Pollutional acid sludge harmless treatment method

A harmless treatment and technology of polluted acid slag, applied in the field of environmental protection, can solve the problems of polluted acid slag polluting the environment and achieve low cost, obvious economic and environmental benefits, and easy project implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

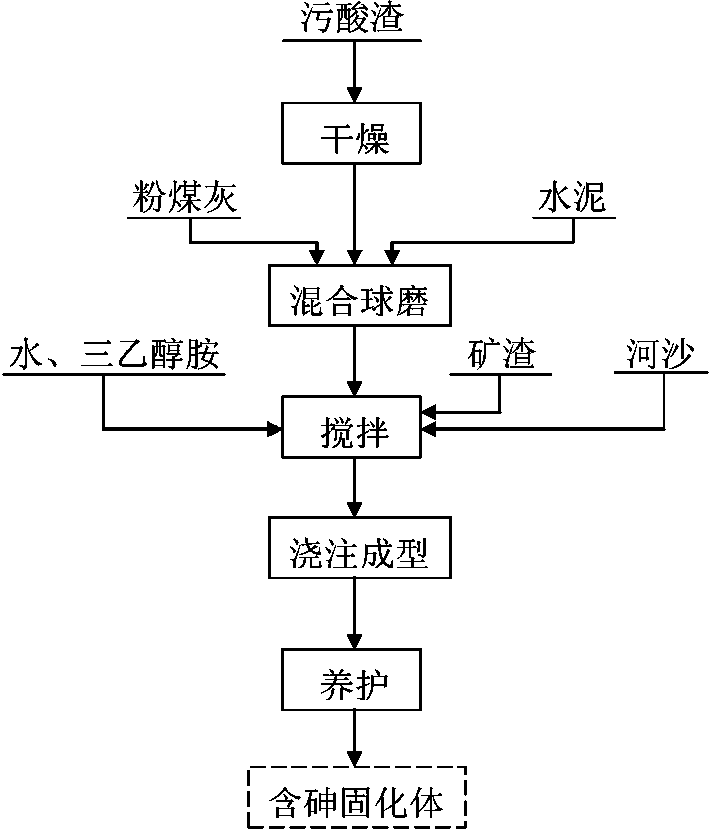

Image

Examples

Embodiment 1

[0021] Step 1. Drying: Put the dirty acid residue in an oven for drying, and the temperature is controlled at 50°C;

[0022] Step 2: Ball milling: Ball mill the fly ash for 10 minutes in advance, and then mix it with the dirty acid slag and ordinary Portland cement for 15 minutes. The addition amount of ordinary Portland cement and fly ash is 50% of the quality of the dirty acid slag. And 20%;

[0023] Step 3. Stirring: Add the ball-milled materials to the mixer, add river sand and slag to it, slowly add water and stir, add the additive triethanolamine while adding water, stir for 10 minutes, control the water ratio to 0.3, and the amount of river sand and slag added Both are 10% of the quality of dirty acid residue, and the added amount of triethanolamine is 0.03% of the quality of dirty acid residue;

[0024] Step 4. Pouring and forming: Put the mixed materials into the standard brick mold, and release the mold after holding the pressure with a press to obtain a brick-shaped solid...

Embodiment 2

[0028] Step 1. Drying: Put the dirty acid residue in an oven for drying, and the temperature is controlled at 60°C;

[0029] Step 2: Ball milling: Ball mill the fly ash for 10 minutes in advance, then mix it with the dirty acid slag and ordinary Portland cement for 20 minutes, and control the addition of ordinary Portland cement and fly ash to 50% of the quality of the dirty acid slag. And 30%;

[0030] Step 3. Stirring: Add the ball-milled materials to the mixer, add river sand and slag to it, slowly add water and stir, add the additive triethanolamine while adding water, stir for 10 minutes, control the moisture ratio to 0.4, and the amount of river sand and slag added It is 20% and 10% of the quality of dirty acid residue, and the added amount of triethanolamine is 0.04% of the quality of dirty acid residue;

[0031] Step 4. Pouring and forming: Put the mixed materials into the standard brick mold, and release the mold after holding the pressure with a press to obtain a brick-sha...

Embodiment 3

[0035] Step 1. Drying: Put the dirty acid residue in an oven for drying, and the temperature is controlled at 60°C;

[0036] Step 2: Ball milling: Ball mill the fly ash for 15 minutes in advance, then mix it with the dirty acid slag and ordinary Portland cement for 20 minutes, and control the addition of ordinary Portland cement and fly ash to 40% of the quality of the dirty acid slag. And 20%;

[0037] Step 3. Stirring: Add the ball-milled material to the mixer, add river sand and slag to it, slowly add water and stir, add the additive triethanolamine while adding water, stir for 15 minutes, control the moisture ratio of 0.4, the amount of river sand and slag added Both are 20% of the quality of dirty acid residue, and the added amount of triethanolamine is 0.05% of the quality of dirty acid residue;

[0038] Step 4. Pouring and forming: Put the mixed materials into the standard brick mold, and release the mold after holding the pressure with a press to obtain a brick-shaped solidi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com