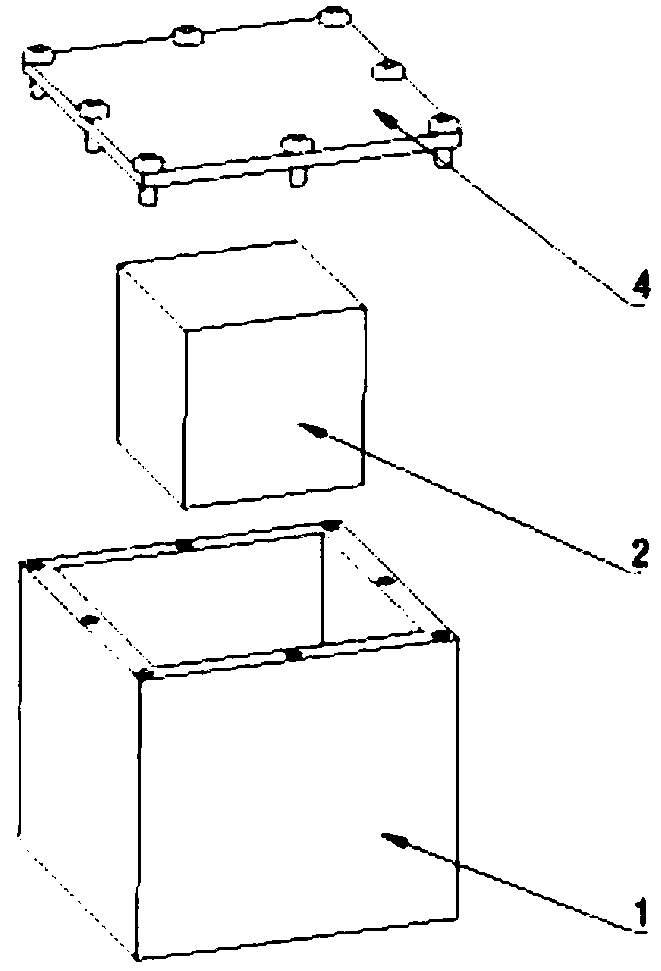

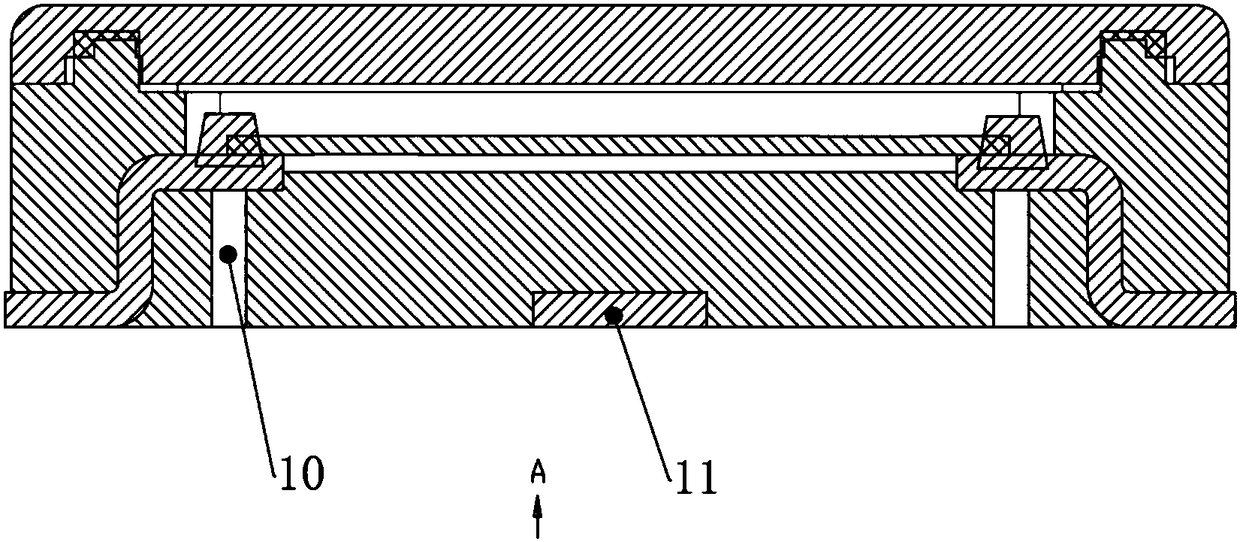

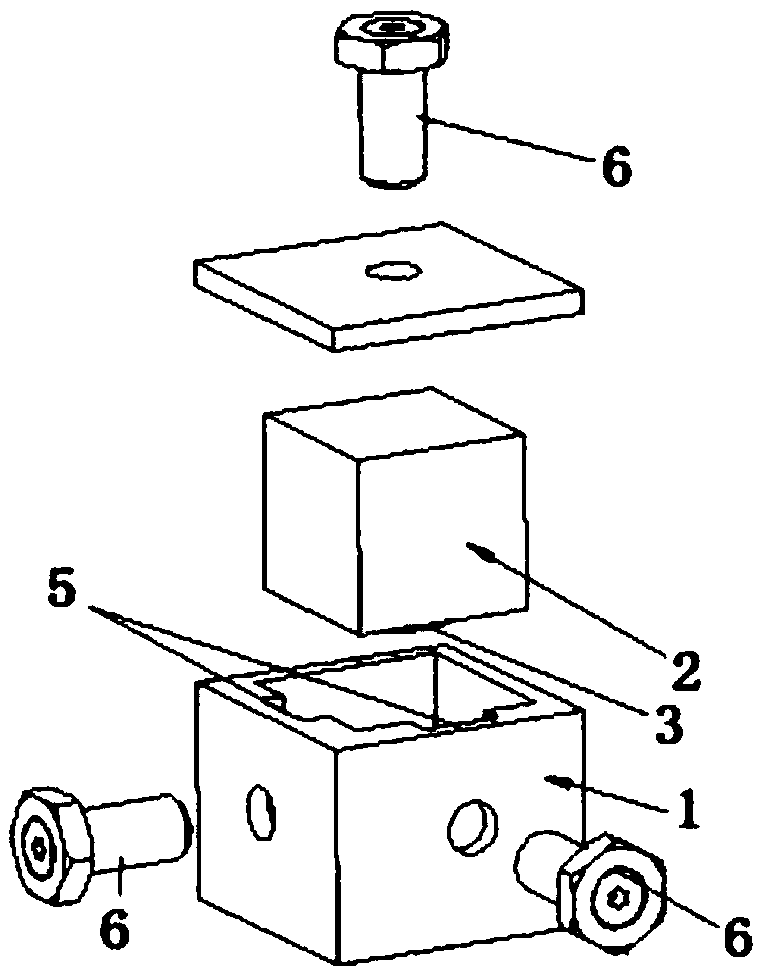

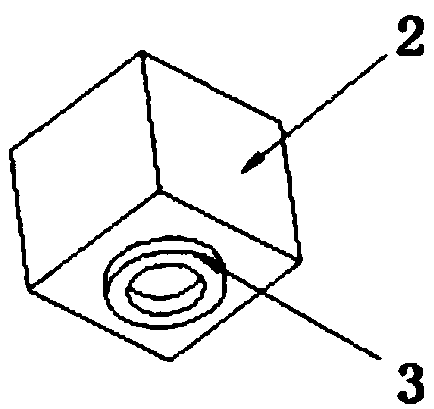

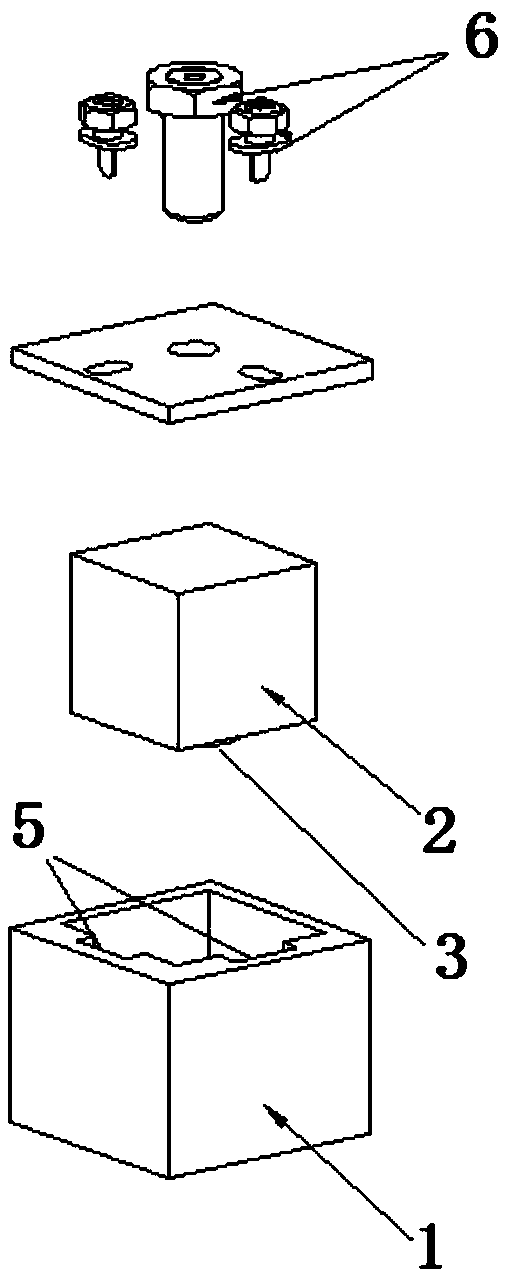

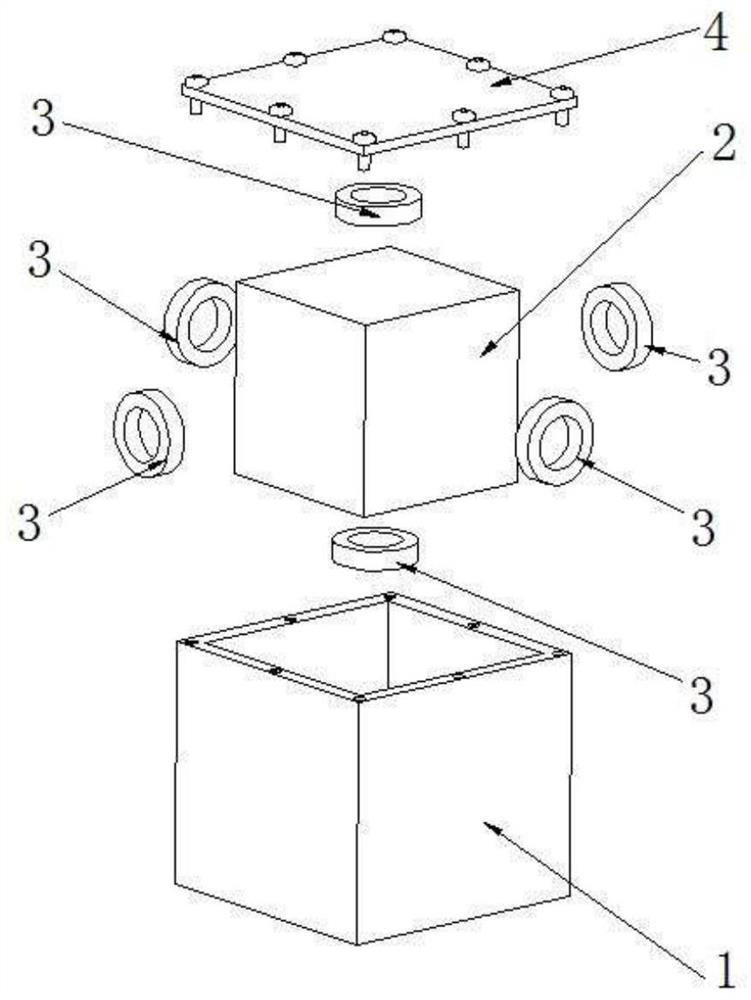

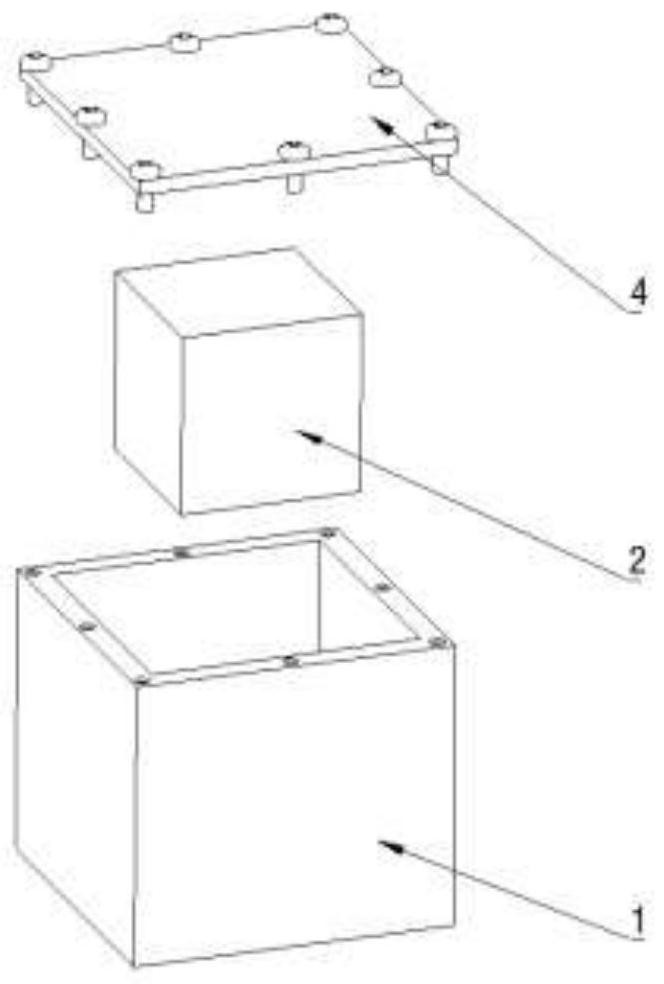

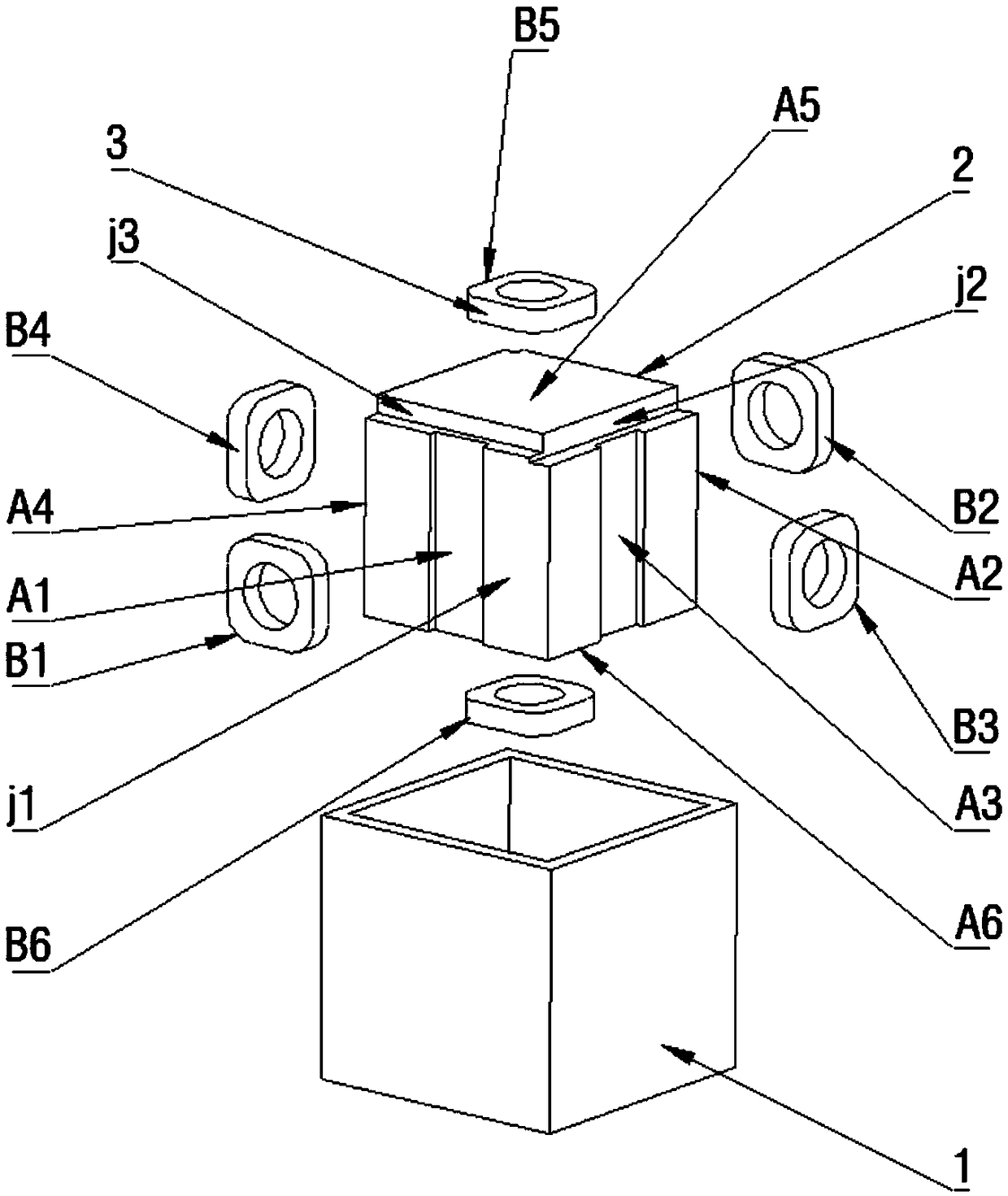

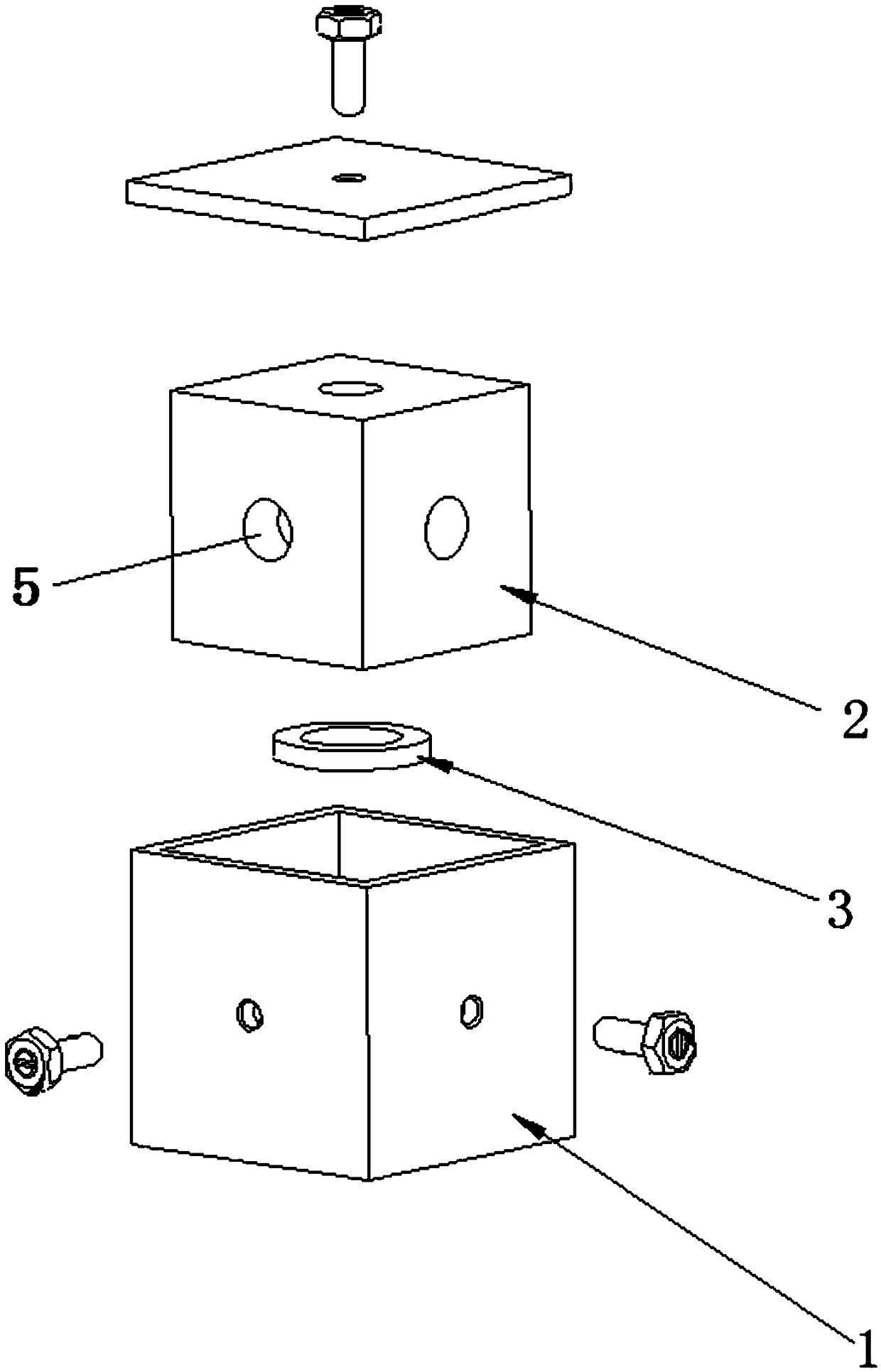

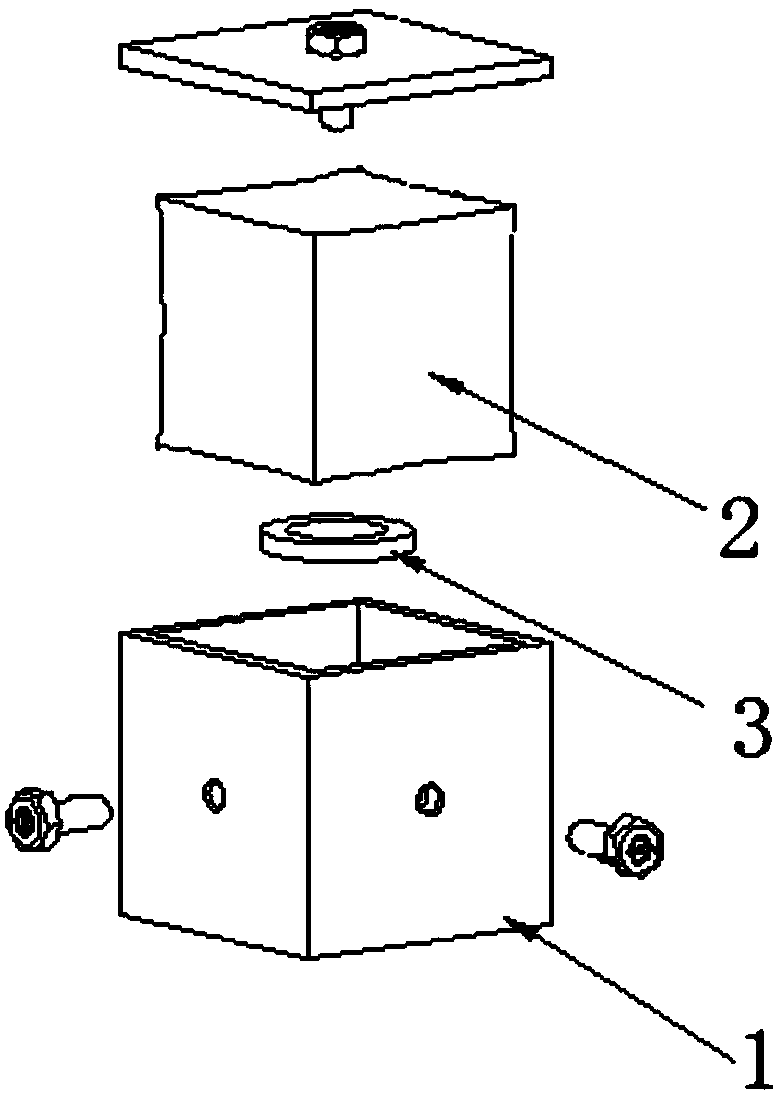

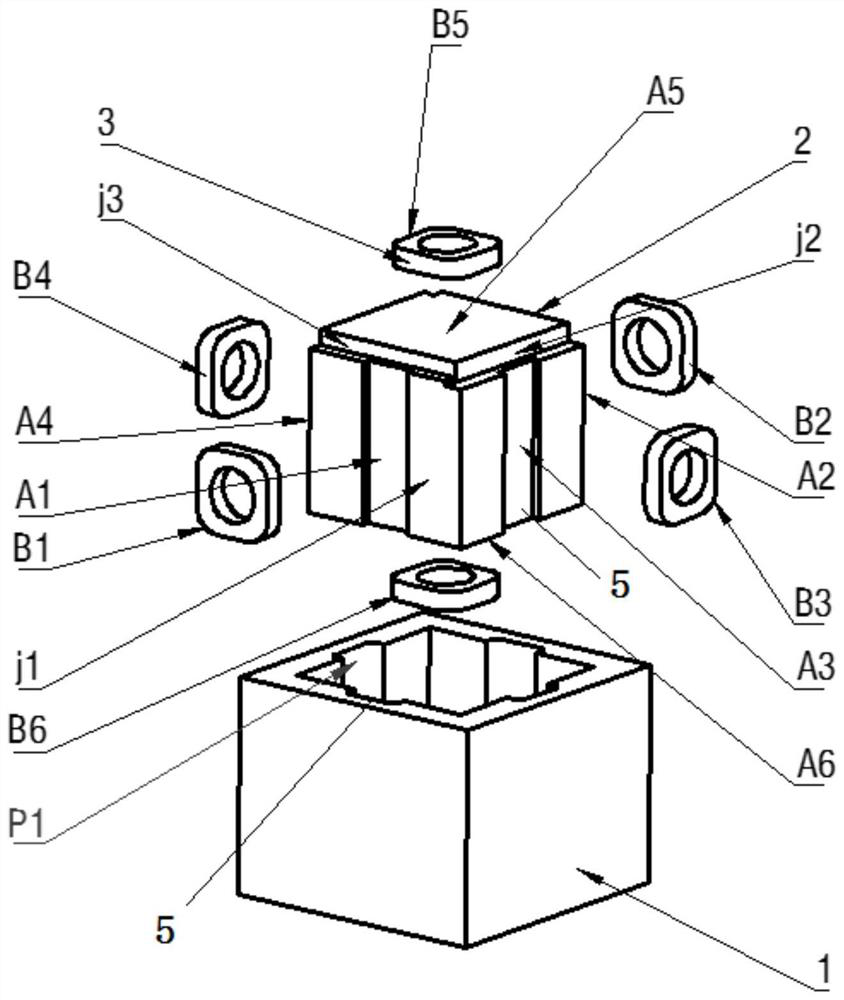

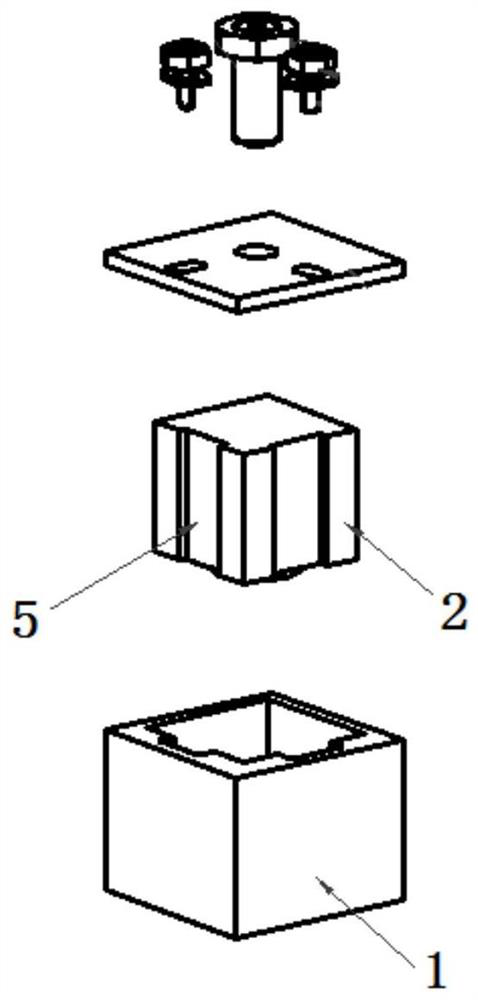

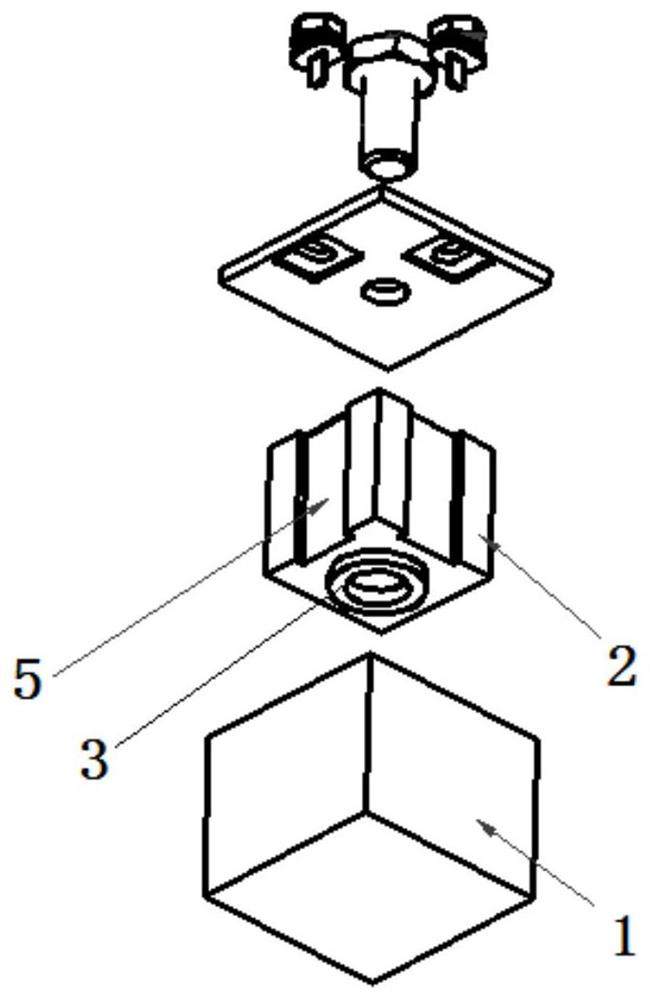

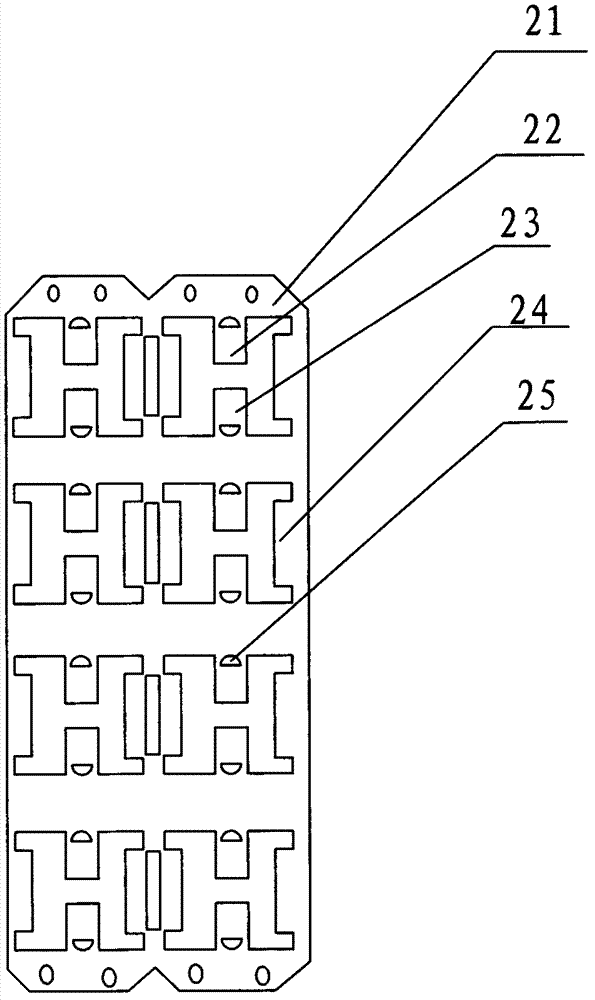

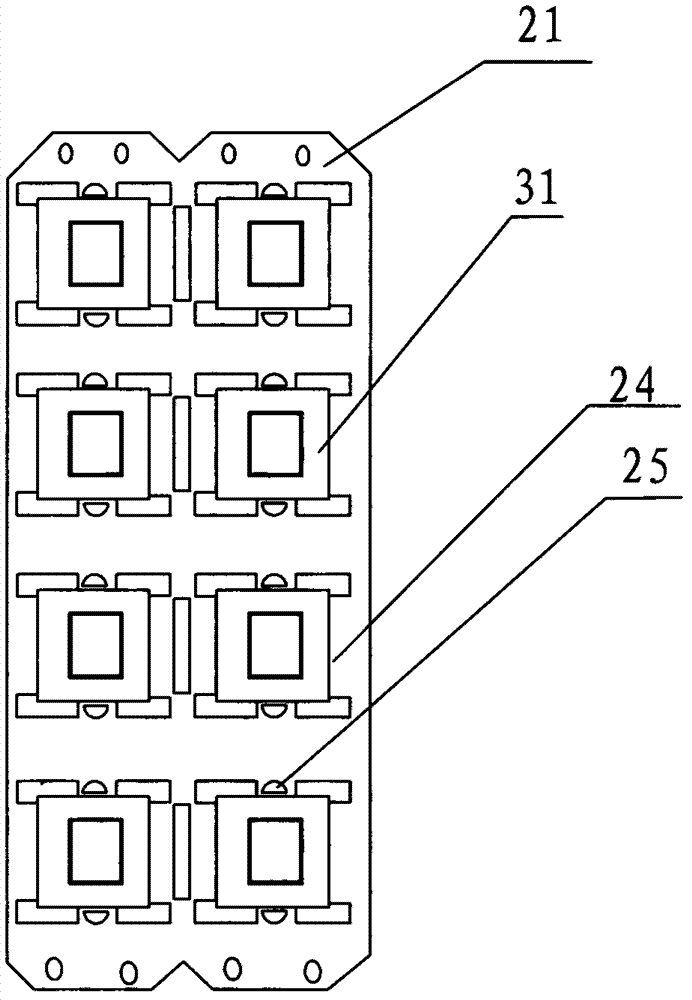

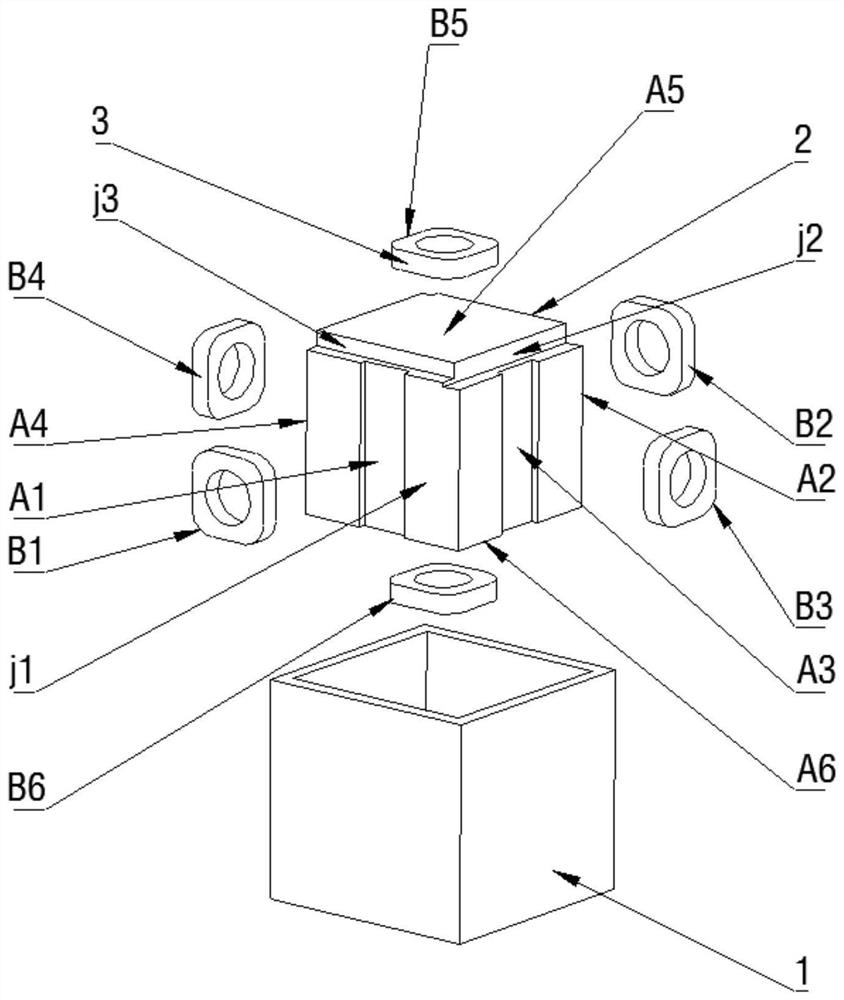

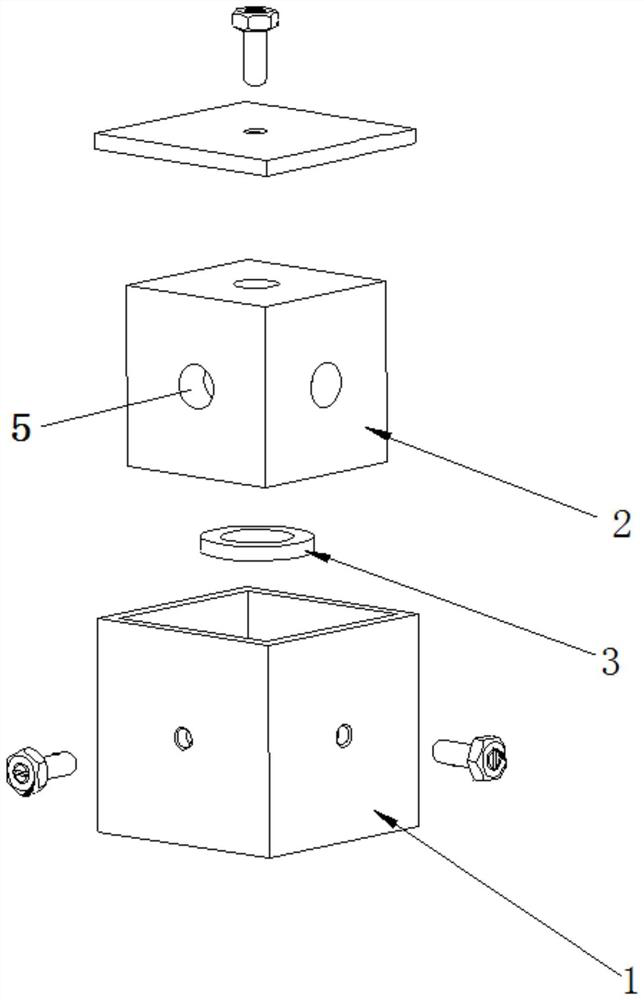

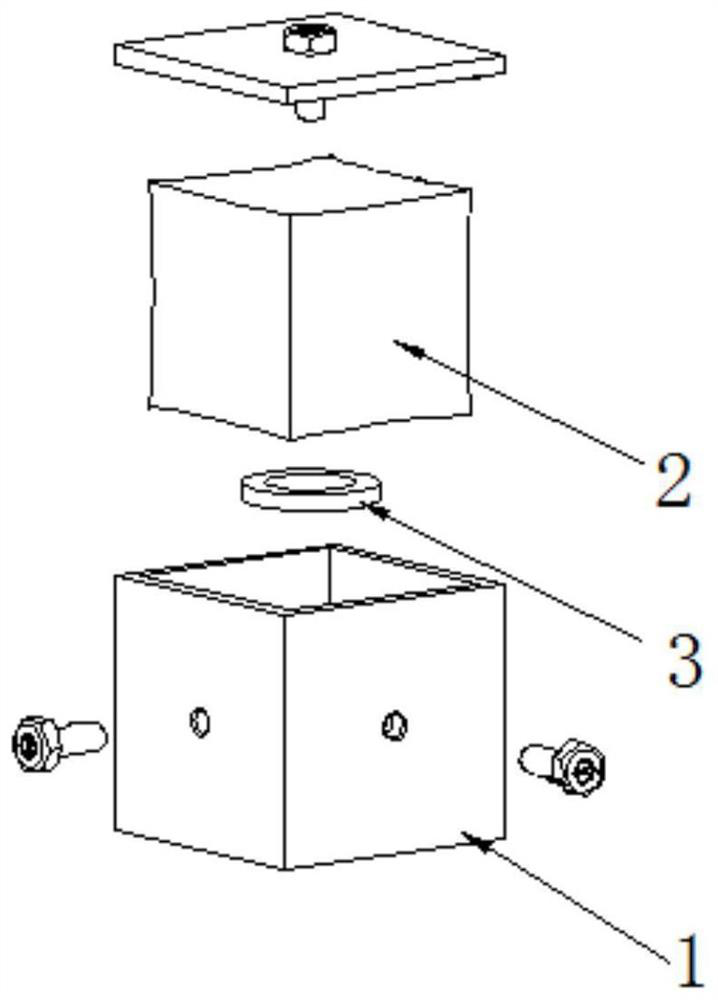

Special-shaped cavity tri-mode resonant structure and filter containing the same

