Epoxy-resin-based conductive adhesive and preparation method thereof

A technology of epoxy resin and conductive adhesive, applied in epoxy resin adhesive, conductive adhesive, adhesive and other directions, can solve the problem that there is no research on the conductive properties of epoxy resin-based composite materials, the conductive properties of composite materials are not significantly improved, and the raw material silver powder Expensive electrical conductivity and other issues, to achieve the effect of improving interface compatibility, simple curing method and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Ingredients

[0035] In this embodiment, the raw materials of epoxy resin-based conductive adhesive are composed as follows in parts by mass:

[0036] 10 parts of bisphenol A epoxy resin, 0.6 parts of micron iron powder (average particle size 5.5 microns), 1.2 parts of curing agent diethylenetriamine, accelerator 2,4,6-tri-(dimethylaminomethyl) 0.2 parts of phenol, 1 part of toughening agent dioctyl phthalate, 0.6 parts of coupling agent KH560.

[0037] 2. Preparation

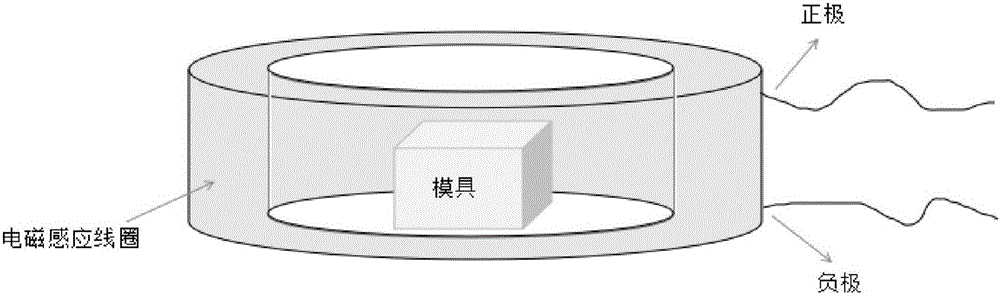

[0038] (1) Modification of micron iron powder

[0039] Using absolute ethanol as the reaction medium, add a coupling agent to the micron iron powder, mix well and then stir and react at 60°C for 4 hours; after the reaction is completed, cool to room temperature, filter and dry at 100°C for 2 hours to obtain the modified Sexual micron iron powder;

[0040] (2) Preparation of composite materials

[0041] Heat the epoxy resin to 60°C, add the toughening agent, stir and react for 1 hour, then add the...

Embodiment 2

[0053] 1. Ingredients

[0054] In this embodiment, the raw materials of epoxy resin-based conductive adhesive are composed as follows in parts by mass:

[0055] 10 parts of bisphenol A epoxy resin, 2 parts of micron iron powder (average particle size 3.4 microns), 1.2 parts of curing agent diethylenetriamine, accelerator 2,4,6-tri-(dimethylaminomethyl) 0.2 parts of phenol, 1 part of toughening agent dioctyl phthalate, 2 parts of coupling agent KH560.

[0056] 2. Preparation

[0057] (1) Modification of micron iron powder

[0058] Using absolute ethanol as the reaction medium, add a coupling agent to the micron iron powder, mix well and then stir and react at 60°C for 4 hours; after the reaction is completed, cool to room temperature, filter and dry at 100°C for 2 hours to obtain the modified Sexual micron iron powder;

[0059] (2) Preparation of composite materials

[0060] Heat the epoxy resin to 60°C, add the toughening agent, stir and react for 1 hour, then add the mod...

Embodiment 3

[0072] 1. Ingredients

[0073] In this embodiment, the raw materials of epoxy resin-based conductive adhesive are composed as follows in parts by mass:

[0074] 10 parts of bisphenol A epoxy resin, 4.8 parts of micron iron powder (average particle size 8 microns), 1.2 parts of curing agent diethylenetriamine, accelerator 2,4,6-tri-(dimethylaminomethyl) 0.2 parts of phenol, 1 part of toughening agent dioctyl phthalate, 4.8 parts of coupling agent KH560.

[0075] 2. Preparation

[0076] (1) Modification of micron iron powder

[0077] Using absolute ethanol as the reaction medium, add a coupling agent to the micron iron powder, mix well and then stir and react at 60°C for 4 hours; after the reaction is completed, cool to room temperature, filter and dry at 100°C for 2 hours to obtain the modified Sexual micron iron powder.

[0078] (2) Preparation of composite materials

[0079] Heat the epoxy resin to 60°C, add the toughening agent, stir and react for 1 hour, then add the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com