Method for improving antifouling property of polyimide film and product

A polyimide membrane, anti-pollution technology, applied in chemical instruments and methods, membrane, membrane technology and other directions, can solve the problems of decreased anti-pollution ability, hydrophilic damage, easy oxidation of bonds, etc., to achieve easy operation, The effect of high hydrophilicity and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

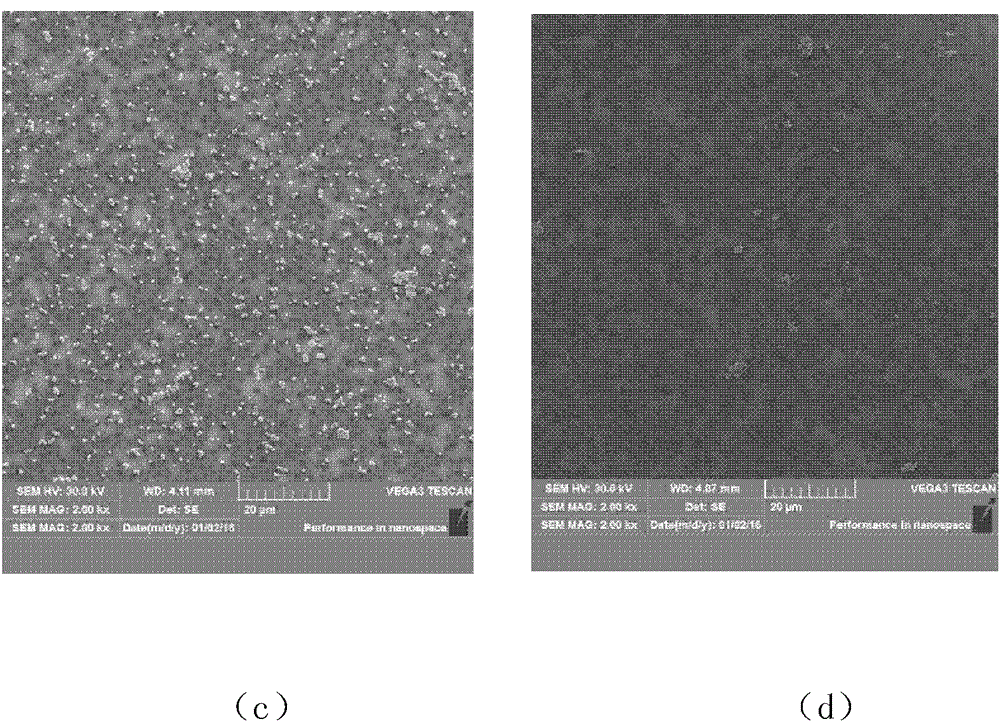

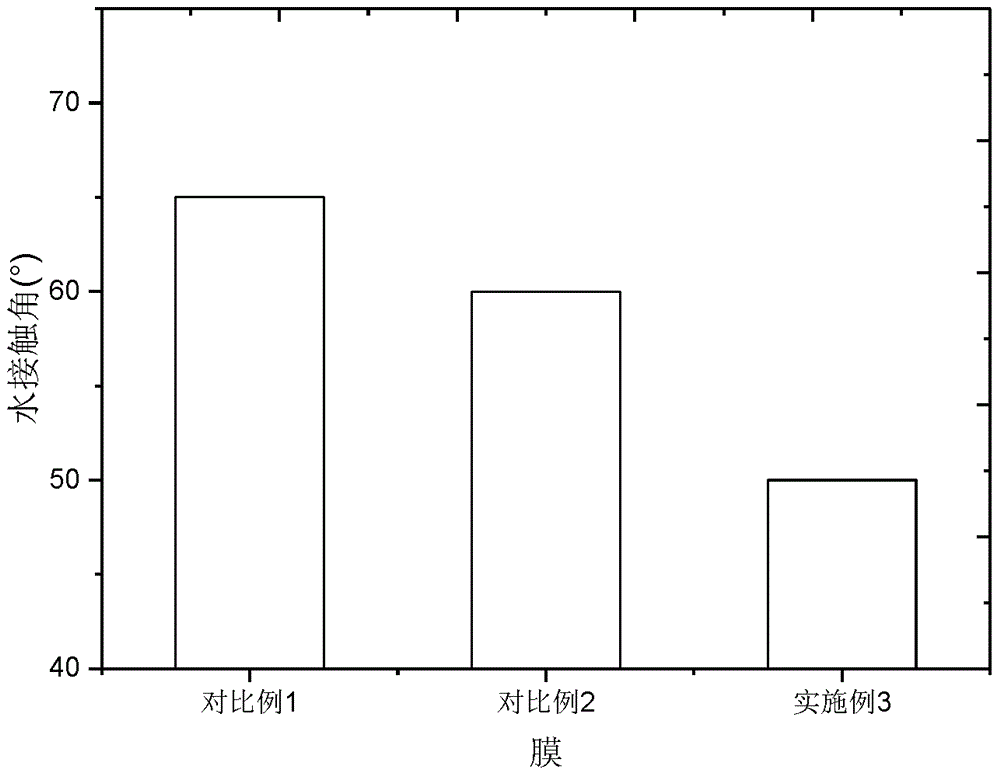

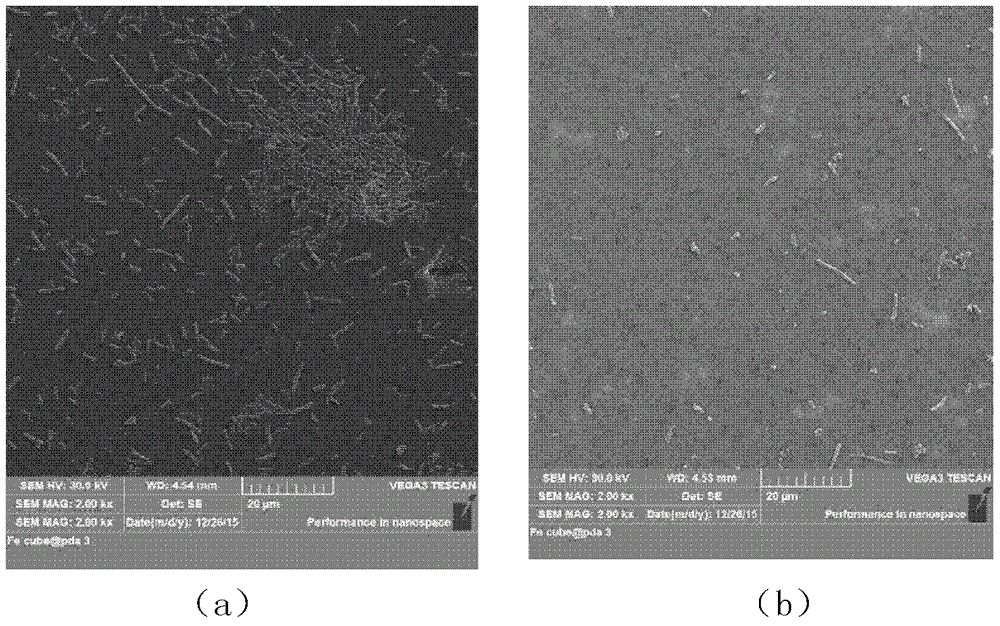

[0028] The method for improving polyimide membrane anti-pollution performance in the present embodiment comprises the following steps:

[0029] S1: Change the model to Immerse the polyimide film in the diamine-containing solution for 30min, then take it out and wash it, and remove the unreacted diamine solution. The diamine solution is N,N-diethylethylenediamine with a concentration of 0.5wt %. The polyimide membrane is a polyimide microfiltration membrane with a pore size of 0.01 μm to 1 μm. The film-forming liquid concentration of the polyimide film was 16%. After soaking, take it out and rinse it with clean water.

[0030] S2 Immerse the polyimide membrane washed in step S1 in a 0.2wt% 1,3-propane sultone solution for 24 hours at a temperature of 50° C., then take it out and wash it to obtain a modified membrane.

Embodiment 2

[0032] The method for improving polyimide membrane anti-pollution performance in the present embodiment comprises the following steps:

