Moisture-curable polyurethane hot melt adhesive, preparation method and application thereof, and steel member

A polyurethane hot-melt adhesive and hot-melt adhesive technology, applied in the field of polyurethane hot-melt adhesive, can solve the problems of steel structure building leakage, affect the service life of the building, and cannot solve the problems of steel structure building leakage, etc., and achieve high and low temperature resistance, The effect of long service life and high bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

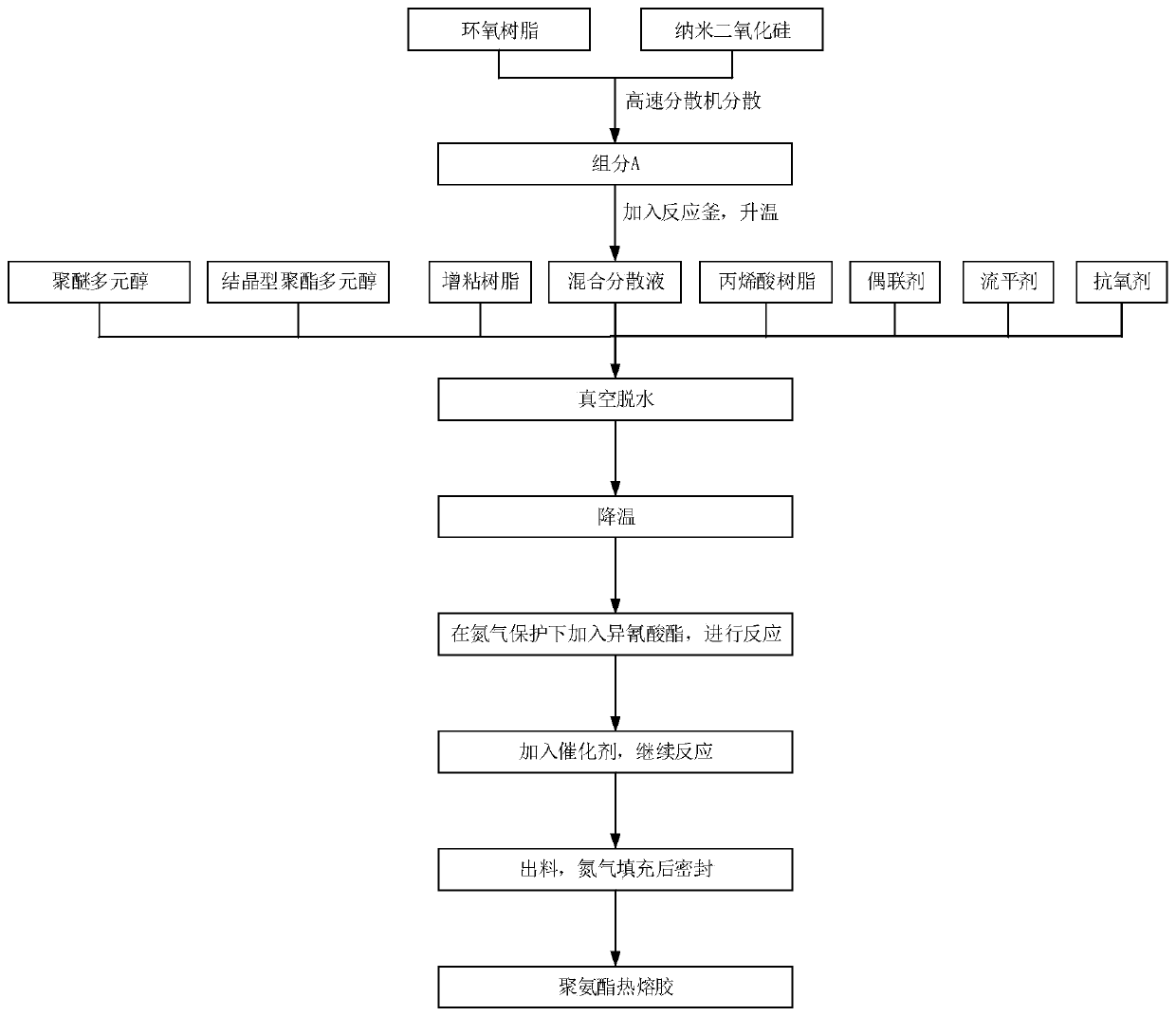

[0034] further, see figure 1, the invention provides a method for preparing polyurethane hot melt adhesive, comprising: mixing and dispersing nano silicon dioxide and epoxy resin; heating; adding polyether polyol, crystalline polyester polyol, tackifying resin, acrylic acid Resin, coupling agent, leveling agent and antioxidant, and vacuum dehydration; cooling; adding isocyanate under the protection of nitrogen to react; adding catalyst to continue the reaction; and discharge, nitrogen filling and sealing to obtain polyurethane hot melt adhesive .

[0035] Specifically, the epoxy resin is first placed under a high-speed disperser, and nano-silica is added to disperse at high speed to prepare component A. Finally, the temperature of the reactor is raised to 130°C to form a mixed dispersion; add component A, polyether polyol, crystalline polyester polyol, tackifier resin, acrylic resin, coupling agent, leveling agent and antioxidant, After vacuum dehydration for 3 hours, cool d...

Embodiment 1

[0041] First place 40 parts of EP-16 (epoxy resin) under a high-speed disperser, add 5 parts of R 974 (nano silicon dioxide) and disperse at high speed to prepare component A. Finally, the temperature of the reactor was raised to 130°C, and Component A, 40 parts of PPG2000 (polyether polyol), 20 parts of Dynacoll 7360 (crystalline polyester polyol), 25 parts of Elvacite2013 (acrylic resin), and 25 parts of Vestoplast508 (tackifying resin) were added. ) 5 parts, KH 550 (coupling agent) 1 part, antioxidant 1010 0.1 part and leveling agent 0.1 part, after vacuum dehydration for 3 hours, cool down to 90 ℃ ~ 110 ℃, add MDI (isocyanate) 13 under nitrogen protection Parts, react at 110°C for 1 to 2 hours, until the NCO% content of the reaction product reaches the theoretical value (about 1.5%), add 0.1 part of DMDEE (amine catalyst), and stop the reaction after 10 to 20 minutes of reaction. The material is discharged into an aluminum foil bag, filled with nitrogen and sealed to obtai...

Embodiment 2

[0043] The difference between embodiment 2 and embodiment 1 is to adjust the consumption of each raw material, namely:

[0044] 40 parts of EP-16 (epoxy resin);

[0045] 5 parts of R 974 (nanometer silicon dioxide);

[0046] 60 parts of PPG 2000 (polyether polyol);

[0047] Dynacoll 7360 (crystalline polyester polyol) 20 parts;

[0048] Elvacite 2013 (acrylic resin) 25 parts;

[0049] 5 parts of Vestoplast 508 (tackifying resin);

[0050] 1 part of KH 550 (coupling agent);

[0051] Antioxidant 1010 0.1 part;

[0052] Leveling agent 0.1 part;

[0053] 13 parts of MDI (isocyanate);

[0054] DMDEE (amine catalyst) 0.1 part.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com