The patent for invention discloses a special-shaped cavity tri-mode resonant structure and a filter containing the same. The special-shaped cavity tri-mode resonant structure comprises a cavity and acover plate. A medium resonant block and a medium support frame are arranged in the cavity; at least one end surface of the cavity is concave or convex, and at least one end surface of the medium resonant block is convex or concave; the medium resonant block and the medium support frame form a tri-mode medium resonant rod; one end or any end of a similar cubic medium resonant block is respectivelyconnected with the medium support frame; the medium support frame is connected with the inner wall of the cavity; and the medium resonant block forms tri-mode resonance in three directions of an X axis, a Y axis and a Z axis of the cavity. The cavity filter in the invention is used so that a high Q value is ensured to be obtained under a small distance between the resonant rod and the cavity; meanwhile, the tuning range of a tuning screw rod is enlarged, the sensitiveness of the small distance between the cavity and the medium resonant block to the resonant frequency is reduced, production and debugging are facilitated, and the production cost is reduced.

Owner:HONGKONG FINGU DEV CO LTD

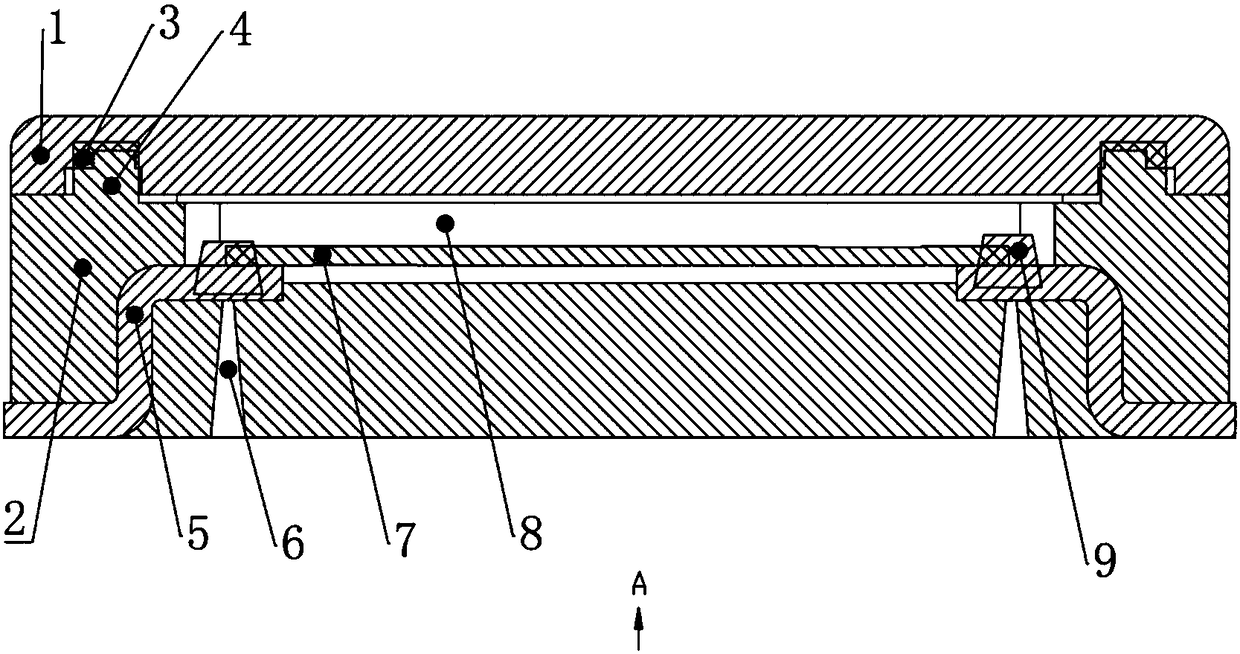

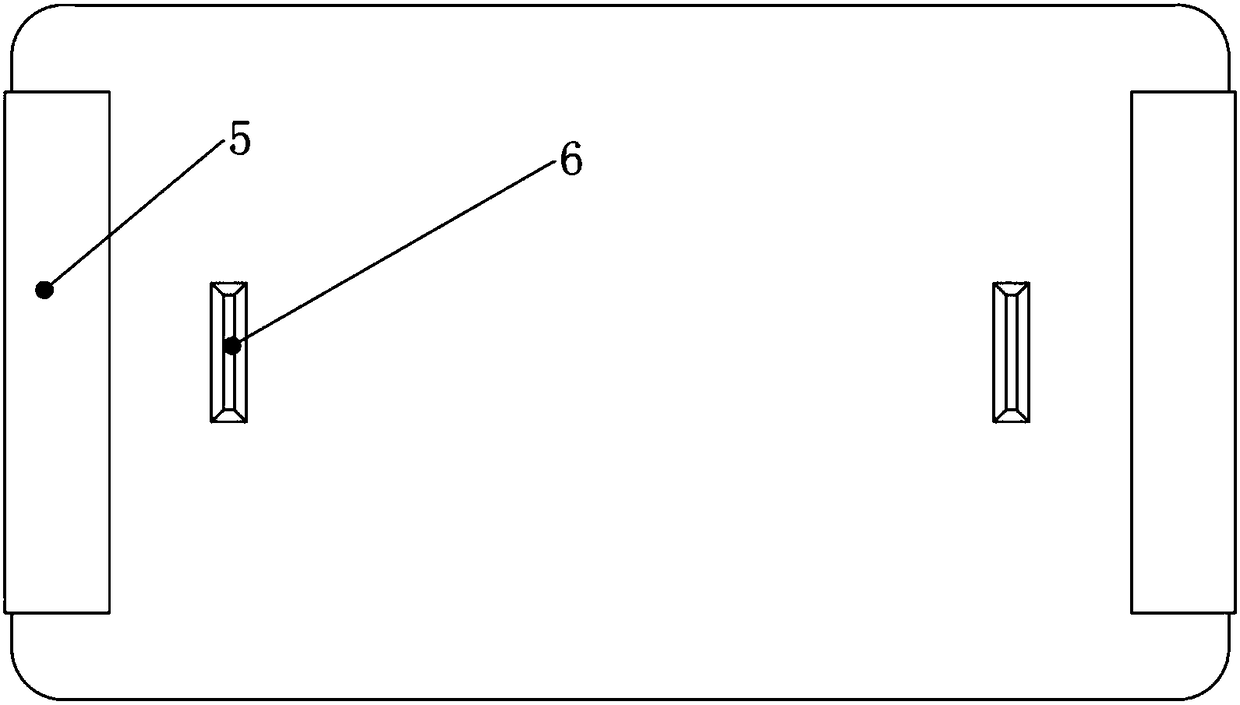

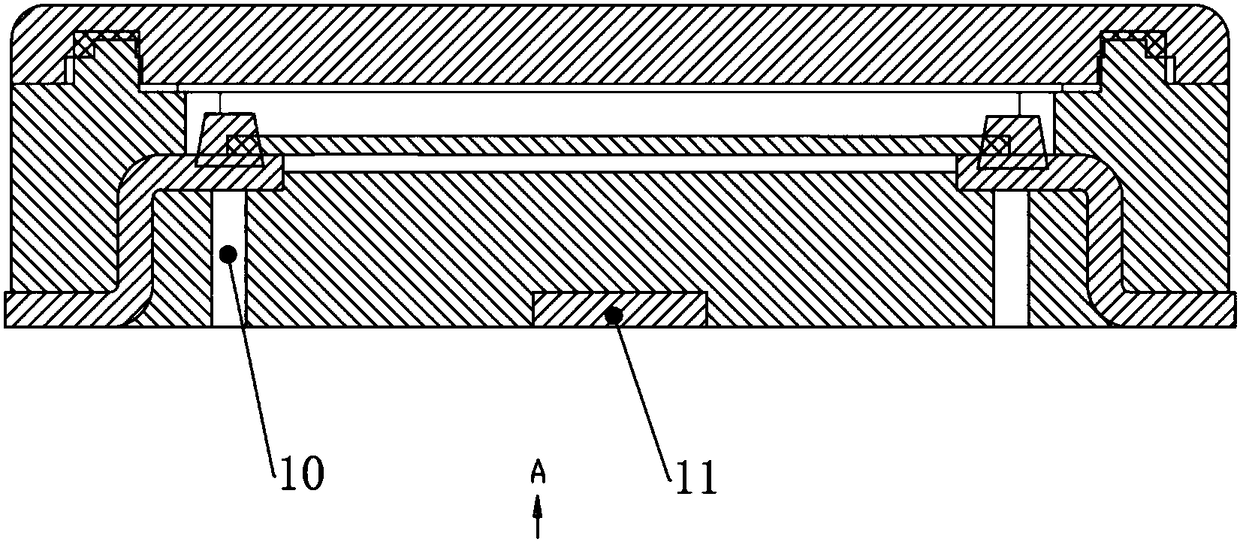

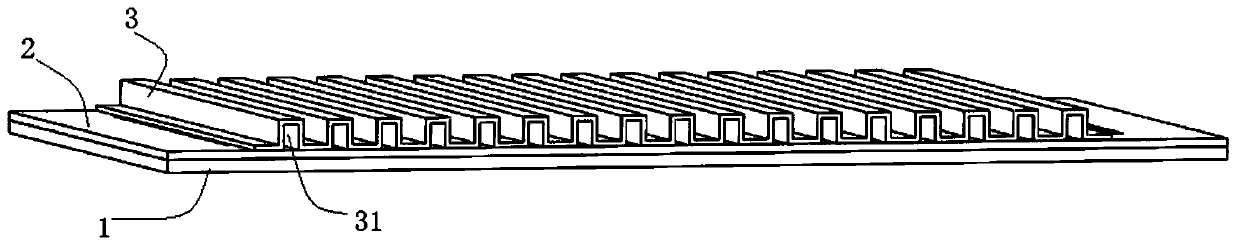

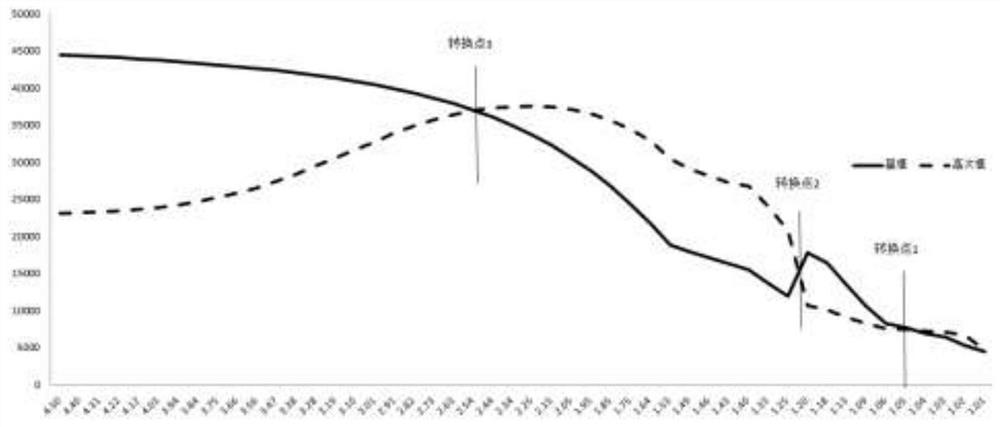

Cavity high-Q three-mode dielectric resonance structure and filter comprising resonant structure

