Powder paint applied to medium-density fiberboard, and preparation method and application thereof

A powder coating, medium density technology, applied in the direction of powder coating, polyester coating, epoxy resin coating, etc., can solve the problems of coating film melting and leveling without time, affecting internal stress, complex curing process, etc., and achieve excellent solvent resistance performance, reduced equipment cost, and simplified curing process

Active Publication Date: 2014-04-09

ANHUI SHENJIAN NEW MATERIALS

View PDF3 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Due to the advantages of environmental protection and economy, powder coatings are widely used on metal surfaces. With the continuous development of powder technology, powder coatings have been successfully applied to wood materials, but because wood materials such as MDF are sensitive to temperature, generally more than 130 -140°C will affect its internal stress, and it is prone to quality problems such as cracking and poor hardness.

Due to the limitations of technology and process, the curing process of powder coatings currently used on MDF is basically mid-infrared curing or UV curing. Since mid-infrared and UV curing processes are very fast curing speeds, the curing time is measured in seconds. Therefore, the coating film does not have enough time to melt and level, so the obtained powder coating coating is basically an art texture such as sand grain, the gloss is about 10%, the coating film is not bright enough, and it is difficult to achieve the surface effect of paint

In addition, due to the complicated curing process of medium density fiberboard, expensive process equipment and unstable process, powder coatings cannot be widely used in medium density fiberboard.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

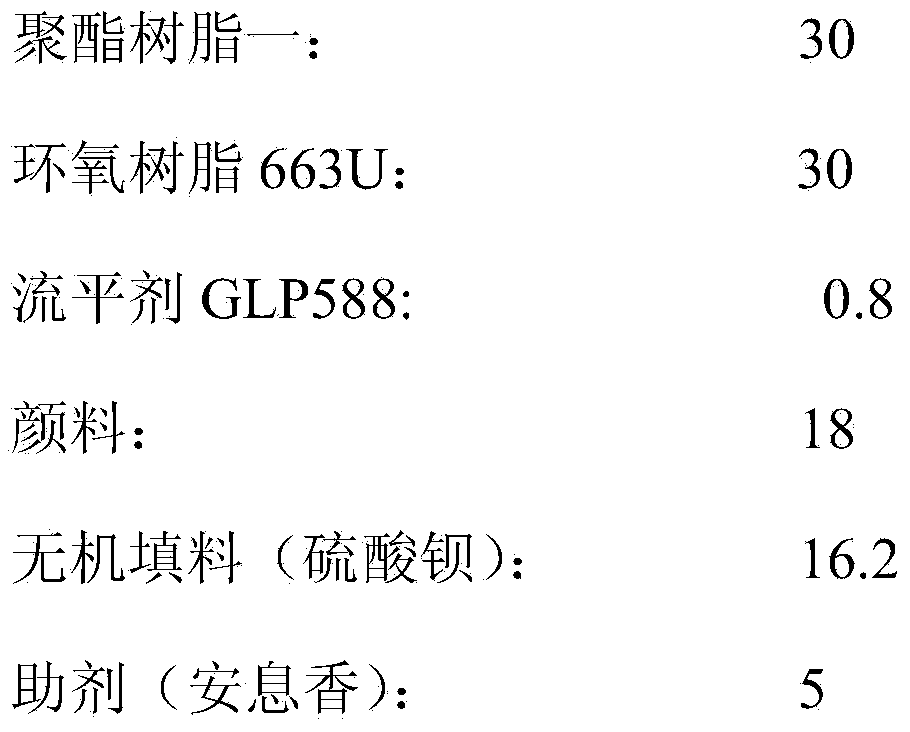

Embodiment 1

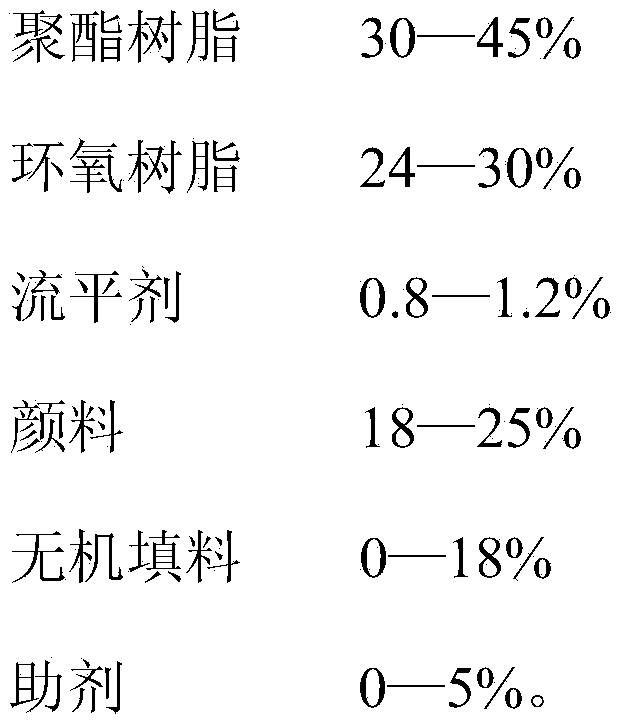

[0018] Present embodiment coating comprises the component of following mass percent:

