Method for curing lead in fouling acid slag

A technology of polluted acid slag and magnesium slag, applied in the removal of solid waste and other directions, can solve the problems of waste of resources and water pollution of Xiangjiang River, and achieve the effects of low production cost, easy engineering implementation and simple solidification process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

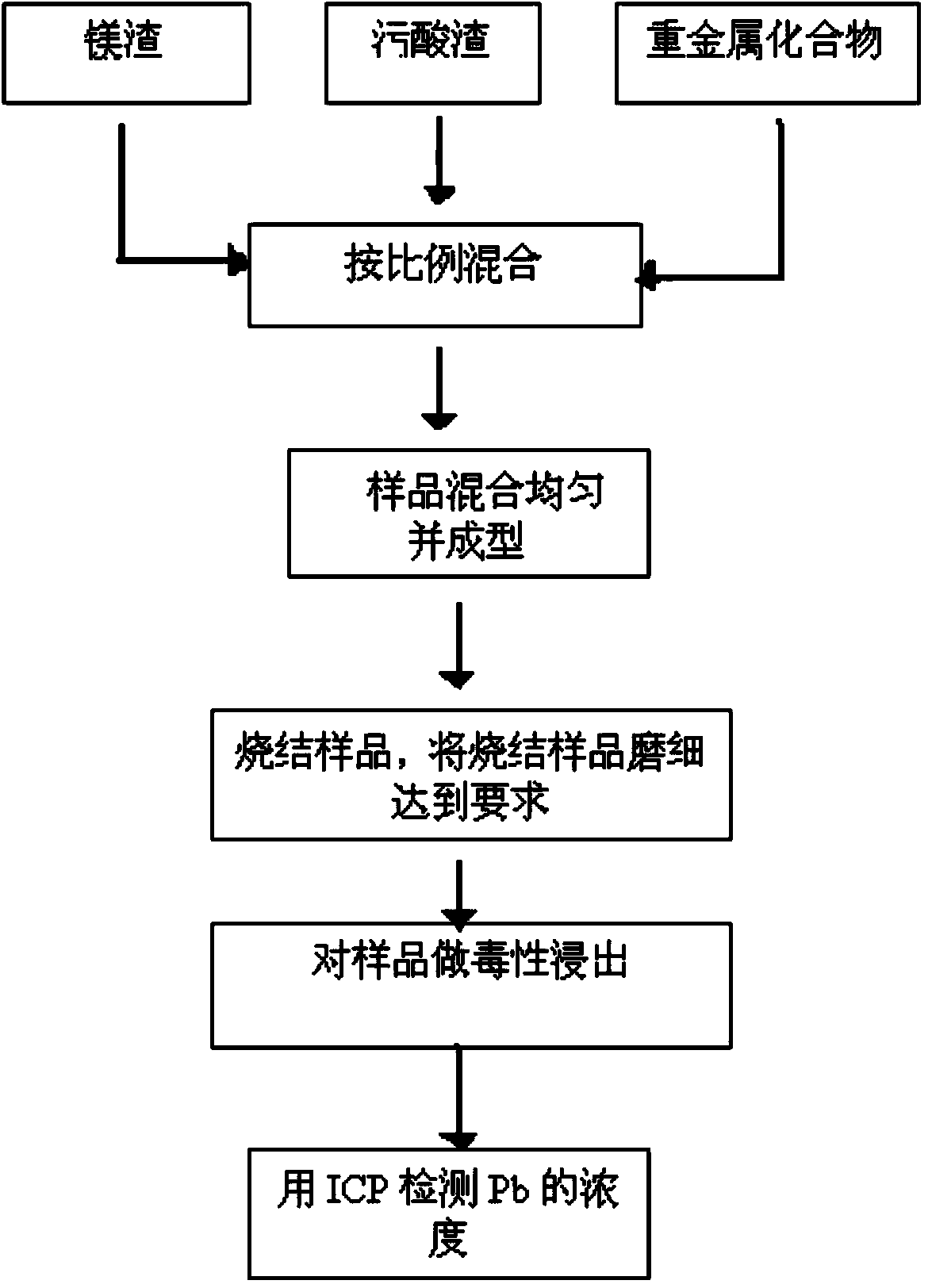

Method used

Image

Examples

Embodiment 1

[0022] The modified (metal) magnesium slag in the following raw materials is the magnesium smelting slag of Ningxia Huiye Magnesium Industry Group Co., Ltd., and the polluted acid slag is the slag of the lead-zinc smelting enterprise (Zhuzhou Smelting Group Co., Ltd.).

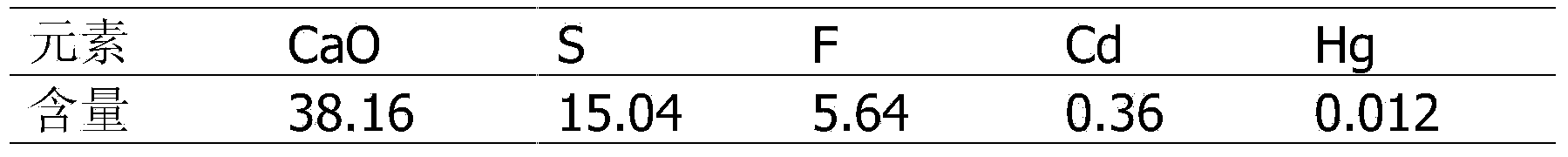

[0023] Chemical composition of polluted acid slag (%)

[0024]

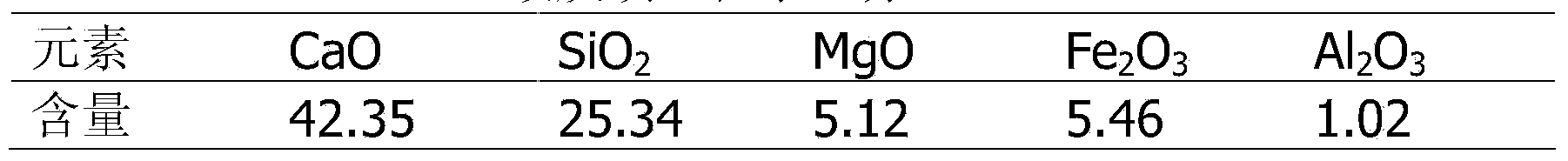

[0025] Chemical composition of modified magnesium slag (%)

[0026]

[0027] First, use the jaw crusher model HF-ZY-EPX to crush the polluted acid slag and modified magnesium slag, put them into the sealed sample preparation grinder model HFZY-B3 for dry grinding, and grind them to a particle size of 40 Mesh, and then fully mixed the modified magnesium slag and the dirty acid slag in a weight ratio of 6:4 to obtain a mixture with a total mass of 5Kg.

[0028] Add Pb(NO 3 ) 2 Mix the saturated solution of Pb so that the mass fraction of Pb in the mixture reaches 1%.

[0029] Then bake at 105°C for 24 hours, and use a universal hydraulic ...

Embodiment 2

[0032] The dirty acid slag and magnesium slag are mechanically ground to a particle size below 40 mesh; the magnesium slag and the dirty acid slag are mixed in a weight ratio of 6:4, and a mixture with a total mass of 5Kg is prepared. A certain amount of Pb(NO 3 ) 2 The saturated solutions were mixed to achieve a Pb content of 0.48% in the mixed sample. Dry at 105°C and press into shape. Sinter at a temperature of 900°C, hold for 2 hours, and cool naturally. The solidified polluted acid slag can be processed as a resource.

[0033] According to GB5085.3-2007 and HJ / T299-2007, the leaching results are: before curing, the leaching result of Pb is ≥6.02 mg / L, and after curing, the Pb is 0.005 mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com