Photo-cured polyurethane anti-fog film with controllable soft/hard structure and preparation method thereof

A technology of polyurethane and polyurethane prepolymer, which is applied in the field of light-curable soft and hard structure controllable polyurethane anti-fog film and its preparation, which can solve the problems of complex production process, short anti-fog persistence, fogging, etc. Achieve the effects of mature synthesis technology, excellent anti-fog effect, and flexible curing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

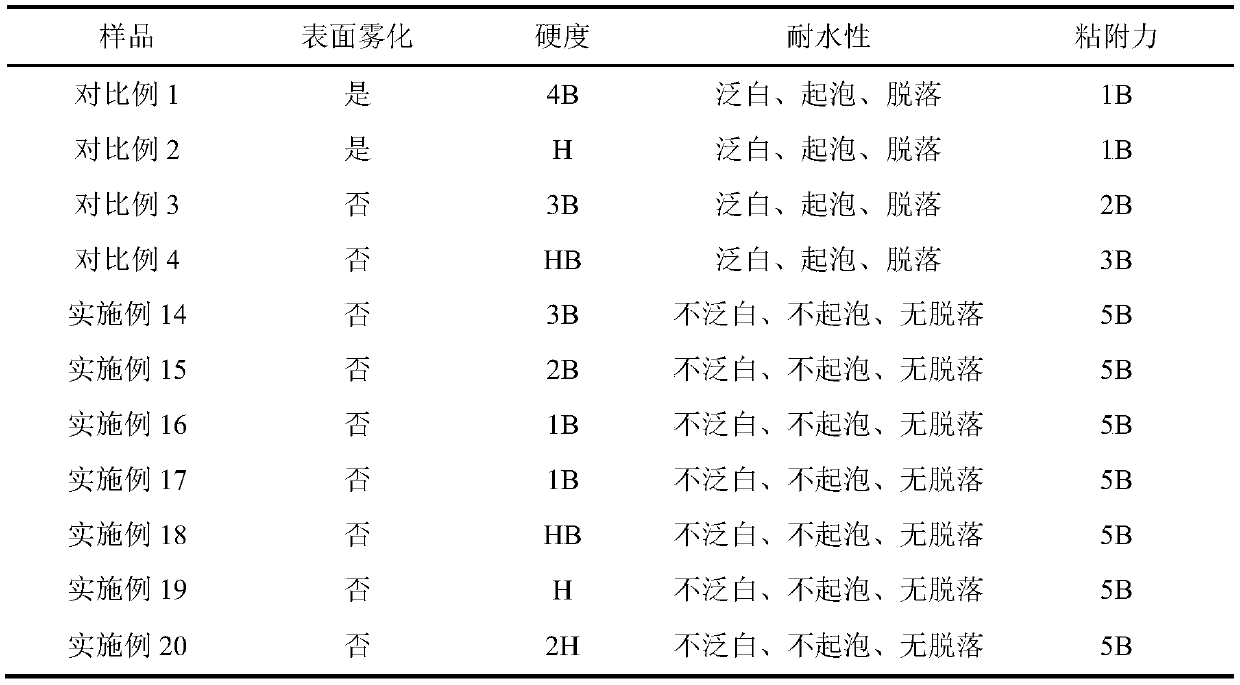

Examples

Embodiment 1

[0031] Put 100 parts of isophorone diisocyanate in a flask, add an appropriate amount of acetone to dissolve, put 10 parts of dehydrated polyethylene glycol 200 in a constant pressure dropping funnel, pass nitrogen to remove oxygen, and use dibutyltin dilaurate as a catalyst Under the action, raise the temperature to 50°C and stir mechanically, and react for 1h; then add 10 parts of hydroxyethyl acrylate and 80 parts of OP-10, stir and react at 60°C for 2h, stop the heating reaction, and get Soft Structure Polyurethane Prepolymer 1 .

Embodiment 2

[0033] Put 100 parts of isophorone diisocyanate in a flask, add an appropriate amount of acetone to dissolve, put 10 parts of dehydrated polyethylene glycol 200 in a constant pressure dropping funnel, pass nitrogen to remove oxygen, and use dibutyltin dilaurate as a catalyst Under the action, raise the temperature to 50°C and stir mechanically, and react for 1 hour; then add 45 parts of hydroxyethyl acrylate and 45 parts of Triton X-100, stir and react at 60°C for 2 hours, stop the heating reaction, and obtain Soft structure polyurethane prepolymer 2 .

Embodiment 3

[0035] Put 100 parts of isophorone diisocyanate in a flask, add an appropriate amount of acetone to dissolve, put 10 parts of dehydrated polyethylene glycol 200 in a constant pressure dropping funnel, pass nitrogen to remove oxygen, and use dibutyltin dilaurate as a catalyst Under the action, raise the temperature to 50°C and stir mechanically, and react for 1 hour; then add 80 parts of hydroxyethyl acrylate and 10 parts of Triton X-114, stir and react at 60°C for 2 hours, stop the heating reaction, and obtain Soft structure polyurethane prepolymer 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com