[0019]

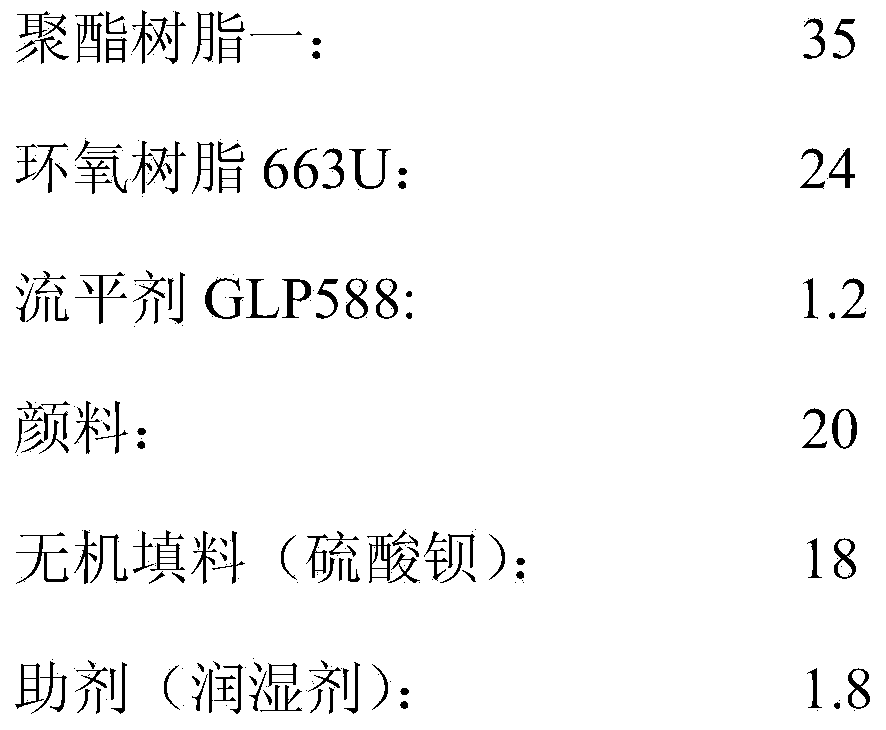

Embodiment 2

[0021] Present embodiment coating comprises the component of following mass percent:

[0022]

Embodiment 3

[0024] Present embodiment coating comprises the component of following mass percent:

[0025]

[0026]

[0027] Present embodiment coating comprises the component of following mass percent:

[0028]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses powder paint applied to a medium-density fiberboard. The paint comprises the following components by weight percent: 30 to 45 percent of polyester resin, 24 to 30 percent of epoxy resin, 0.8 to 1.2 percent of flatting agent, 18 to 25 percent of pigment, 0 to 18 percent of inorganic filler and 0 to 5 percent of accessory ingredient. The invention also discloses a preparation method of the powder paint as well as an application of the powder paint in the medium-density fiberboard. The powder paint is solidified by adopting the conventional hot roasting method, so that the medium-density fiberboard is not damaged; moreover, the powder paint can be sufficiently fused and flatted and can be adequately completely solidified. When the powder paint is applied to the medium-density fiberboard, the glossiness is high, and the coating solvent-resisting property, the moisture resistance, the hardness and the adhesive force are excellent.

Description

technical field [0001] The invention relates to a preparation method of a powder coating, specifically a powder coating applied to medium-density fiberboards. The invention also relates to a preparation method of the powder coating and its application on medium-density fiberboards, belonging to the field of coating industry. Background technique [0002] Due to the advantages of environmental protection and economy, powder coatings are widely used on metal surfaces. With the continuous development of powder technology, powder coatings have been successfully applied to wood materials, but because wood materials such as MDF are sensitive to temperature, generally more than 130 -140°C will affect its internal stress, and it is prone to quality problems such as cracking and poor hardness. Due to the limitations of technology and process, the curing process of powder coatings currently used on MDF is basically mid-infrared curing or UV curing. Since mid-infrared and UV curing pro...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09D167/02C09D163/00C09D5/03C09D7/12C08G63/672C08G63/676

Inventor 刘志坚李保才吴德清汪俊

Owner ANHUI SHENJIAN NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com