The invention discloses a cavity high-Q three-mode dielectric resonance structure and a filter comprising the resonant structure. The dielectric resonance structure comprises a cavity and a cover plate, wherein a dielectric resonance block similar to a square shape and a dielectric support frame are arranged in the cavity; the dielectric resonance block similar to a square shape and the dielectricsupport frame are arranged in the cavity form a three-mode dielectric resonance rod; air is formed between the three-mode dielectric resonance rod and the inner wall of the cavity; one end or any oneend of the dielectric resonance block similar to a square shape is connected with the dielectric support frame separately; the dielectric support frame is connected with the inner wall of the cavity;and the dielectric resonance block similar to a square shape forms three-mode resonance in three directions of X, Y and Z axis in the cavity. Compared with the existing cavity filter, the size of thecavity filter of the invention is reduced by 40%, the insertion loss is reduced by 30% or above, and it is ensured that a high Q value can be obtained under a relatively small spacing between the resonance rod and the cavity.

Owner:HONGKONG FINGU DEV CO LTD

Cavity high-Q three-mode dielectric resonance hollow structure and filter comprising resonant structure

The invention discloses a cavity high-Q three-mode dielectric resonance hollow structure and a filter comprising the resonant structure. The dielectric resonance hollow structure comprises a cavity and a cover plate, wherein a dielectric resonance block similar to a square shape and a dielectric support frame are arranged in the cavity; the dielectric resonance block similar to a square shape andthe dielectric support frame form a three-mode dielectric resonance rod; air is formed between the three-mode dielectric resonance rod and the inner wall of the cavity; one end or any one end of the dielectric resonance block similar to a square shape is connected with the dielectric support frame separately; the dielectric support frame is connected with the inner wall of the cavity; and the dielectric resonance block similar to a square shape forms three-mode resonance in three directions of X, Y and Z axis in the cavity. Compared with the existing cavity filter, the size of the cavity filter of the invention is reduced by 40%, the insertion loss is reduced by 30% or above, and it is ensured that a high Q value can be obtained under a relatively small spacing between the resonance rod and the cavity.

Owner:HONGKONG FINGU DEV CO LTD

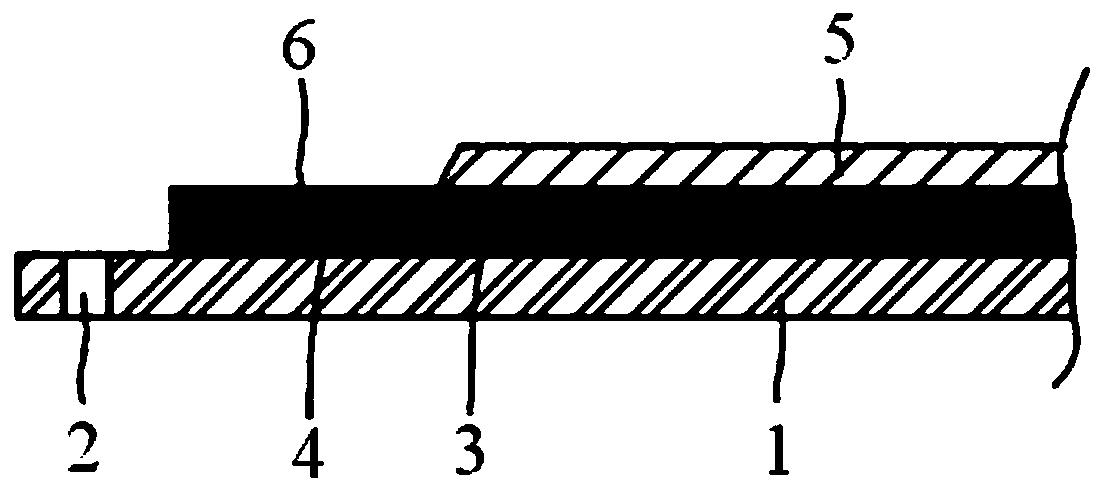

Flexible printed circuit board and manufacturing method thereof

ActiveCN110402020AAvoid it happening againAvoid erosionPrinted circuit aspectsElectrical connection printed elementsResistElectrical conductor

The invention discloses a flexible printed circuit board. The flexible printed circuit board comprises an insulation substrate, the insulation substrate is provided with a conductor layer, the insulation substrate is punched with a sprocket hole by adopting a die, and the flexible printed circuit board further comprises an electroplated tin alloy layer, a solder resist and a resist; the conductorlayer is etched to form a conductor pattern, the part in the conductor pattern except a connecting terminal is printed with the resist; the connecting terminal in the conductor pattern is provided with the electroplated tin alloy layer; and when the resist printed in the conductor pattern is peeled off, the solder resist is printed at the same position. The connecting terminal on the circuit pattern except the connecting terminal is printed with the layer of solder resist, then the connecting terminal in the conductor pattern is provided with the electroplated tin alloy layer, and after the resist is peeled off, the solder resist is printed, so that there is no a tin layer at the lower portion of the solder resist to avoid the heat treatment during printing of the solder resist to diffusethe copper into the tin layer to form a fragile tin-copper alloy layer to improve the bending properties of the product.

