Ultraviolet-curable carboxyl alkyl substituted silicone as well as preparation method and application thereof

A carboxyl silicone oil and ultraviolet light technology, applied in the field of ultraviolet light curing, can solve the problems of carboxyl silicone oil not having photocurable properties, easy to be poisoned, complex synthesis, etc., and achieve the effects of high yield, low odor, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

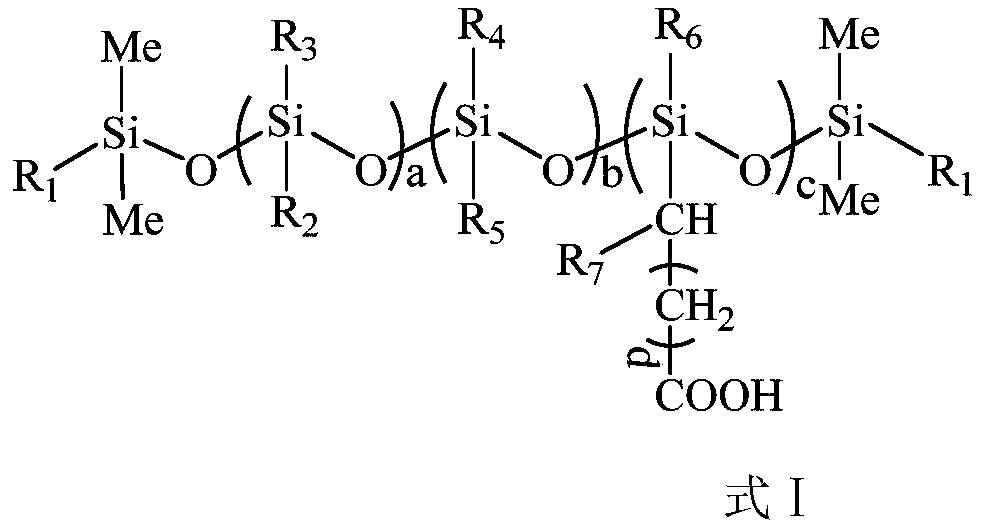

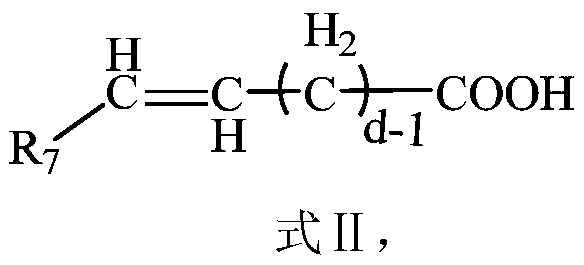

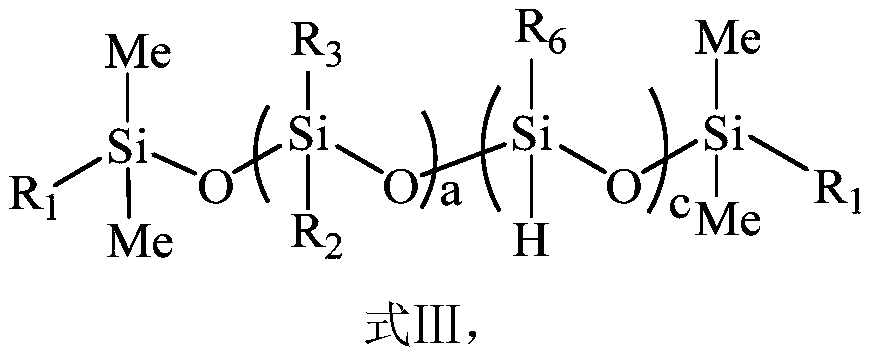

[0072] A kind of UV curable carboxyl silicone oil, its structural formula is:

[0073]

[0074] Its preparation method is:

[0075] Equipped with stirrer, condenser, nitrogen N 2 In the four-neck bottle of the import and thermometer, add undecylenic acid CH 2 =CH(CH 2 ) 8COOH (49.75g, 0.27mol), n-hexane (224.00g), ethanol (60.00g), Dow Corning DC-4000 (0.30g), oxalic acid (1.50g) and hydrogen-containing polysiloxane 100.00g, at 70°C After reacting for 0.5h, after cooling down to 50-60°C, add methacryloxypropylmethyldiethoxysilane (52.08g, 0.20mol), p-hydroxyanisole (0.48g) and concentrated hydrochloric acid ( 2.02g), under vacuum to -0.095~-0.10MPa, react for 2~3h, add end-capping agent MM (1.01g, 0.0062mol), react for 1h, add glacial ethyl acetate (161.46g) , washed 2 times with ice water, took the oil layer, and distilled under reduced pressure for 40min at a vacuum degree of -0.095~-0.10MPa, 80~85°C to obtain a light yellow transparent viscous substance.

[0076] W...

Embodiment 2

[0082] A kind of ultraviolet curable carboxyl silicone oil, its structural formula is:

[0083]

[0084] Its preparation method is:

[0085] Equipped with stirrer, condenser, nitrogen N 2 In the four-necked bottle of the inlet and the thermometer, add acrylic acid CH 2 = CHCOOH (144.12g, 2.00mol), toluene (346.00g), isopropanol (157.30g), ACS-Pt-40 (0.40g), n-hexanoic acid (4.72g) and hydrogen-containing polysiloxane 170.40g, After reacting at 60°C for 1 hour, after cooling down to 50-60°C, add 3-acryloyloxypropylmethyldimethoxysilane (1091.60g, 5.00mol), polymerization inhibitor 701 (0.38g) and three Fluoromethanesulfonic acid (8.44g), under the vacuum degree reaching -0.095~-0.10MPa, after reacting for 2~3h, add methoxytrimethylsilane TMSOME (10.42g, 0.1mol), after reacting for 3h, add After icing toluene (1687.34g), wash it twice with ice water, take the oil layer, and distill it under reduced pressure for 0.5h at a vacuum degree of -0.095~-0.10MPa, 80~85°C to obtain ...

Embodiment 3

[0092] A kind of ultraviolet curable carboxyl silicone oil, its structural formula is:

[0093]

[0094] Its preparation method is:

[0095] Equipped with stirrer, condenser, nitrogen N 2 In the four-necked bottle of the inlet and the thermometer, add 6-heptenoic acid CH 2 =CH(CH 2 ) 4 COOH (61.52g, 0.48mol), heptane (290.80g), methanol (56.50g), CAT-PL-56 (0.23g), phthalic acid (1.30g) and hydrogenated polysiloxane 100.00g, After reacting at 70°C for 0.5h, after cooling down to 50-60°C, add methacryloyloxymethylmethyldiethoxysilane (46.99g, 0.23mol), hydroquinone (11.12g) and concentrated Sulfuric acid (3.75g), at -0.095~-0.10MPa under vacuum, after reacting for 2~3h, add end-capping agent MD 2 M (4.17g, 0.013mol), after reacting for 2h, add icycyclohexane (375.50g), wash twice with ice water, take the oil layer, under vacuum degree of -0.095~-0.10MPa, 80~85℃, Distilled under reduced pressure for 50min to obtain light yellow transparent sticky matter,

[0096] Where...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com