PCB electrogilding technology

A PCB board and electro-gold technology, which is applied in the field of printed circuit boards, can solve the problems of waste of precious metals, increase production costs, and gold consumption, and achieve the effects of saving gold, reducing production costs, and reducing the area to be plated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following will clearly and completely describe the technical solutions in the embodiments of the present invention in conjunction with the accompanying drawings.

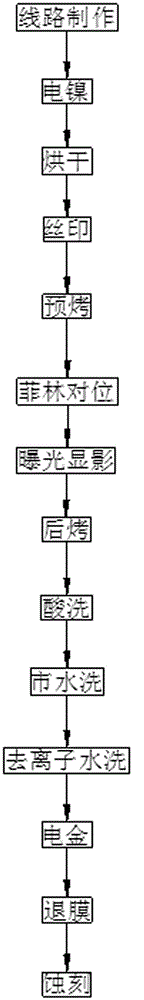

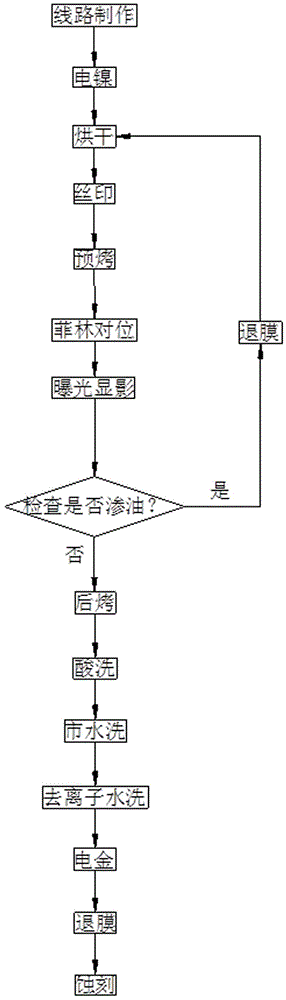

[0020] refer to figure 1 , the embodiment of the present invention provides a kind of PCB electro-gold process, comprising the following steps: circuit making: making circuit on the circuit board after copper plating; electro-nickel: electroplating nickel on the electro-nickel area of the circuit board; drying : drying the circuit board after electro-nickel; silk screen printing: use photosensitive ink to carry out silk screen printing on the circuit board; pre-baking: pre-baking the circuit board after silk screen printing; Alignment; exposure and development: exposure and development of the film after alignment; post-baking: post-baking of the circuit board after exposure and development; pickling: pickling of the circuit board after post-baking; city water washing: pickling After the circuit board i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com