Owner:江苏上达半导体有限公司

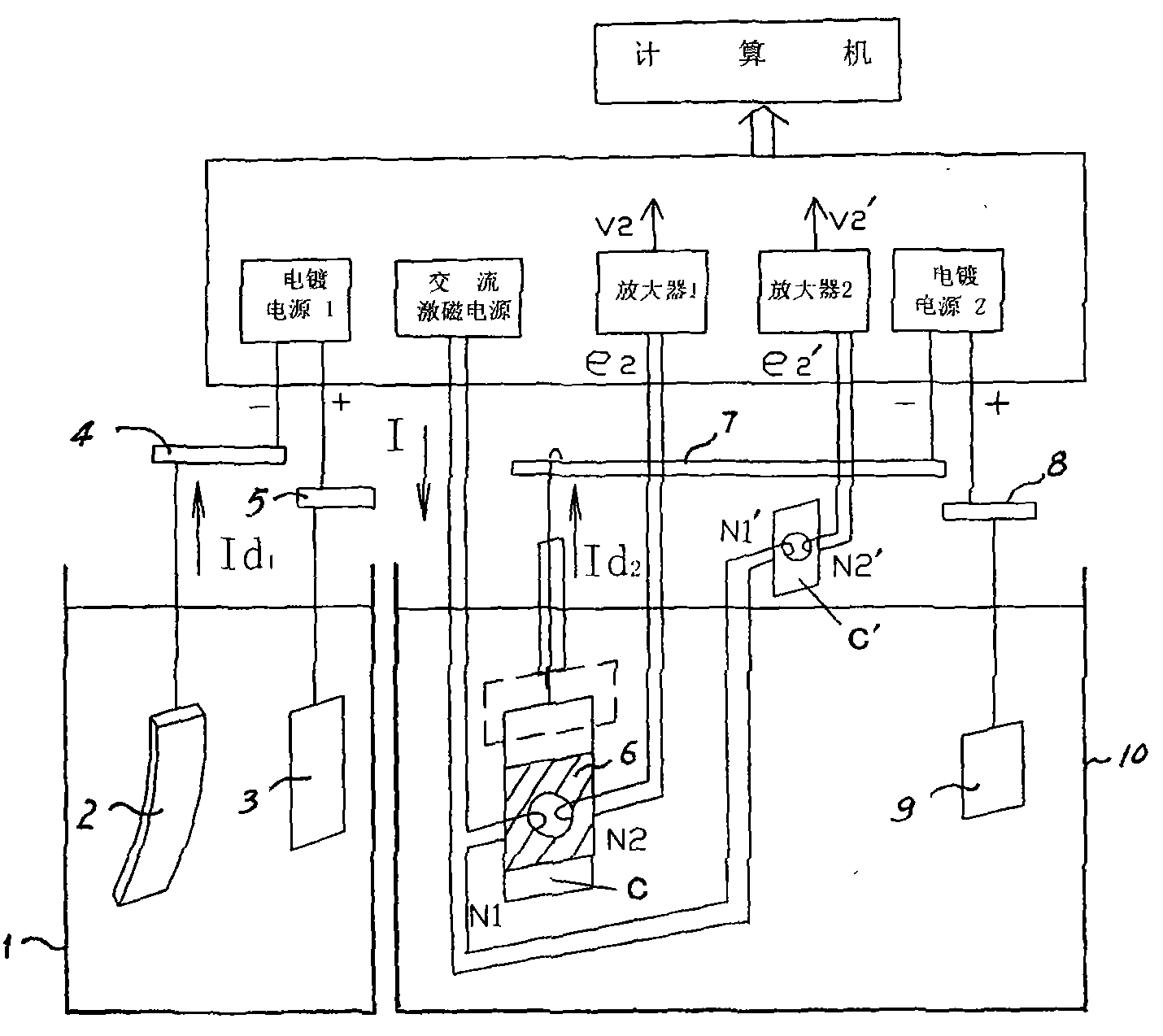

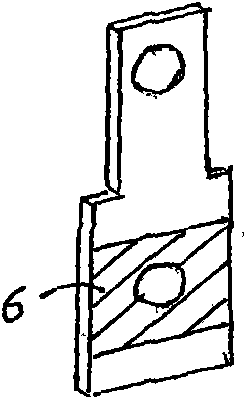

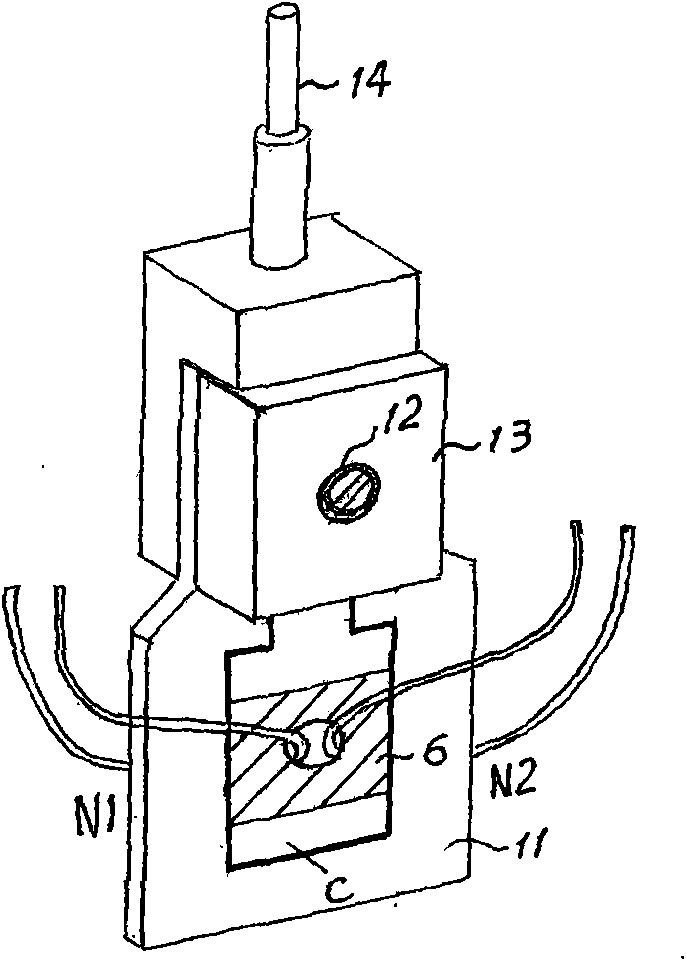

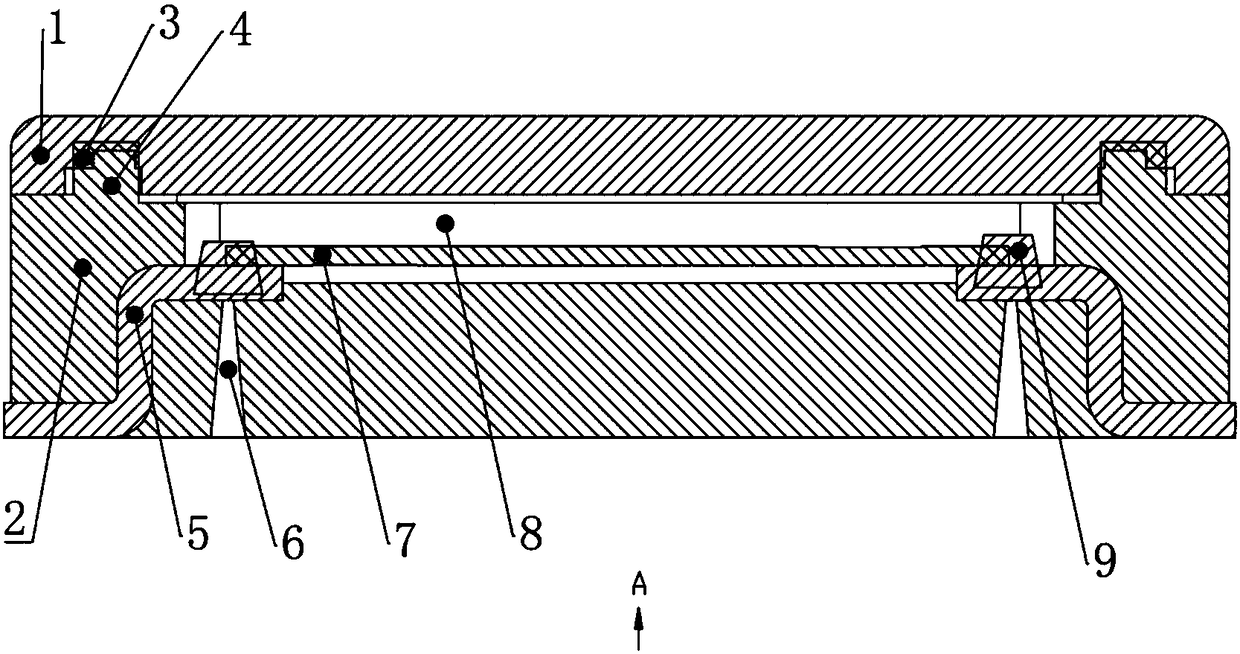

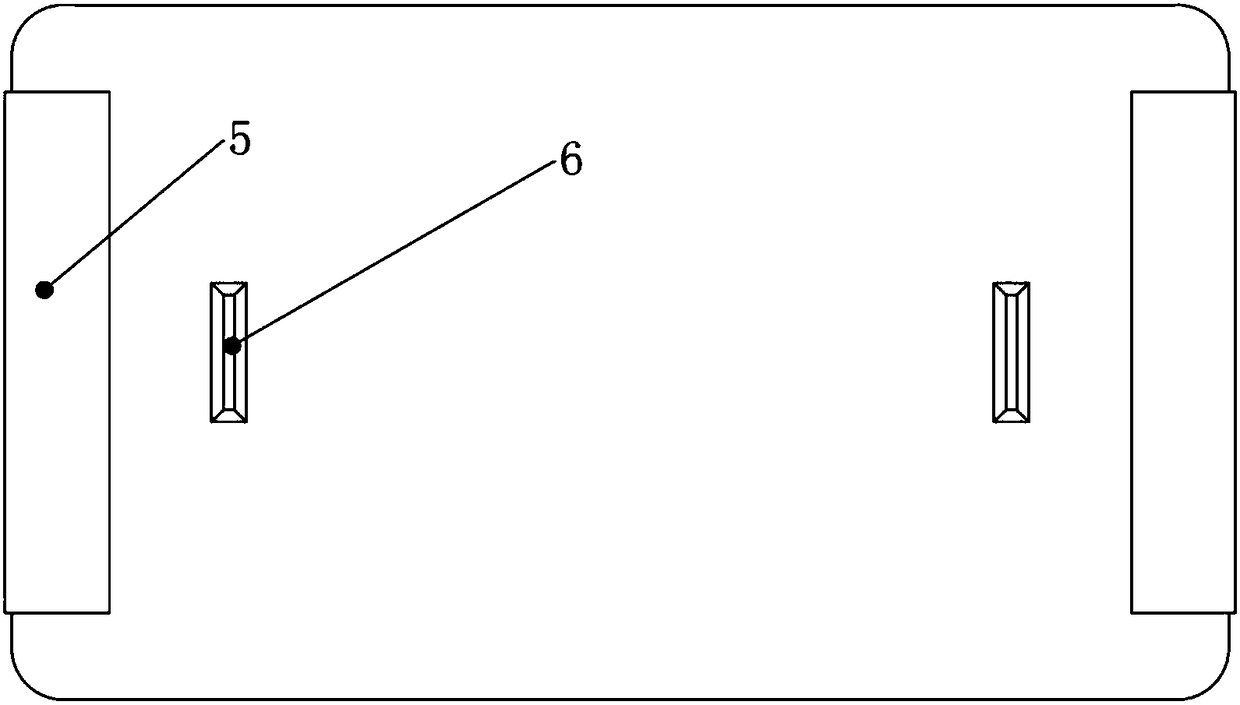

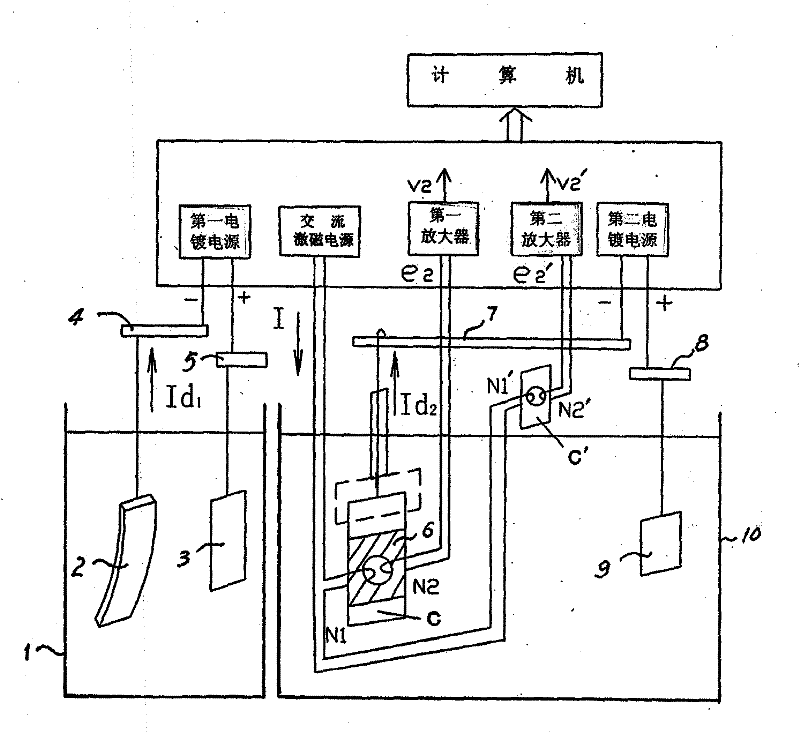

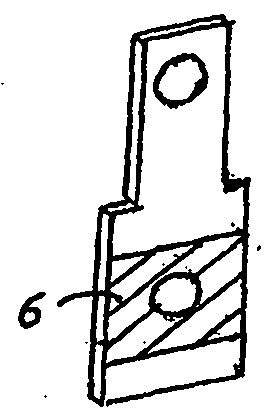

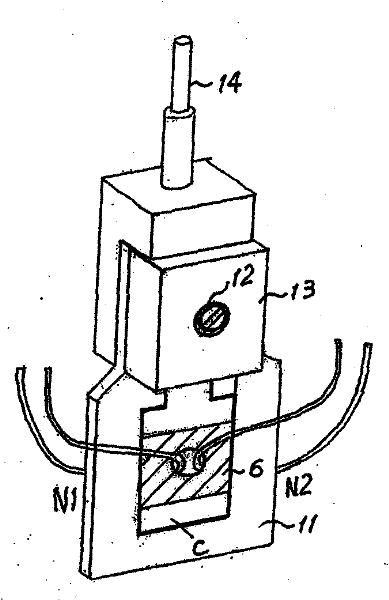

Electroplating layer stress measurement device

InactiveCN101839778AShort measuring cycleHigh measurement accuracyForce measurement by measuring magnetic property varationHorizontal stressStress measurement

The invention relates to an electroplating layer stress measurement device, which consists of an AC excitation power source, an electroplating power source, a measurement sensor, a correction sensor, a cathode piece and a computer. The measurement sensor comprises a magnetic sensing piece C forming a closed magnetic loop, a primary excitation winding N1 and a secondary sensing winding N2 are wound on the magnetic sensing piece C, and insulation paint are coated on the surface of the magnetic sensing piece C except for a plane electroplating area; structure, shape and magnetic property of a magnetic sensing piece C' of the correction sensor are identical to that of the magnetic sensing piece C, the surface is sealed and insulated, primary windings N1 and N1' of the two sensors are connected with the AC excitation power source after being serially connected with each other, and the secondary windings N2 and N2' are respectively connected with amplifiers 1 and 2; and the cathode piece is used for measuring the type of the stress. The device has the advantages of short measurement period, high application measurement precision within the low-stress range and the like; and besides the type of the plating layer stress and the horizontal stress value, the device also can be used for measuring the connection force between the metal plating layer and the base body during the electric crystallization process.

