Manufacturing method of circuit board with selectively plated copper and tin

A technology for circuit boards and copper electroplating, which is used in the manufacture of printed circuits, removal of conductive materials by chemical/electrolytic methods, and printed circuits. It can solve the waste of precious metal chemical materials, environmental pollution, and increase production costs. The effect of production, reducing production cost and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

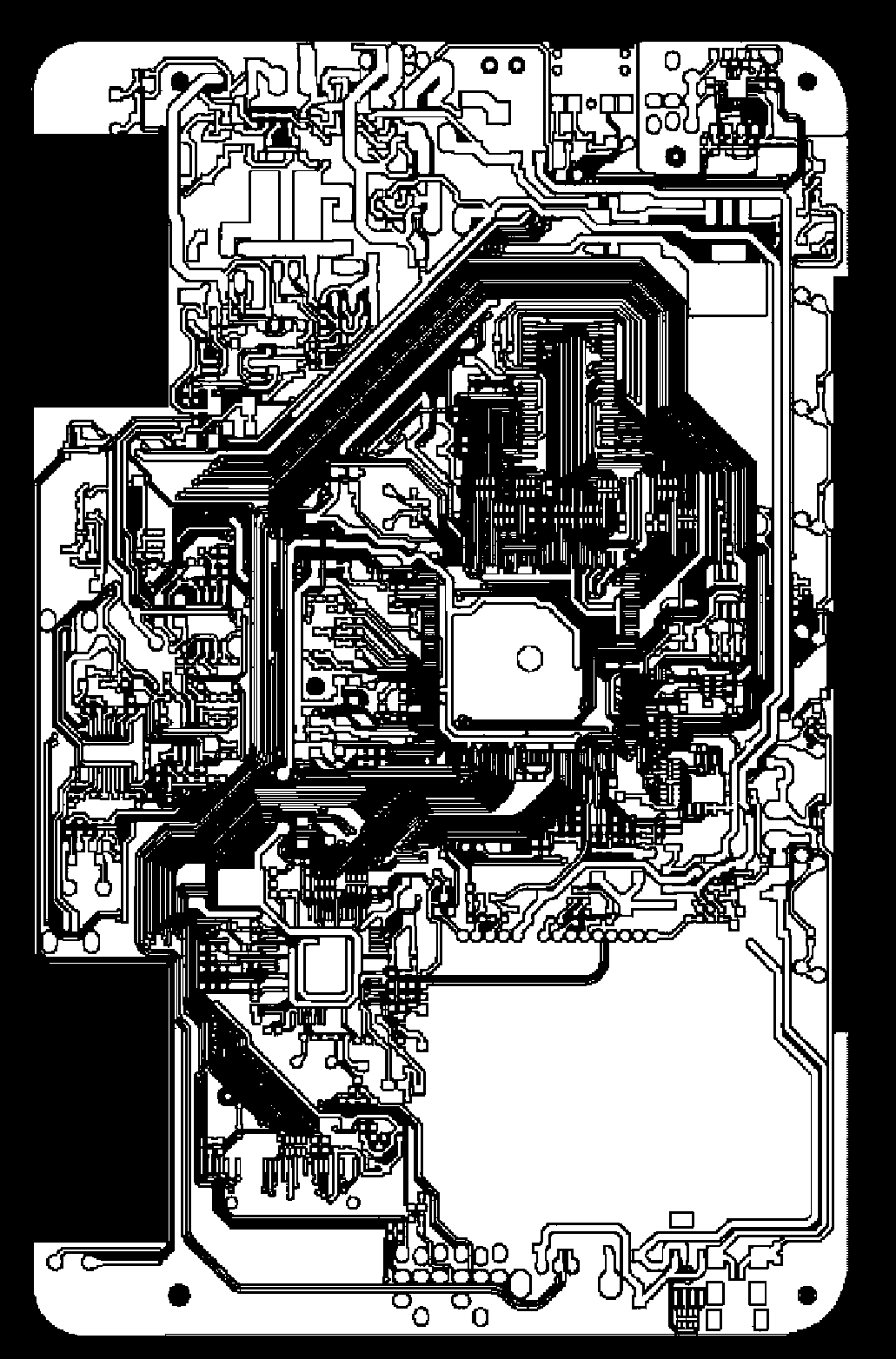

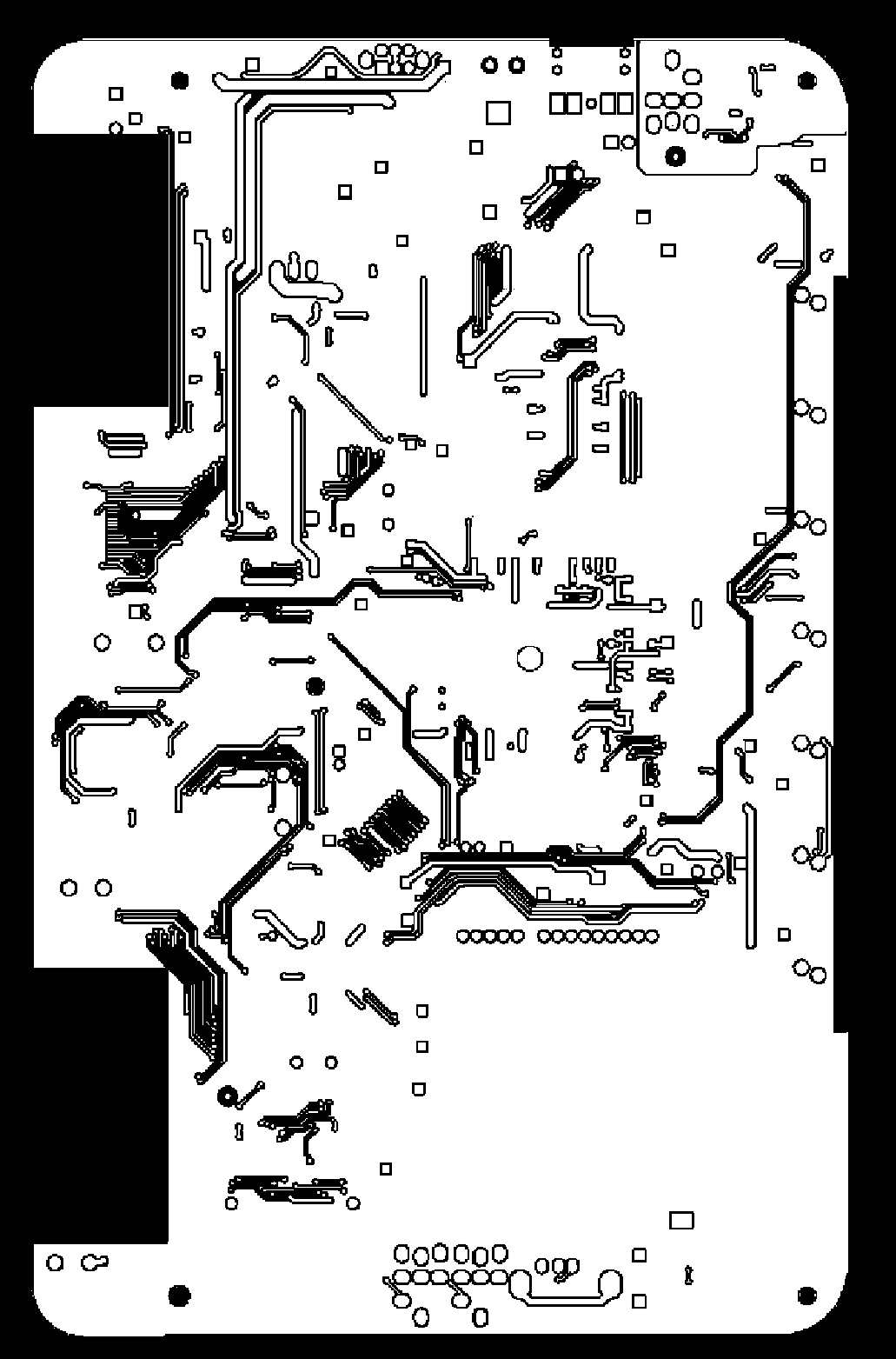

Image

Examples

Embodiment Construction

[0016] The following examples are further explanations and illustrations of the present invention, and do not constitute any limitation to the present invention.

[0017] The manufacturing method of the circuit board of electroplating copper, tin selectively of the present invention (taking double panel as example), the steps are as follows:

[0018] First, drill holes on the cut and baked copper clad board according to the program compiled by the user, and then perform copper sinking or first copper plating on the drilled holes to make the circuits on both sides of the copper clad board conductive. This step is different from the conventional one. The method is similar.

[0019] The gist of the present invention is to selectively electroplate copper and tin on the circuit pattern to replace large-area electroplating copper and tin on the circuit board. The specific steps are:

[0020] 1. Coating a layer of anti-plating covering film on the circuit board after sinking copper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com