Farmland residual film recovery machine

A recycling machine and residual film technology, which is applied in the field of agricultural machinery, can solve the problems of reduced value of residual film and the lack of impurity and soil removal mechanism of the model, and achieve the effects of reducing soil entrainment, good effect of crushing soil, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

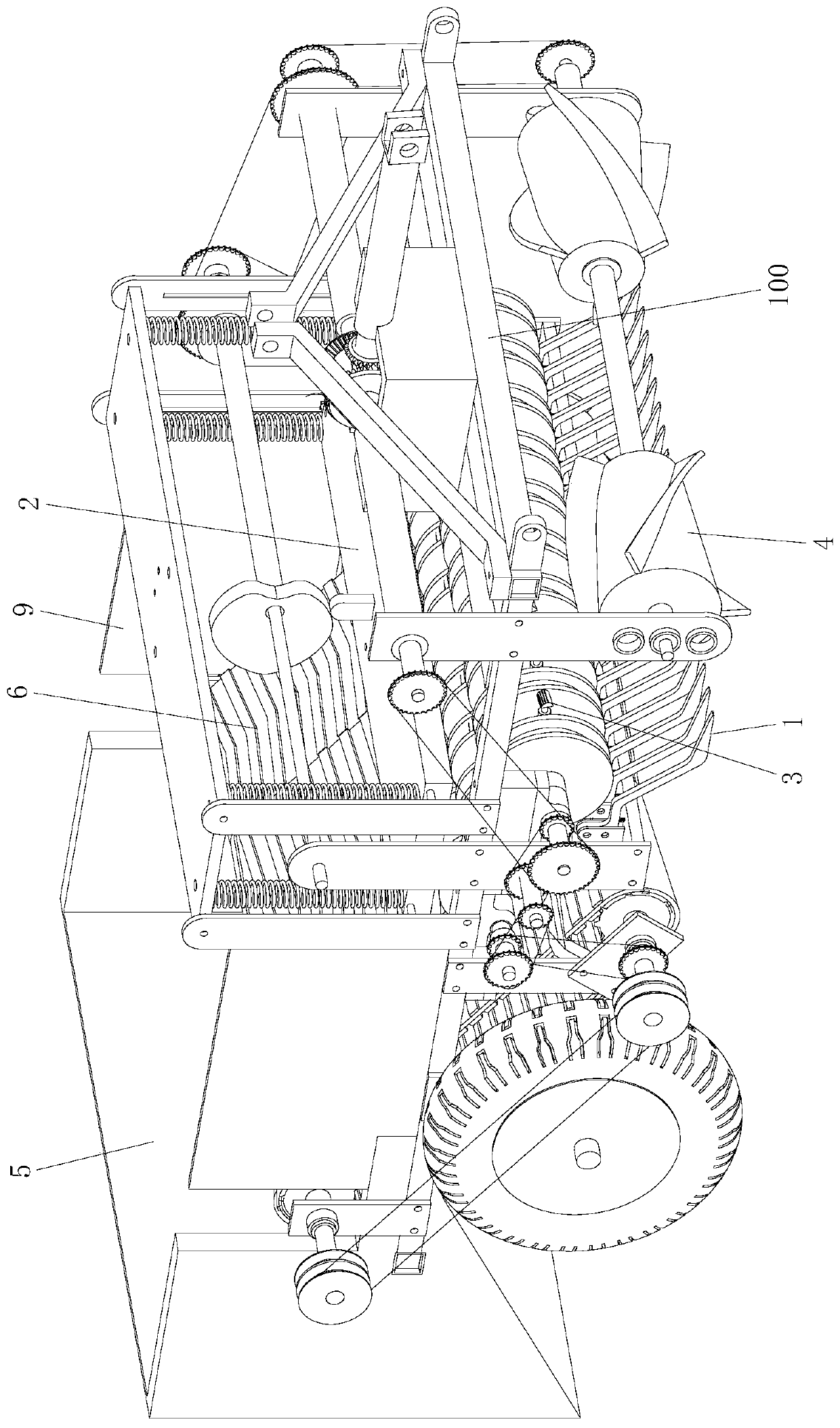

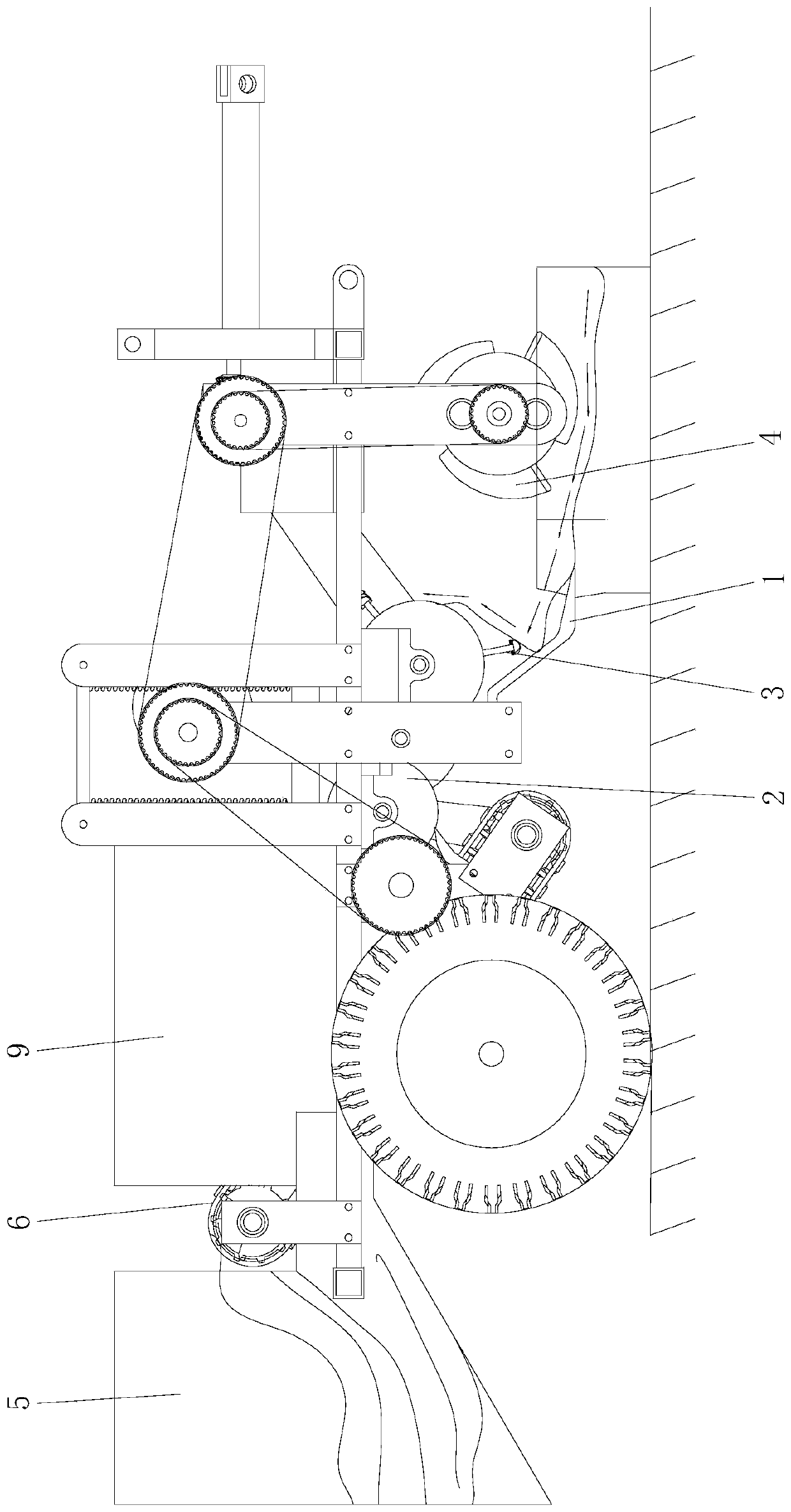

