LED support

A technology of LED bracket and bracket body, applied in the field of LED bracket, can solve the problems of unstable use, no electroplating layer, inability to maintain electrical continuity between the test head and the pin end, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0018] The invention provides an LED bracket to achieve the purposes of improving product quality and saving costs.

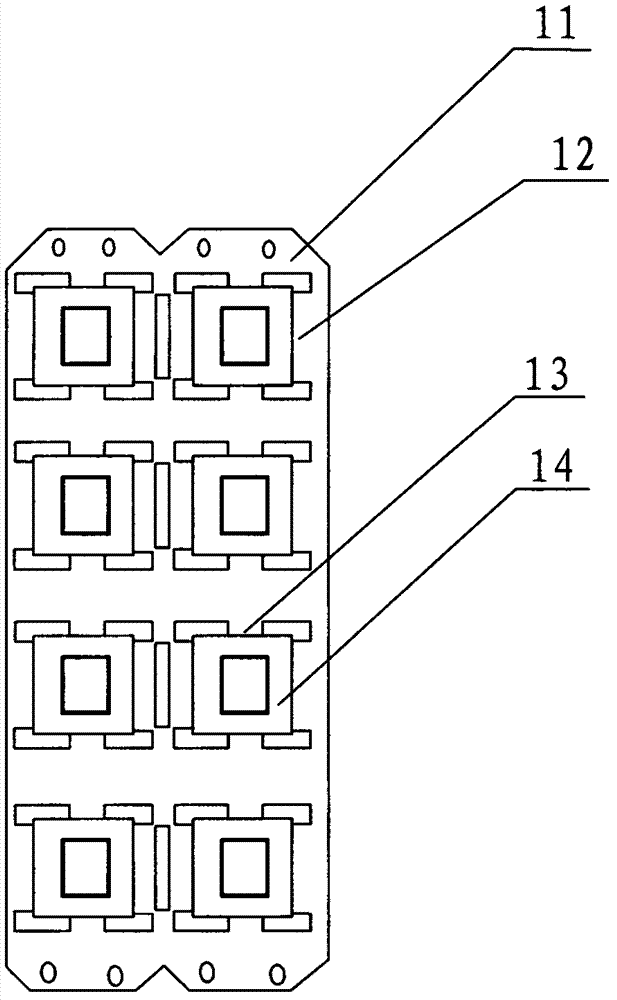

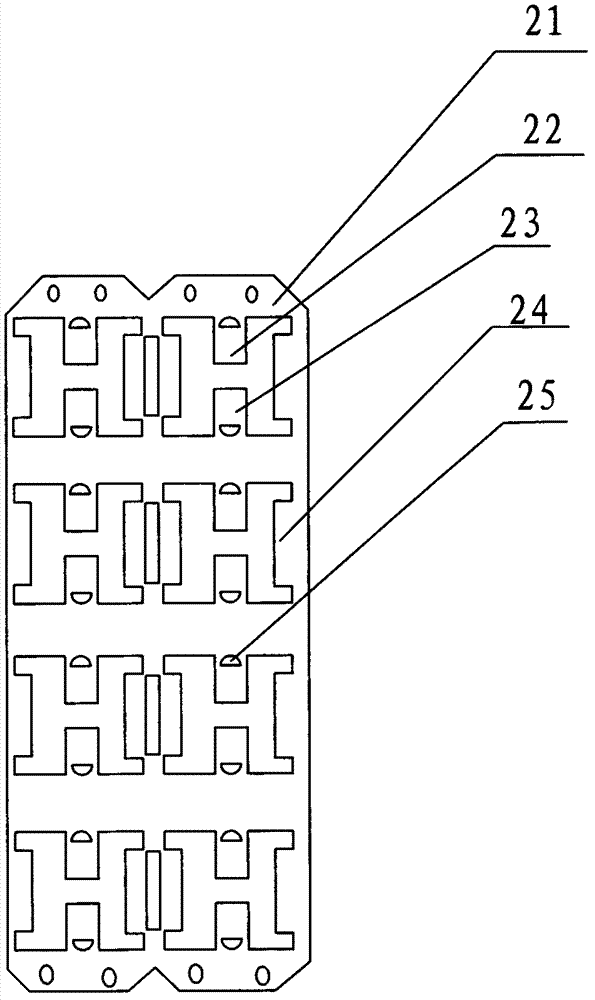

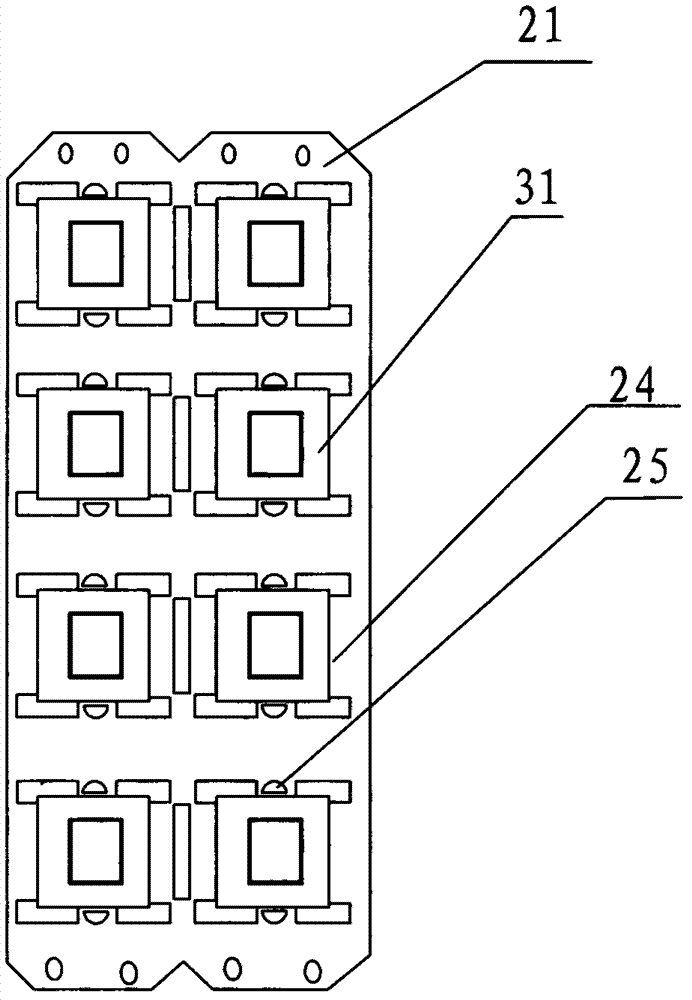

[0019] Such as figure 2 , image 3 As shown, the LED bracket disclosed in the present invention includes a bracket body 21, a plurality of support frames are arranged on the bracket body 21, and pin one 22 and pin two 23 are arranged on each support frame, and the plastic seat 31 is formed on the pin 1 and pin 2, so that one end of pin 1 and pin 2 is exposed inside the plastic seat 31, and the other end passes through the plastic seat to connect with the supporting frame. The pins are combined with the plastic seat to form an LED seat body, and a pair of support pieces 24 are arranged on both sides of the support frame to support the LED seat body.

[0020]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com