Universal type basal plate packaged by semiconductor and semiconductor packaging structure

A general-purpose semiconductor technology, applied in semiconductor devices, semiconductor/solid-state device parts, electric solid-state devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

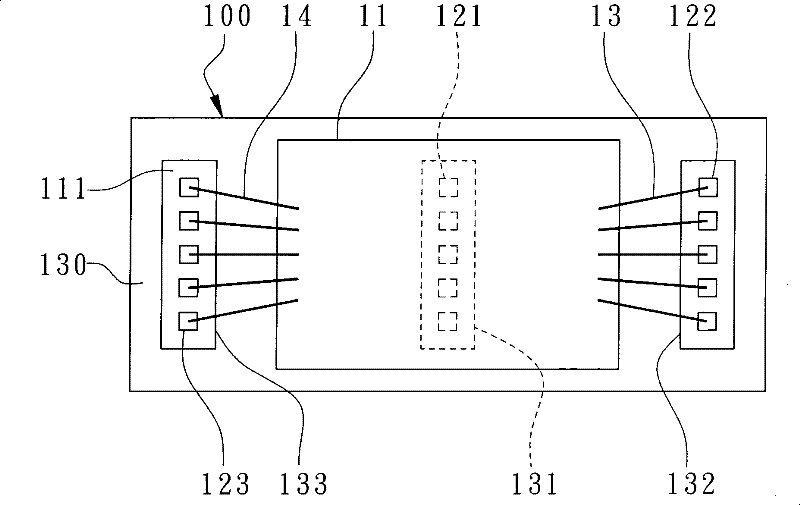

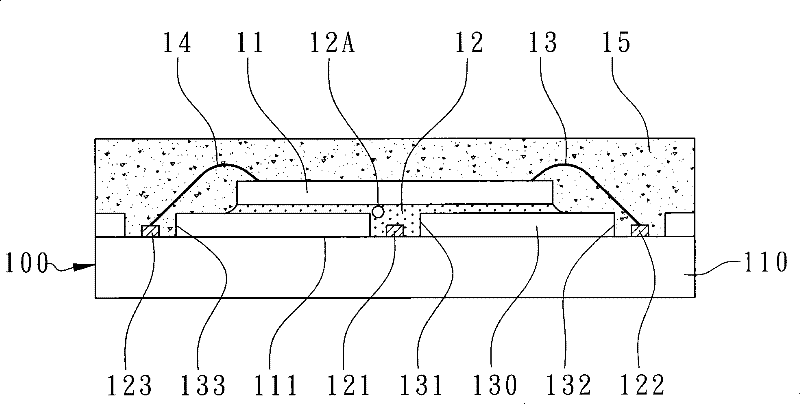

[0087] According to the first embodiment of the present invention, a general-purpose substrate for semiconductor packaging is illustrated in Figure 3A surface diagram of Figure 3B cross-sectional diagram of the Figure 3C 3D schematic diagram of . The universal substrate 300 mainly includes a substrate body 310, two or more first set of fingers 321, two or more second sets of fingers 322, two or more third sets of fingers 323 and Solder mask 330 . see Figure 3A As shown, the substrate body 310 has a surface 311 serving as a mounting surface for disposing chips. The surface 311 may have a first edge 312 , a second edge 313 , a third edge 314 and a fourth edge 315 . In this embodiment, the second edge 313 is parallel to the third edge 314, the first edge 312 is parallel to the fourth edge 315, and the first edge 312 connects the second edge 313 and the second edge 313. Three Edges 314 . The fourth edge 315 also connects the second edge 313 and the third edge 314 .

[...

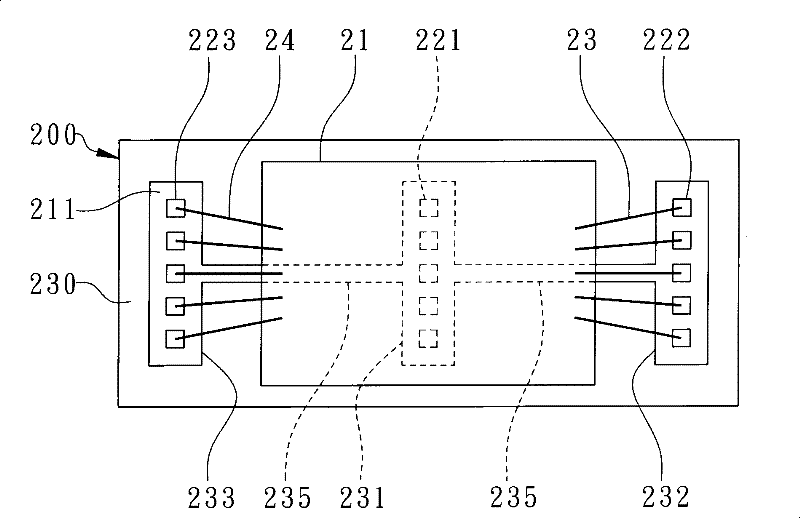

no. 2 Embodiment

[0103] According to the second embodiment of the present invention, another general-purpose substrate for semiconductor packaging is exemplified in Figure 6A The schematic diagram of the substrate surface and Figure 6B cross-sectional schematic diagram. The basic structure of the general-purpose substrate 400 is the same as that of the first embodiment, and the same components are denoted by the same reference numerals, which will not be repeated here. The main components of the universal substrate 400 are the substrate body 310 , the first set of fingers 321 , the second set of fingers 322 , the third set of fingers 323 and the solder mask 330 . see Figure 6B As shown, the first set of fingers 321 are located between the second set of fingers 322 and the third set of fingers 323 . The first opening 331 of the solder resist layer 330 exposes the first set of fingers 321 . The solder resist layer 330 further has a second opening 332 and a third opening 333 to expose the ...

no. 3 Embodiment

[0106] According to the third embodiment of the present invention, another general-purpose substrate for semiconductor packaging is illustrated in Figure 7 Schematic diagram of the substrate surface. The basic structure of the universal substrate 500 is roughly the same as that of the first embodiment, and the same components are denoted by the same reference numerals, which will not be repeated here. The main components of the universal substrate 500 are the substrate body 310 , the first set of fingers 321 , the second set of fingers 322 , the third set of fingers 323 and the solder mask 330 . The first opening 331 of the solder mask 330 exposes the first set of fingers 321 , the second opening 332 of the solder mask 330 exposes the second set of fingers 322 , and the third opening of the solder mask 330 333 exposes these third set of fingers 323 . Likewise, the first exhaust grooves 340 are formed on the exposed surface of the solder resist layer 330 but do not penetrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com