Owner:邱安生

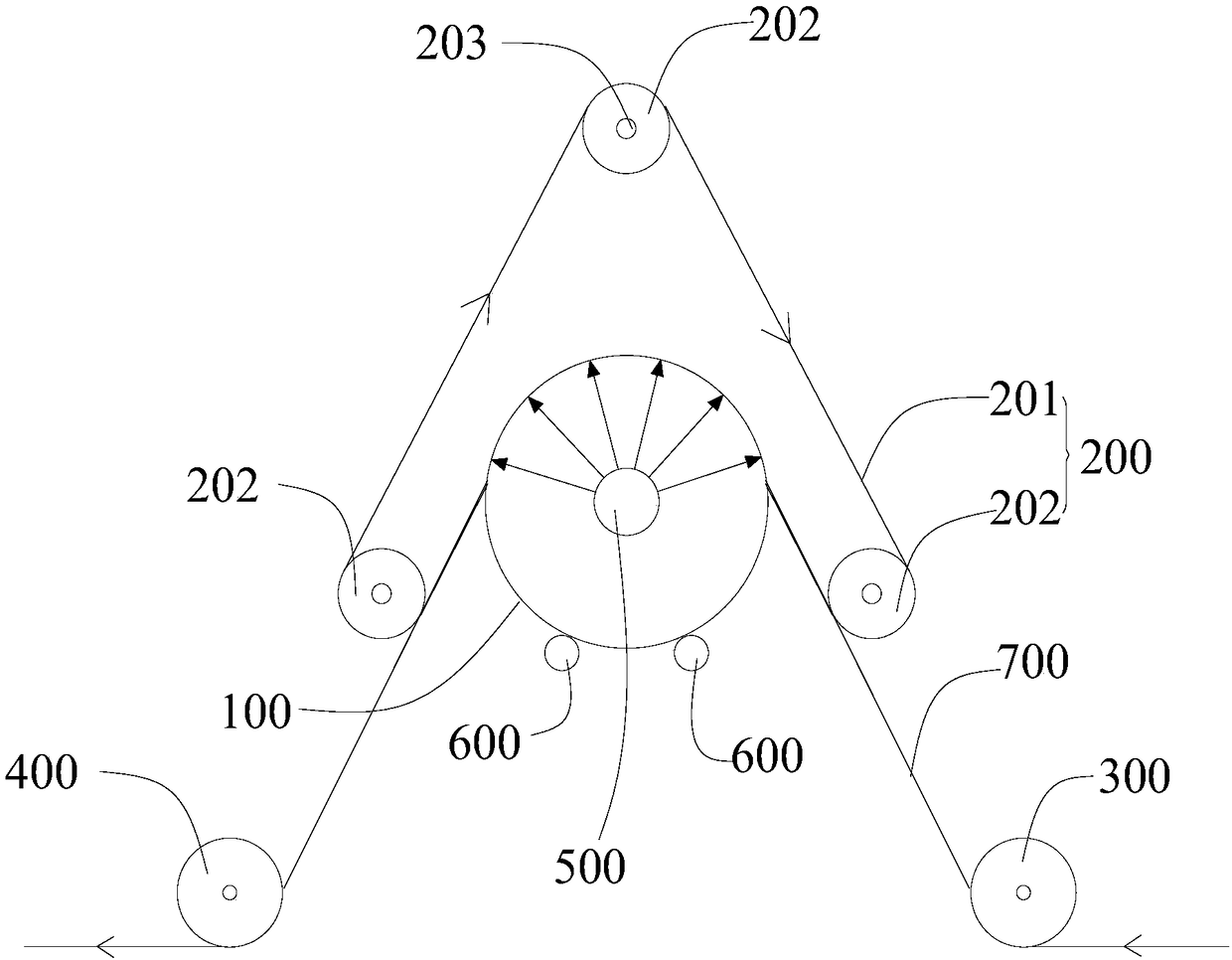

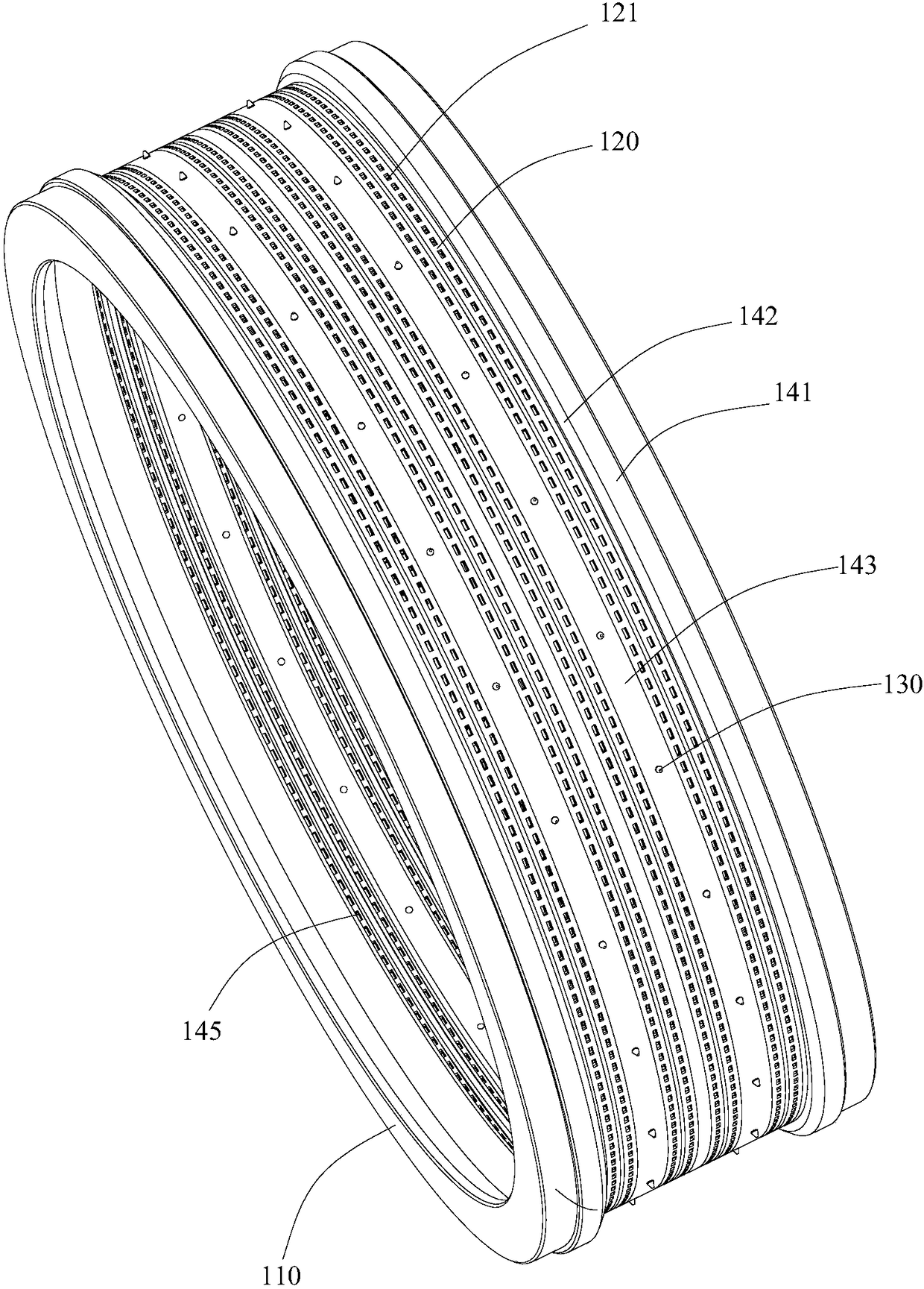

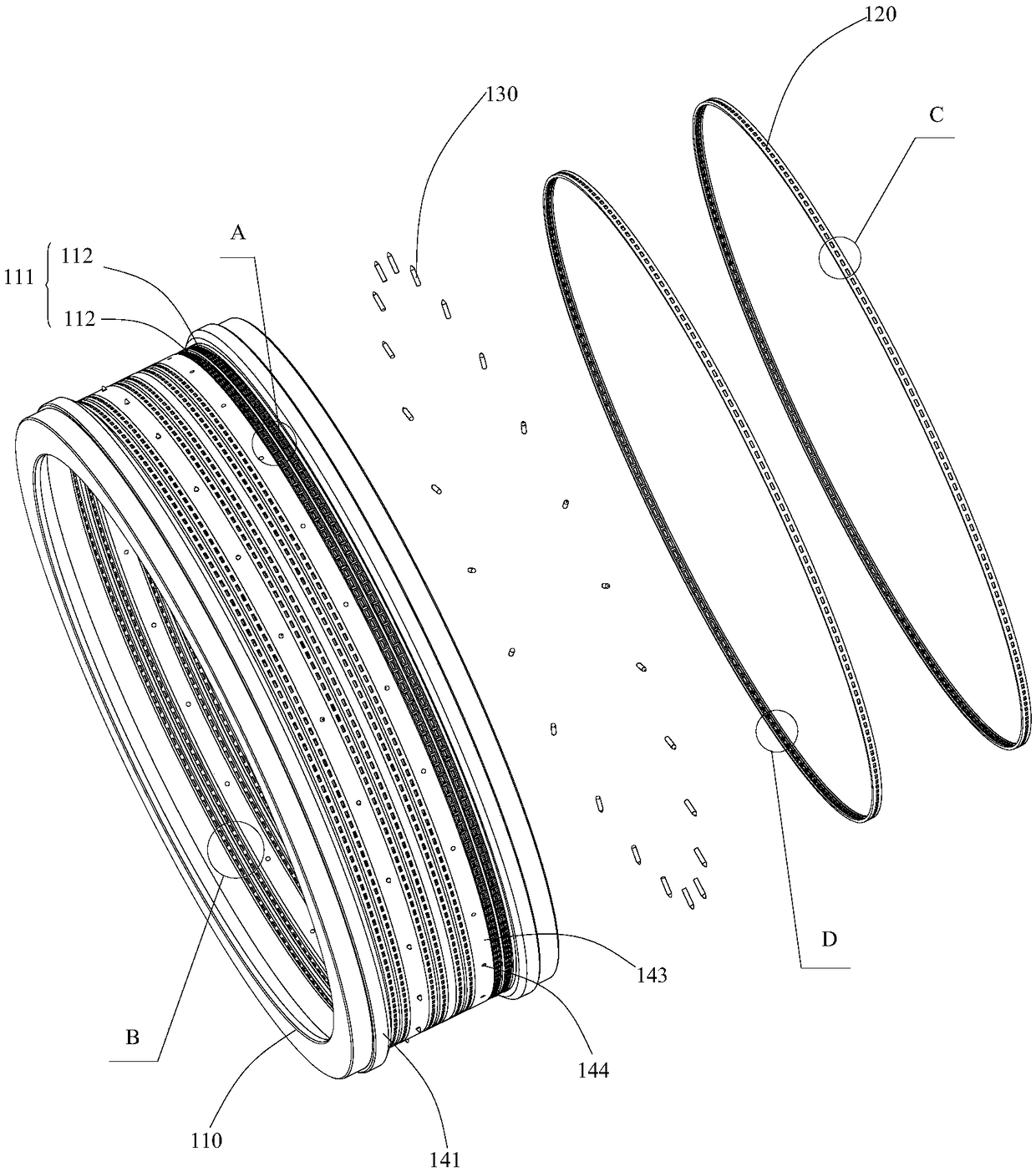

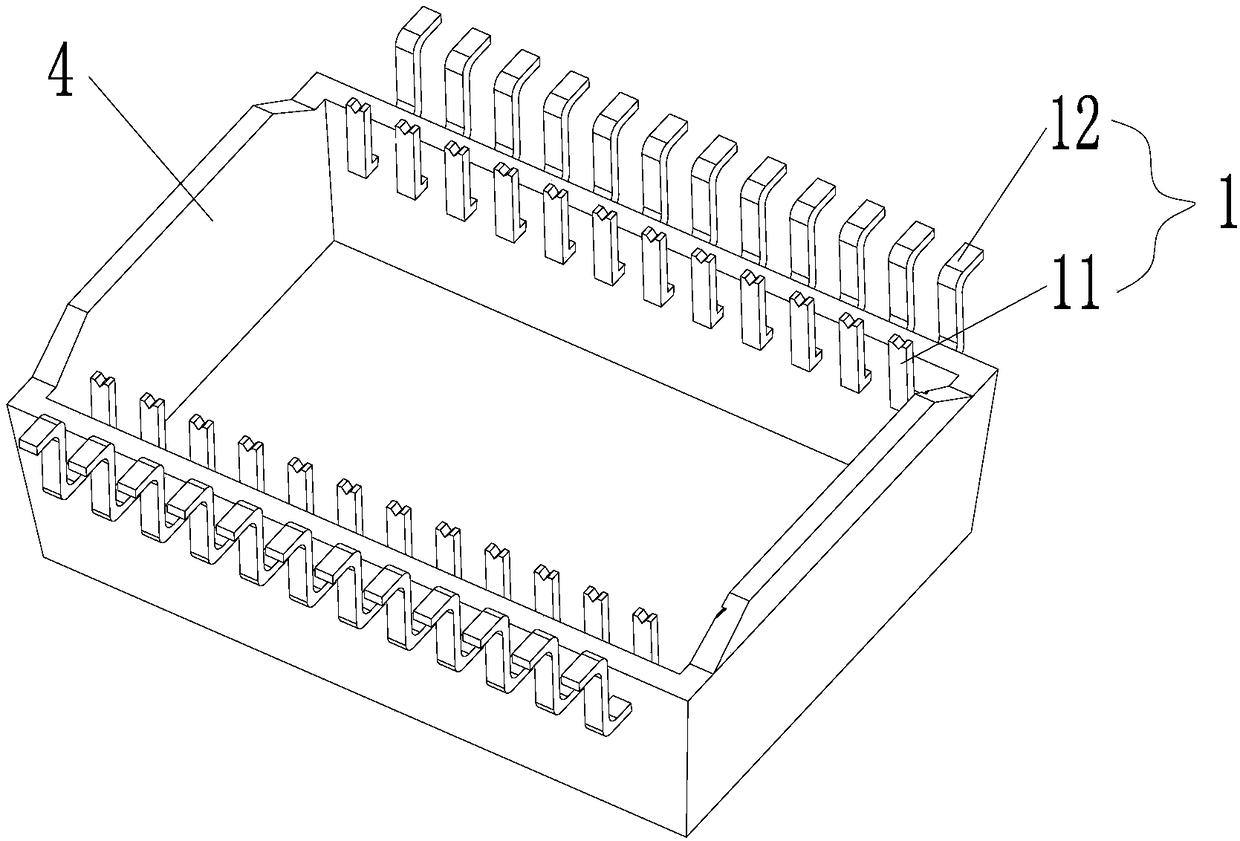

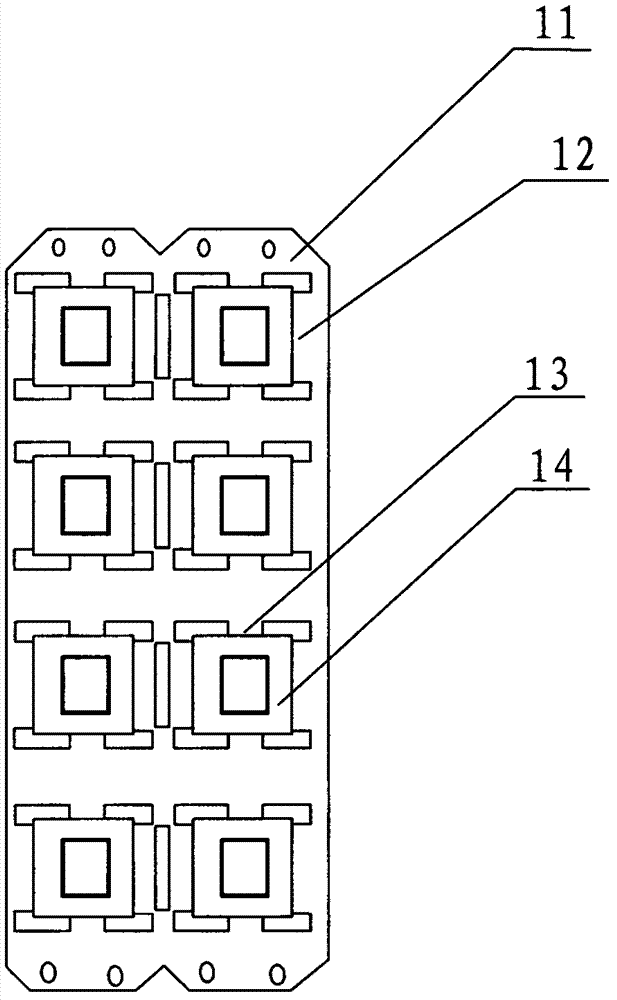

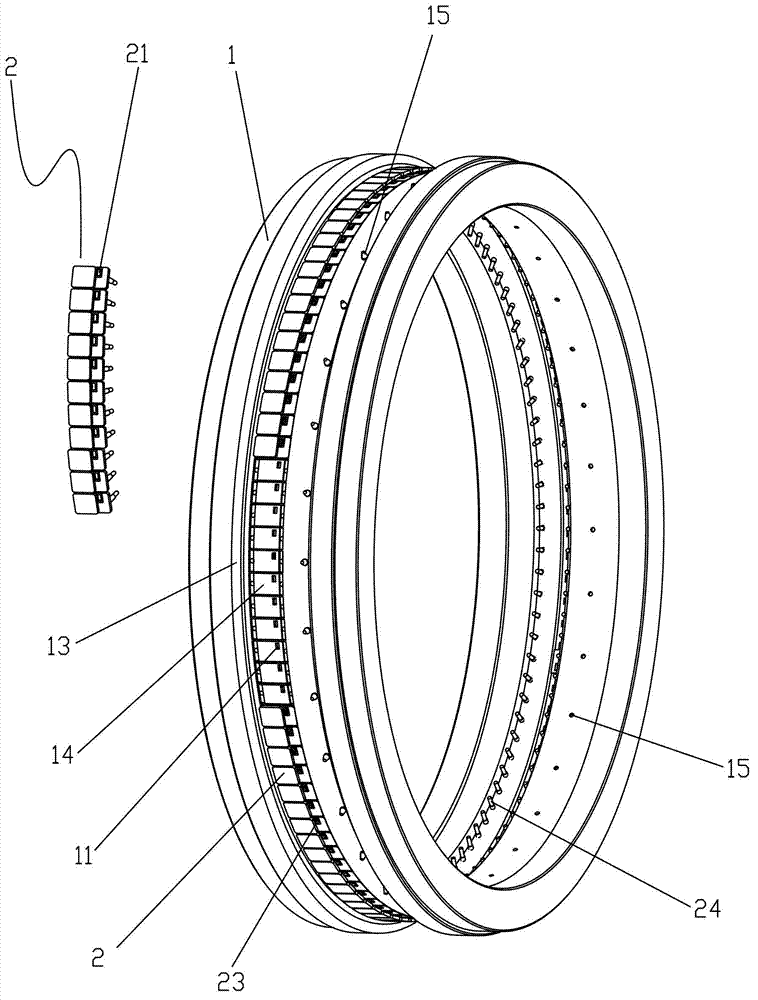

Multi-row lead frame electroplating equipment

PendingCN108385145AImprove plating efficiencyPrevent leakageElectrolysis componentsLead frameElectroplating

The invention relates to multi-row lead frame electroplating equipment. The multi-row lead frame electroplate equipment comprises a mold, a pressing device, a sheet feeding wheel, a sheet dischargingwheel and an anode nozzle arranged in the mold. The mold comprises a mold body, a plurality of mold belts and at least two rows of mold nail groups, wherein the mold body is rotatable, the mold beltsare arranged on the outer peripheral wall of the mold body, and the mold nail groups are arranged on the outer peripheral wall of the mold body at intervals. The mold body is provided with a pluralityof groups of electroplating areas which can simultaneously complete electroplating of a multi-row lead frame, thereby effectively improving the electroplating efficiency of the lead frame and reducing the electroplating cost. The pressing device presses the multi-row lead frame on the periphery of the mold, mold pins are used for penetrating through positioning holes in the multi-row lead frame to position the lead frame, so that the lead frame can be tightly adhered to the mold body to prevent electroplating solution from leaking, and the electroplating effect is good.

Owner:ACKOTEC ZHONGSHAN ELECTRONICS PARTS

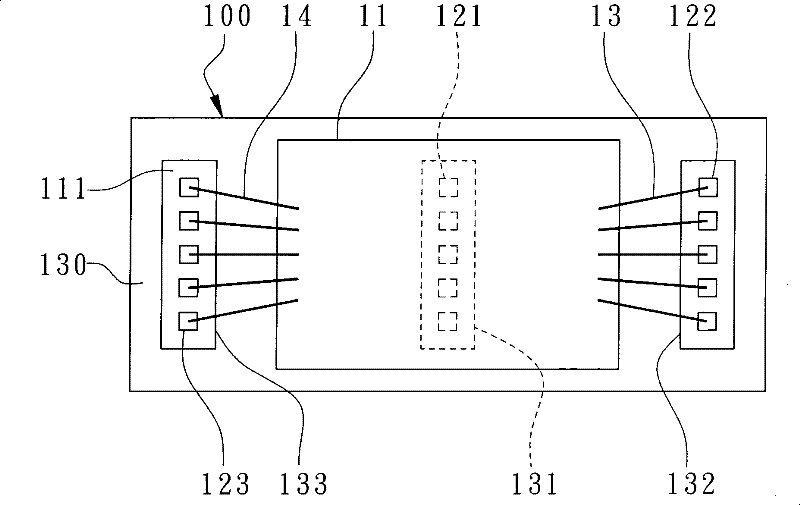

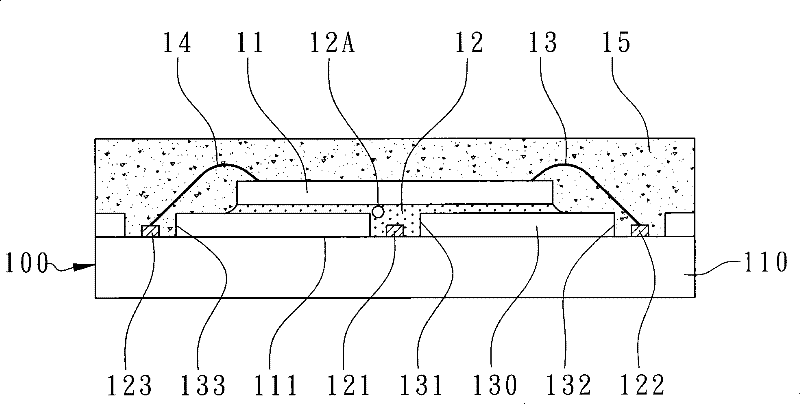

Plastic packaged quartz crystal resonator and preparation method thereof

The invention relates to a plastic packaged quartz crystal resonator, comprising a cover plate, a quartz wafer, a conductive adhesive and a base, wherein the cover plate is a plastic cover plate, thequartz wafer is an electrode-plated quartz wafer, the base comprises a plastic body and a conductive pin that are combined together by a nano-injection molding process, the electrode-plated quartz wafer is solidified in a receiving chamber by the conductive adhesive and is connected to the conductive pin; the cover plate is a permeable plastic cover plate and is peripherally provided with a groovefor receiving protrusions on the base, the plastic body is an opaque plastic body that is provided with a receiving chamber for accommodating a quartz wafer and a projection corresponding to the groove, and the cover plate and the base are fixed by laser welding to seal the quartz wafer. The product of the invention breaks the limitation of the metal and ceramic seal in the crystal industry, andbrings more selectivity to the products used by the customer.

Owner:瓷金科技(广东)有限公司

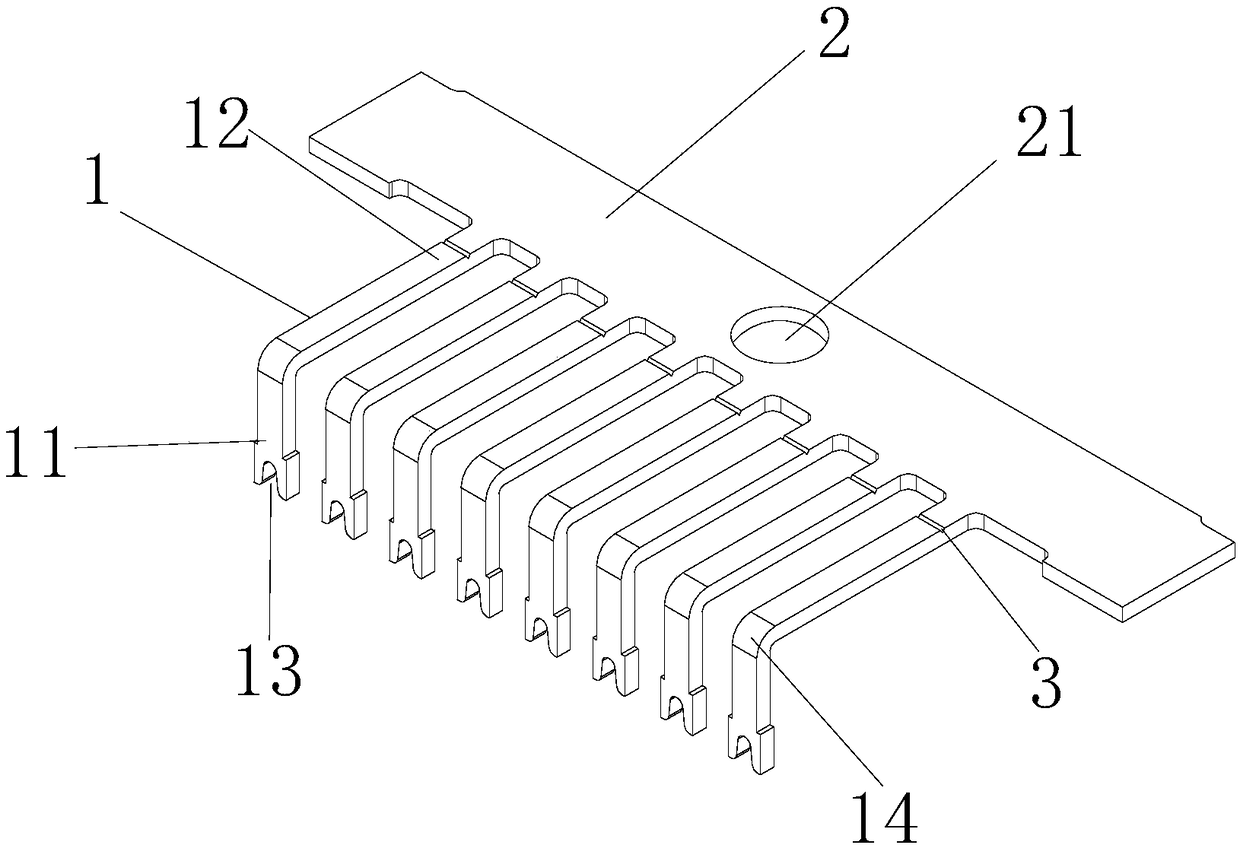

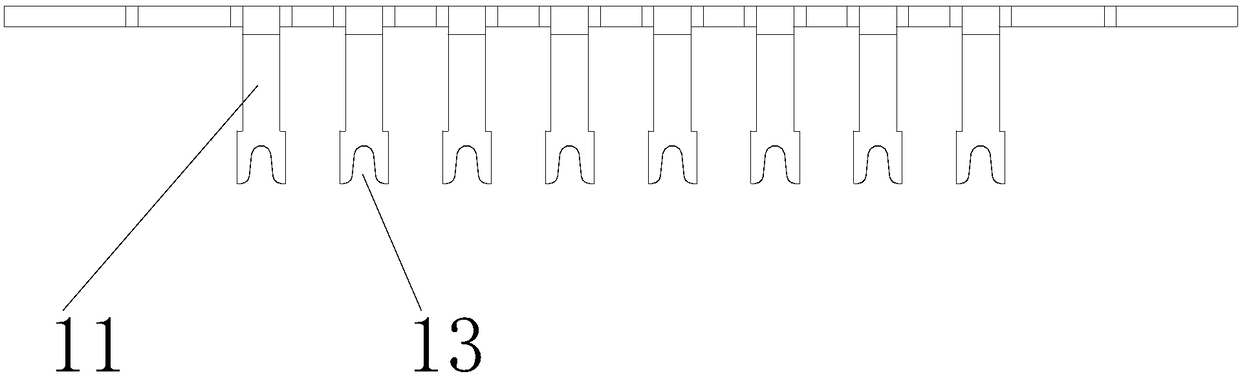

PIN needle material strip

PendingCN108539461AReduce widthReduce lossContact member manufacturingTransformers/inductances coils/windings/connectionsMetal stripsPins needles

The present invention discloses a PIN needle material strip. The PIN needle material strap comprises a PIN needle and a side strip, there is one side strip, the PIN needle is a stripe-shaped structure, one end of the PIN needle is a wiring pin, the other end of the PIN needle is a welding pin, a plurality of PIN needles are connected with the edge of the side strip through one end of the welding pin, and the top ends of the wiring pins of the PIN needles directly form insertion wire grooves for wiring. The PIN needle material strip employs the structure of the PIN needles being connected withthe single side strip, and the wiring pins of the PIN needles directly form the insertion wire grooves to change the wiring mode so as to effectively reduce the wiring efficiency, improve the wiring efficiency, reduce the cutting processing process, effectively improve the processing efficiency, reduce the electroplating area, reduce the material loss caused by cutting, reduce the whole width of the PIN needle material strip, reduce the width of the costumed metal strip and effectively reduce the cost of manufacturing the PIN needle material strip.