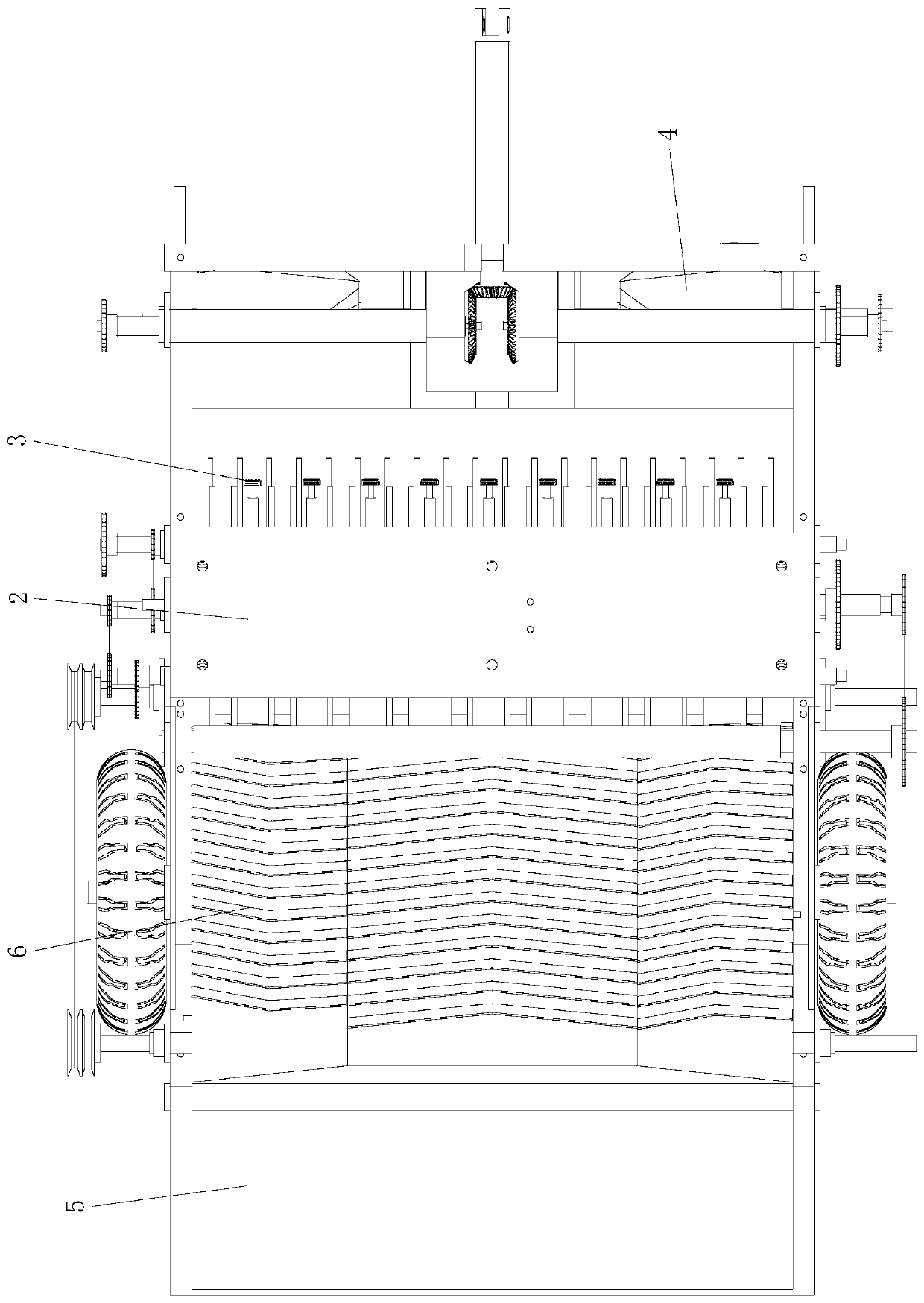

[0034] Such as Figure 1 to Figure 5 As shown, the farmland residual film recovery machine of the present embodiment includes a frame 100, and a plurality of film lifting shovels 1 arranged at intervals successively for stirring the residual film from the soil are installed on the frame 100, for separating the residual film The film-soil separation device 2 for upper soil and the film feeding device 3 for sending the film of the film-soil separation device 2 into the film-soil separation device 2 for the film-shovel 1 to stir up the film-shovel 1. The broken soil device 4 of the soil block on the residual film, the broken soil device 4 comprises the broken soil shaft 41 which is installed on the frame 100 and is driven to rotate by the broken soil drive assembly, and the broken soil shaft 41 is equipped with a corresponding correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com