Ultraviolet curing adhesive as well as preparation method and application thereof

An ultraviolet light, curing glue technology, applied in the direction of adhesives, adhesive additives, adhesive types, etc., can solve the problems of high cost, narrow application area, difficult surface roughness, etc., to achieve fast curing speed and good reliability. , Dispensing convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

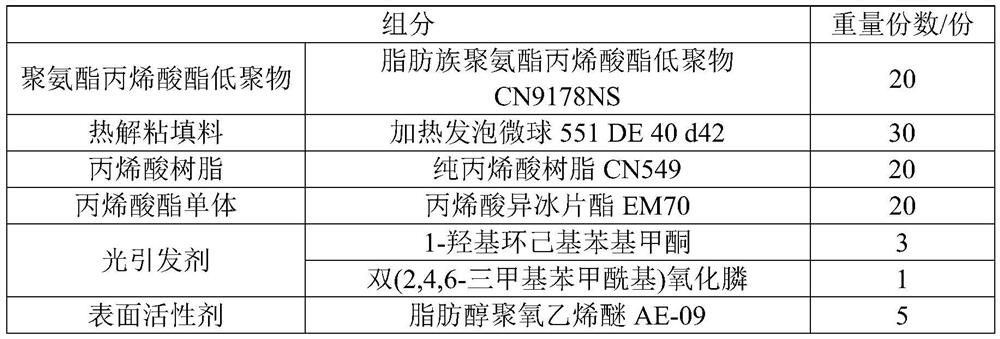

[0055] This embodiment provides a UV-curable adhesive, and the UV-curable adhesive includes the following components in parts by weight:

[0056]

[0057]

[0058] The preparation method of the ultraviolet light curing adhesive described in this embodiment comprises the following steps:

[0059] (1) Mix and stir the urethane acrylate oligomer, acrylic resin and acrylic monomer at 25° C. at a speed of 100 rpm for 15 minutes to obtain the first mixture;

[0060] (2) Mix and stir the first mixture, photoinitiator and antioxidant obtained in step (1) at a speed of 110 rpm for 30 min at 25° C. to obtain a second mixture;

[0061] (3) The second mixture obtained in step (2), thermal debonding filler, surfactant, leveling agent and dispersant were mixed and stirred at 130 rpm for 30 minutes at 25°C, and then filtered at 200 meshes to obtain the UV curable adhesive.

Embodiment 2

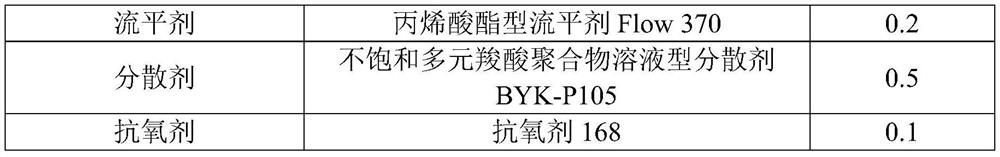

[0063] This embodiment provides a UV-curable adhesive, and the UV-curable adhesive includes the following components in parts by weight:

[0064]

[0065] The preparation method of the ultraviolet light curing adhesive described in this embodiment comprises the following steps:

[0066] (1) Mix and stir the urethane acrylate oligomer, acrylic resin and acrylic monomer at 20° C. at a speed of 100 rpm for 15 minutes to obtain the first mixture;

[0067] (2) Mix and stir the first mixture, photoinitiator and antioxidant obtained in step (1) at a speed of 110 rpm for 30 min at 20° C. to obtain a second mixture;

[0068] (3) The second mixture obtained in step (2), thermal debonding filler, surfactant, leveling agent and dispersant were mixed and stirred at 130 rpm for 30 minutes at 20°C, and then filtered at 300 meshes to obtain the UV curable adhesive.

Embodiment 3

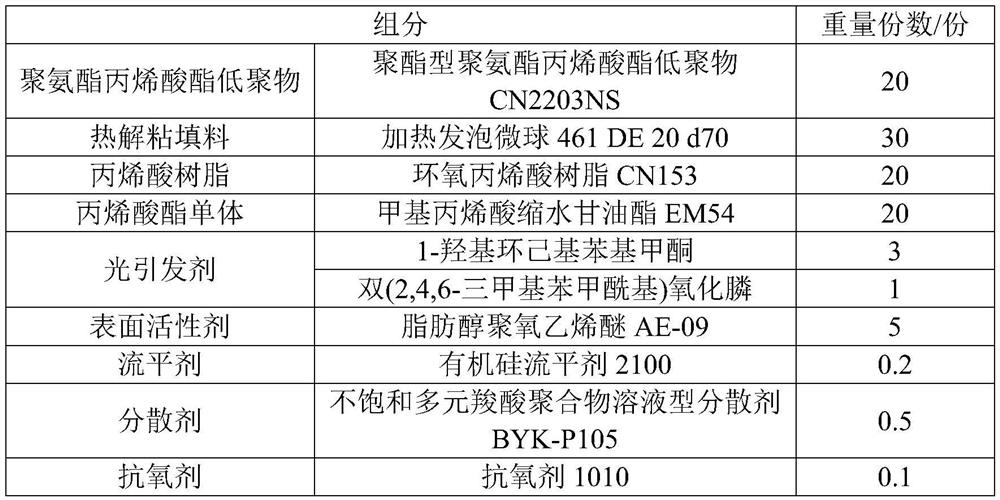

[0070] This embodiment provides a UV-curable adhesive, and the UV-curable adhesive includes the following components in parts by weight:

[0071]

[0072] The preparation method of the UV-curable adhesive described in this example is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com