Owner:DEYANG ZHIDA PRECISION ELECTRONICS

Outward-convex cavity three-mode resonant structure and filter with resonant structure

The invention discloses an outward-convex cavity multi-mode resonant structure and a filter with the resonant structure. The resonant structure comprises a cavity and a cover plate; a dielectric resonant block and a dielectric supporting frame are arranged in the cavity; at least one end plane of the cavity and / or the dielectric resonant block is convex outwards; the dielectric resonant block andthe dielectric supporting framework form a three-mode dielectric resonant rod; one end or any end of the similar-cubic dielectric resonant block is connected with the dielectric supporting frame separately; the dielectric supporting frame is connected with the inner wall of the cavity; and the dielectric resonant block forms three-mode resonance in three directions of X, Y and Z axis in the cavity. By the adoption of the cavity filter provided by the invention, a high Q value can be obtained while a relatively small distance between the resonant rod and the cavity is ensured, and the tuning range of a tuning screw rod is enlarged; and meanwhile, the sensitivity of the small spacing between the cavity and the dielectric resonant block to the resonance frequency is reduced, the production and debugging are facilitated, and the production cost is lowered.

Owner:HONGKONG FINGU DEV CO LTD

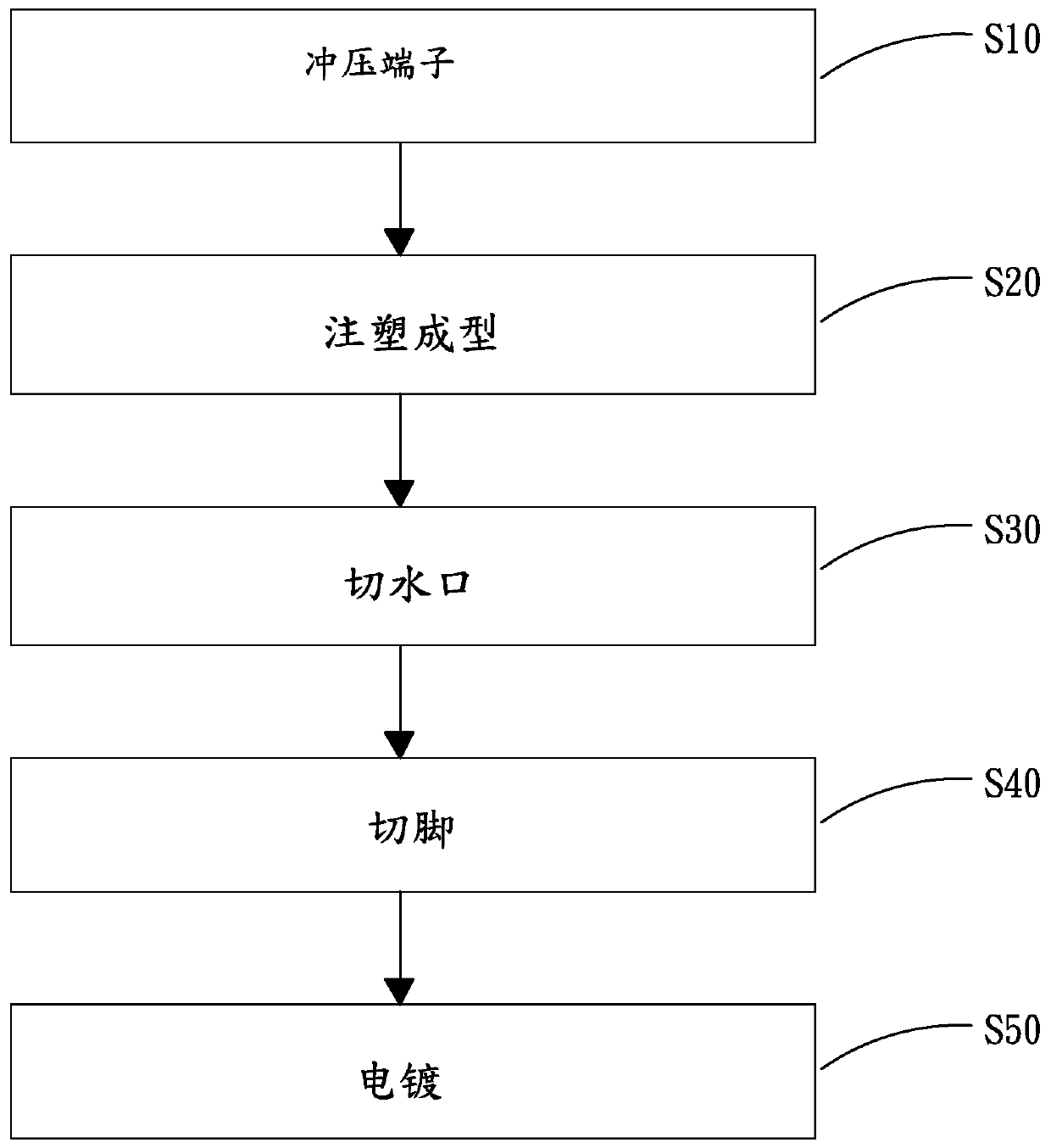

LED support manufacturing method and LED support

ActiveCN110993776AImprove efficiencySurface shininess is not affectedSemiconductor devicesInjection mouldingAir tightness

The invention relates to an LED support manufacturing method. The method comprises the following steps: stamping a terminal: stamping a metal material to obtain the metal terminal; performing injection molding; sealing the metal terminal in an injection mold, injecting a liquid thermosetting material into the injection mold, and heating the injection mold to cure and mold the thermosetting material on the metal terminal to obtain a plastic main body; cutting a water gap, namely, cutting the water gap on the plastic main body; pin cutting, namely, cutting the pin parts, and extending out of theplastic main body, of the metal terminals so as to trim the shape; and electroplating, namely, electroplating the surfaces of the metal terminals extending out of the plastic main body. The inventionfurther provides an LED support obtained through the LED support manufacturing method. The method has the beneficial effects that electroplating is carried out after injection molding and pin cutting, the electroplating area is reduced, the electroplating cost is reduced, a silver layer formed by electroplating is protected, the surface reflectance of the metal terminal is protected, the bindingforce of the metal terminal and plastic is improved, and the air tightness of a product is improved.

Owner:东莞智昊光电科技有限公司

Plastic-packaged quartz crystal resonator shell and preparation method thereof

InactiveCN108259018AAirtightnessAchieve weldingImpedence networksQuartz crystal resonatorEngineering

The invention relates to a plastic-packaged quartz crystal resonator shell comprising a cover plate and a pedestal, wherein the cover plate is a plastic cover plate, the pedestal comprises a plastic main body and conductive pins, an accommodating chamber for accommodating a quartz wafer is arranged on the plastic main body, the conductive pins and the plastic main body are combined together via ananometer injection molding process, and the cover plate and the pedestal are fixed together to seal the quartz wafer. The cover plate can be the light-permeable plastic cover plate, grooves for accommodating bumps on the pedestal are arranged in the periphery of the cover plate, the pedestal comprises the plastic main body and the conductive pins, the plastic main body is provided with the accommodating chamber for accommodating the quartz wafer and the bumps corresponding to the grooves, the plastic main body is not light-permeable, and the cover plate and the pedestal are fixed together vialaser welding to seal the quartz wafer. The product provided by the invention breaks the limitation of sealing of metal and ceramic in the crystal industry, and more selectivity is provided for the products used by the customers.

Owner:瓷金科技(广东)有限公司

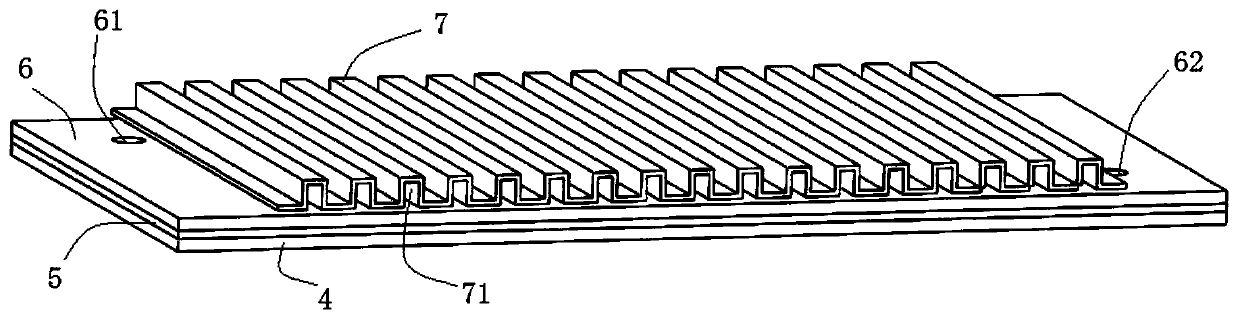

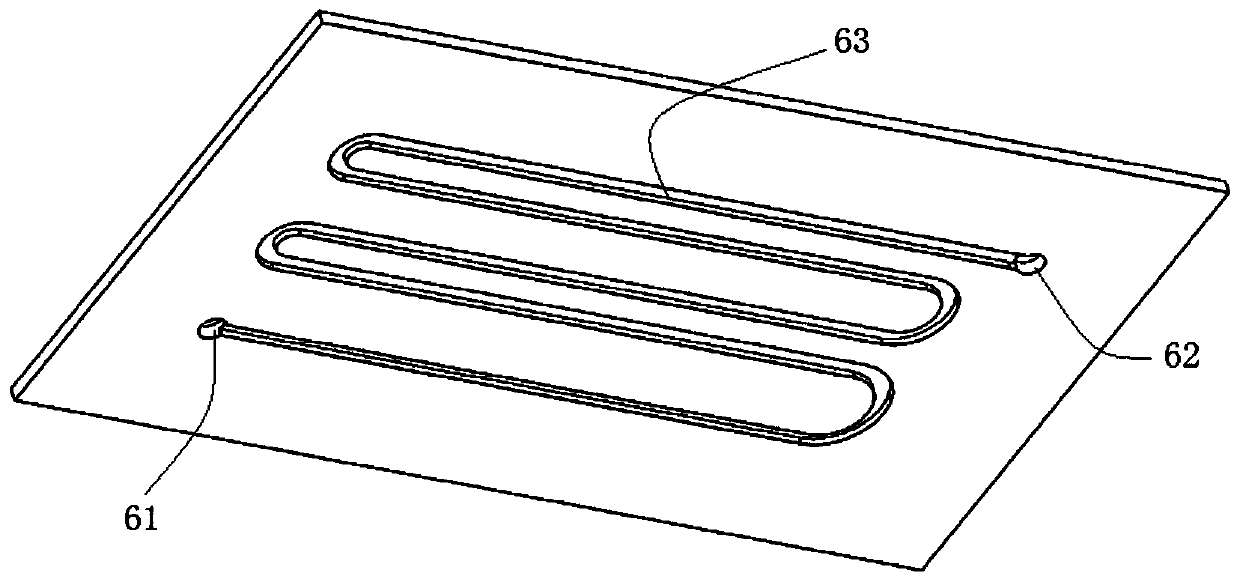

Enclosed air-cooling fuel cell

PendingCN109755610AExtended service lifeReduce plating areaFuel cell heat exchangeEngineeringOxygen supply

The invention relates to an enclosed air-cooling fuel cell. The enclosed air-cooling fuel cell comprises a positive electrode plate and a membrane electrode assembly and comprises a negative electrodeplate and cooling plates, wherein the membrane electrode assembly is sandwiched between the positive electrode plate and the negative electrode plate, the cooling plates are arranged on the negativeelectrode plate in a lamination way, a cooling passage is formed between the cooling plates and the negative electrode plate and is used for natural air to circulate, an oxygen supply passage is formed between the negative electrode plate and the membrane electrode assembly and is used for oxygen or filter air to circulate, and the cooling passage and the oxygen supply passage are isolated with each other. Impurity-containing air is only used for cooling and is not in contact with the membrane electrode assembly any longer, the influence of low-air quality on lifetime of the membrane electrodeassembly is further reduced, and the service lifetime of the membrane electrode assembly is prolonged.

Owner:ZHENGZHOU AFFIRMATIVE TECH LTD

Manufacturing method of circuit board with selectively plated copper and tin

InactiveCN101521991BReduce plating areaReduce pollutionConductive material chemical/electrolytical removalPrinted element electric connection formationCopper platingReversal film

The invention relates to a manufacturing method of a circuit board with selectively plated copper and tin, comprising the following steps: coating a plating-resistant cover film on a copper precipitatThe invention relates to a manufacturing method of a circuit board with selectively plated copper and tin, comprising the following steps: coating a plating-resistant cover film on a copper precipitation circuit board or a circuit board plated with copper at first time, and then bonding positive sheets of all metal holes and hole rings, which are contained in circuit diagrams, on the plating-resision circuit board or a circuit board plated with copper at first time, and then bonding positive sheets of all metal holes and hole rings, which are contained in circuit diagrams, on the plating-resistant cover film to form a primary circuit after exposure and development; plating copper and tin on the hole walls of all the metal holes and the hole rings and then carrying out film de-coating; coattant cover film to form a primary circuit after exposure and development; plating copper and tin on the hole walls of all the metal holes and the hole rings and then carrying out film de-coating; coating a corrosion-resistant cover film on the de-coated circuit board, and then bonding negative sheets of the circuit diagrams on the corrosion-resistant cover film to form a secondary circuit after exing a corrosion-resistant cover film on the de-coated circuit board, and then bonding negative sheets of the circuit diagrams on the corrosion-resistant cover film to form a secondary circuit after exposure and development; etching the circuit diagrams and then carrying out film de-coating and tin de-coating; and manufacturing a circuit board product after welding prevention, exposure, developmentposure and development; etching the circuit diagrams and then carrying out film de-coating and tin de-coating; and manufacturing a circuit board product after welding prevention, exposure, development, element mark printing, tin spraying, anti-oxidation process or turmeric and outline process. The invention selectively plates copper and tin, thereby greatly reducing the amount of copper and tin to, element mark printing, tin spraying, anti-oxidation process or turmeric and outline process. The invention selectively plates copper and tin, thereby greatly reducing the amount of copper and tin togreatly reduce the environmental pollution from tin de-coating process, effectively saving the copper, tin, water, electricity, chemical materials, energy charges and manpower and effectively reducin greatly reduce the environmental pollution from tin de-coating process, effectively saving the copper, tin, water, electricity, chemical materials, energy charges and manpower and effectively reducing the production costs for enterprises.g the production costs for enterprises.

Owner:深圳市源基电子科技有限公司 +1

A cavity high-q three-mode dielectric resonant structure and a filter containing the resonant structure

The patent of the invention discloses a cavity high-Q three-mode dielectric resonant structure and a filter containing the resonant structure, including a cavity and a cover plate, and the cavity is composed of a similar cube dielectric resonator block and a dielectric support frame, similar to a cube The dielectric resonator block and the dielectric support frame form a three-mode dielectric resonator rod. There is air between the three-mode dielectric resonator rod and the inner wall of the cavity. One end or any end of the dielectric resonator block similar to a cube is respectively connected to the dielectric support frame. The dielectric support frame and the cavity The inner walls are connected, similar to a cube dielectric resonator block to form a three-mode resonance in the three directions of the X, Y, and Z axes of the cavity. The volume of the cavity filter using the present invention is reduced by 40% compared with the volume of the existing cavity filter, and the insertion loss is reduced by more than 30%, which can ensure high Q at a small distance between the resonant rod and the cavity value.