[0033] S1: Change the model to The polyimide membrane is immersed in the diamine solution for 60min, and then the unreacted diamine solution is taken out and washed. The diamine solution is N,N-diethylethylenediamine, and the concentration of the diamine solution is 0.5wt%. . The polyimide membrane is a polyimide microfiltration membrane with a pore size of 0.01 μm to 1 μm. The film-forming liquid concentration of the polyimide film was 16%. After soaking, remove and rinse with clean water.

[0034] S2 Immerse the polyimide membrane washed in step S1 in a 0.2wt% 1,3-propane sultone solution for 24 hours at a temperature of 50° C., then take it out and wash it.

Embodiment 3

[0036] The method for improving polyimide membrane anti-pollution performance in the present embodiment comprises the following steps:

[0037] S1: Change the model to The polyimide film is immersed in the diamine solution for 240min, and then the unreacted diamine solution is taken out and washed. The diamine solution is N,N-diethylethylenediamine, and the concentration of the diamine solution is 0.5wt%. . The polyimide membrane is a polyimide microfiltration membrane with a pore size of 0.01 μm to 1 μm. The film-forming liquid concentration of the polyimide film was 16%. After soaking, remove and rinse with clean water.

[0038] S2 Immerse the polyimide membrane washed in step S1 in 0.2wt% 1,3-propane sultone solution for 24 hours at a temperature of 50° C., then take it out and wash it.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com