Owner:HONGKONG FINGU DEV CO LTD

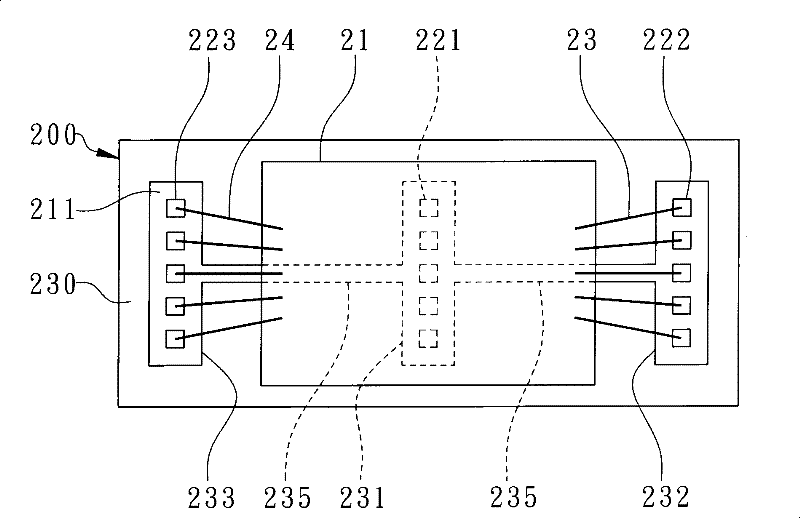

Universal type basal plate packaged by semiconductor and semiconductor packaging structure

InactiveCN101609824BAvoid residueAvoid blockingSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageMechanical engineering

The invention discloses a universal type basal plate packaged by a semiconductor and a semiconductor packaging structure. The universal type basal plate comprises a basal plate body, two groups of common connecting fingers, a group of redistribution connecting fingers and a welding prevention layer, wherein the common connecting fingers and the redistribution connecting fingers are arranged on the basal plate body, and the welding prevention layer is formed on the basal plate body. The redistribution connecting fingers are positioned between the two groups of common connecting fingers. The welding prevention layer is provided with an opening used for exposing the redistribution connecting fingers. Two or more exhaust grooves are formed on the welding prevention layer, do not penetrate through the welding prevention layer, are connected with the opening, extend towards the side edge of the basal plate body, are not communicated with an opening used for exposing the common connecting fingers and are used as a path through which gas is outwards exhausted when crystals are stuck. When a chip with large size is arranged, the problems that air bubbles remain in the opening and crystal sticking glue spills to pollute the common connecting fingers can be solved simultaneously. In an embodiment, a line for connecting the redistribution connecting fingers can be overlapped with the exhaust grooves in a staggered way but is not exposed so as to increase the configuration elasticity of the exhaust grooves.

Owner:POWERTECH TECHNOLOGY INC

Manufacturing method of circuit board without tin plating and tin removing

InactiveCN101489355BAvoid heavy pollutionSave potionConductive material chemical/electrolytical removalCopper platingTin plating

A method for manufacturing circuit board which is free of tin plating and tin removing comprises the following steps: a. coating plating-resistant covering film on the circuit board after copper deposition or the first time of copper plating, then adhibiting the positive film of all metal holes and hole rings in the circuit pattern on the covering film for forming a primary circuit after exposing and developing; b. electroplating copper and nickel on the hole wall and hole ring of all metal holes, then removing the covering film; c. coating etching-resistant covering film on the circuit board after film removing, adhibiting the negative film of circuit pattern on the etching-resistant covering film, and forming the secondary circuit after exposing and developing; d. etching the circuit pattern, then removing film and checking erosion; and e. forming the finished product of circuit board through executing the steps of resistance welding, exposing, developing, printing component symbol or tin spraying or executing oxidation prevention procession. The method of the invention can reduce environment pollution and realize clean production through eliminating electrotinning and tin removing technique, effectively saves metal, water, electricity and chemical material and reduces production cost of enterprise through selectively electroplating copper and nickel.

Owner:陈国富

Recessed cavity three-mode resonant structure and filter comprising same

The invention discloses a recessed cavity multi-mode resonant structure and a filter comprising the same. The recessed cavity three-mode resonant structure comprises a cavity and a cover plate, wherein a medium resonant block and a medium supporting rack are arranged in the cavity; at least one end surface of the cavity and / or the medium resonant block is recessed; the medium resonant block and the medium supporting rack form a three-mode medium resonant rod; one end or an optional end of a similar square medium resonant block is separately connected with the medium supporting rack; the mediumsupporting rack is connected with the inner wall of the cavity; the medium resonant block and the m edium supporting rack form three-mode resonance in the X-axis direction, the Y-axis direction and the Z-axis direction of the cavity. By the cavity multi-mode filter, it can be ensured that high Q value can be obtained under a small distance between the resonant rod and the cavity, the tuning rangeof a tuning screw is expanded, meanwhile, the sensitivity of a small distance between the cavity and the medium resonant block to resonant frequency is reduced, production and debugging are facilitated, and the production cost is reduced.

Owner:HONGKONG FINGU DEV CO LTD

Making method of electric nickel and golden circuit board for saving nickel and gold dosage

InactiveCN101267713BOvercoming major deficienciesReduce dosageConductive material chemical/electrolytical removalCopper platingSecondary circuit

A manufacturing method of an electrolytic nickel and gold wiring board capable of saving dosage of nickel and gold, comprises broaching, copper precipitation, and copperizing on a copper-coated plate. The method is characterized by further comprising: a, adhering a dry film or printing a wet film on the wiring board, then adhering a positive sheet, exposing and developing to form a primary circuit; b, electroplating nickel and gold on all positions to be welded and copper surfaces of metal holes, then stripping; c, printing a wet film or adhering a dry film, then adhering a negative sheet, exposing and developing to form a secondary circuit; d, etching a circuit diagram, removing non-circuit portions, holding circuit portions, then performing stripping and etching detection; e, performingdeoxidation treatment to the wiring board to remove oxides on the copper surfaces; f, after deoxidation treatment, resistance welding, exposing, developing, printing element symbols and machining shapes so as to manufacture the electrolytic nickel and gold wiring board only at the positions to be welded and the metal hole positions. With the method, the area of the nickel and gold can be reduced by 40-60%, thereby saving the noble metal nickel and gold and effectively reducing enterprise production cost.

Owner:陈国富

A special-shaped cavity three-mode resonant structure and a filter containing the resonant structure

The patent of the present invention discloses a special-shaped cavity multi-mode resonance structure and a filter containing the resonance structure, including a cavity and a cover plate, a dielectric resonance block and a dielectric support frame are arranged in the cavity, and at least one end face of the cavity is Concave or convex, at least one end face of the dielectric resonant block is convex or concave, the dielectric resonant block and the dielectric support frame form a three-mode dielectric resonator rod, one end or any end of the dielectric resonant block similar to a cube is connected to the dielectric support frame respectively, the dielectric The support frame is connected with the inner wall of the cavity, and the dielectric resonance block forms three-mode resonance in the three directions of the X, Y, and Z axes of the cavity. The use of the cavity filter of the present invention can ensure that a high Q value can be obtained with a small distance between the resonant rod and the cavity, and at the same time, the tuning range of the tuning screw is increased, and the small distance between the cavity and the dielectric resonant block is reduced. The sensitivity of the resonance frequency is convenient for production debugging and reduces the production cost.

Owner:HONGKONG FINGU DEV CO LTD

LED support

Owner:苏州爱来特光电科技有限公司

A concave cavity three-mode resonant structure and a filter containing the resonant structure

The patent of the present invention discloses a concave cavity multi-mode resonant structure and a filter containing the resonant structure, including a cavity and a cover plate, a dielectric resonator block and a dielectric support frame are arranged in the cavity, the cavity and / or At least one end face of the dielectric resonator block is concave, and the dielectric resonator block and the dielectric support frame form a three-mode dielectric resonator rod, similar to one end or any end of the cube dielectric resonator block connected to the dielectric support frame, and the dielectric support frame is connected to the inner wall of the cavity. The dielectric resonance block and the dielectric support frame form a three-mode resonance in the three directions of the X, Y, and Z axes of the cavity. Using the cavity multimode filter of the present invention can ensure a high Q value at a small distance between the resonant rod and the cavity, increase the tuning range of the tuning screw, and reduce the small distance between the cavity and the dielectric resonator block Sensitivity to resonance frequency facilitates production debugging and reduces production costs.

Owner:HONGKONG FINGU DEV CO LTD

Electroplating layer stress measurement device

InactiveCN101839778BShort measuring cycleHigh measurement accuracyForce measurement by measuring magnetic property varationHorizontal stressStress measurement

The invention relates to an electroplating layer stress measurement device, which consists of an AC excitation power source, an electroplating power source, a measurement sensor, a correction sensor, a cathode piece and a computer. The measurement sensor comprises a first magnetic sensing piece C forming a closed magnetic loop with a primary excitation winding N1 and a secondary sensing winding N2 wound thereon, and insulation paint being coated on the surface of the first magnetic sensing piece C except for a plane electroplating area. The correction sensor comprises a second magnetic sensing piece C' with the same structure, shape and magnetic property with the first magnetic sensing piece C, wherein the surface is sealed and insulated. The primary winding N1 and N1' of the two sensors are connected to the AC excitation power source after series connection, and the secondary winding N2 and N2' are respectively connected to a first amplifier and a second amplifier 2. The cathode piece is used for measuring the type of the stress. The electroplating layer stress measurement device has the advantages of short measurement period, high application measurement precision within the low-stress range and the like; and besides the type of the plating layer stress and the horizontal stress value, the device also can be used for measuring the connection force between the metal plating layer and the base body during the electric crystallization process.

Owner:邱安生

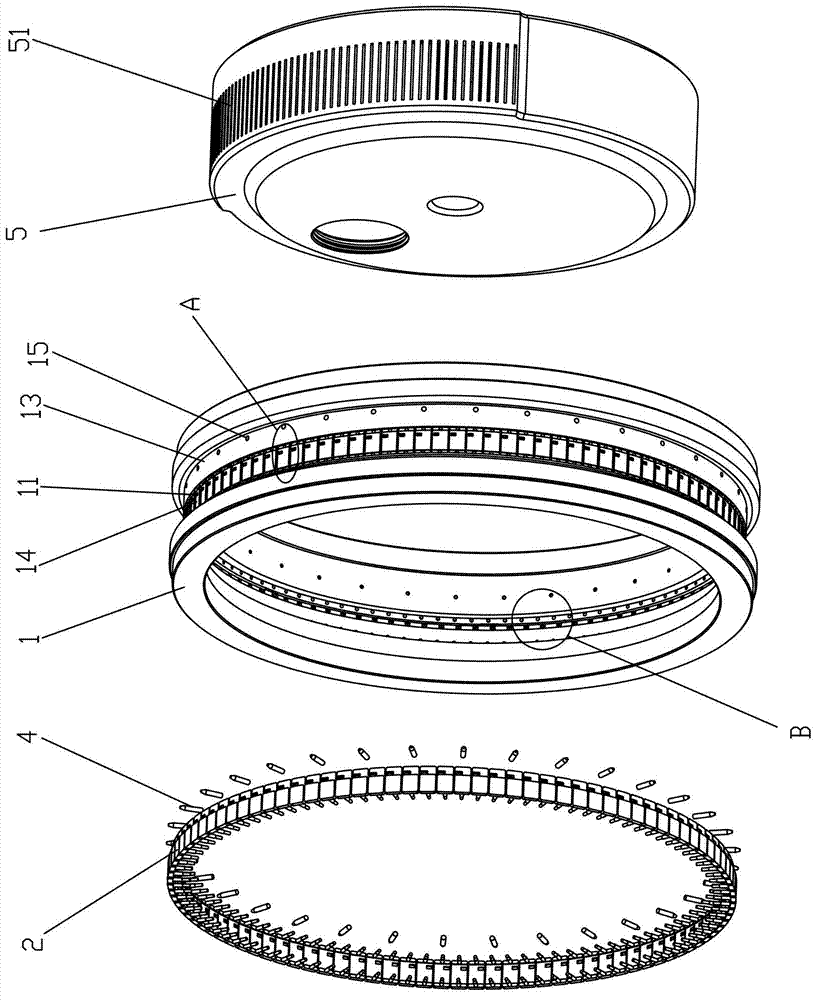

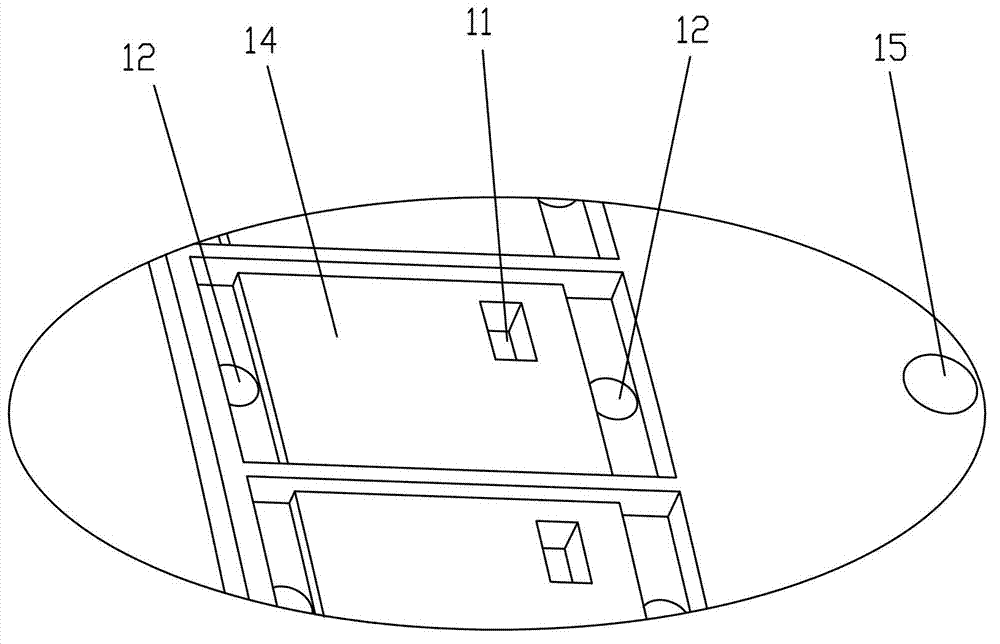

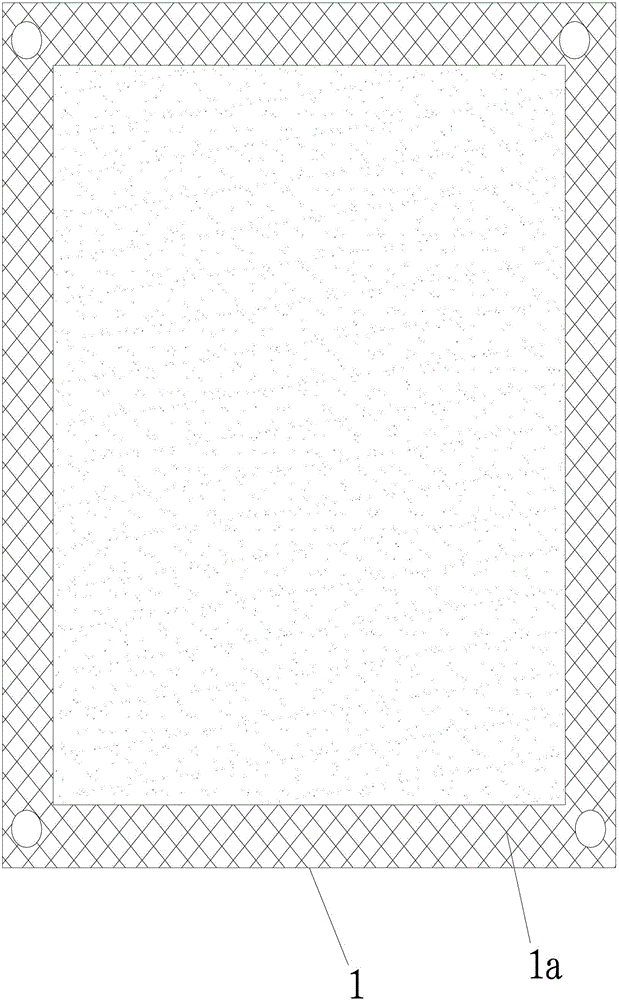

An electroplating mold for high-precision selective electroplating

ActiveCN102817052BPrecise plating position areaPrecise DimensionsSemiconductor/solid-state device detailsSolid-state devicesLayer thicknessElectroplating

The present invention discloses an electroplating mold for electroplating with characteristics of high precision and selectivity. The electroplating mold comprises a roller type mold body and an elastic mold zone, wherein the elastic mold zone is arranged on the outer periphery wall of the mold body, and is provided for covering a non-electroplating region on a lead wire frame. The mold body is circumferentially provided with a plurality of liquid spraying holes. The elastic mold zone is provided with spray plating ports corresponding to the liquid spraying holes. The mold body is circumferentially provided with a positioning device for fixing the lead wire frame on the outer periphery of the elastic mold zone. According to the present invention, the outer periphery of the mold body is additionally provided with the positioning mold nail and the precise elastic mold zone, such that the electroplating position region is precise, the size is accurate, the electroplating area of the electroplating region is small, the electroplating boundary is clear, precision is high, the uneven plating layer thickness is prevented, and unclear plating layer boundary is prevented; and the electroplating region is precisely positioned so as greatly reduce unnecessary loss and waste of precious metals, and save cost.

Owner:ACKOTEC ZHONGSHAN ELECTRONICS PARTS

A circuit board electroplating process for anti-burning board

Owner:SHENZHEN XINGDA PCB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com