Arsenic-containing waste slag solidified body and preparation method thereof

A technology for solidified body and waste residue is applied in the field of arsenic-containing waste residue solidified body and its preparation, which can solve the problems of environmental pollution and comprehensive utilization of arsenic-containing waste residue, and achieve the effects of easy environmental protection compliance, simple process, and easy engineering implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

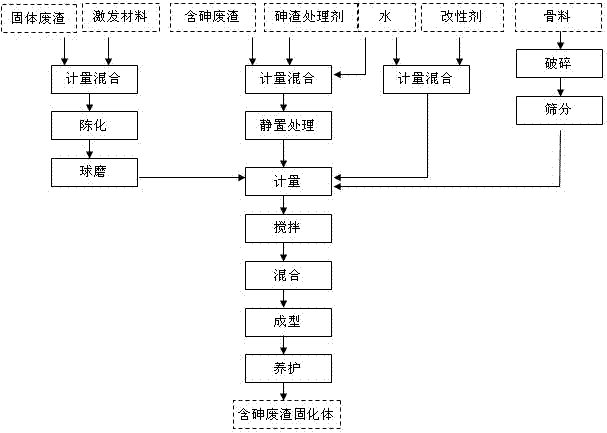

Image

Examples

Embodiment 1

[0033] Example 1: The arsenic-containing waste slag solidified body is composed of arsenic-containing waste slag, curing agent, arsenic slag treatment agent, modifier, aggregate and water. smelting dust), 300 parts of curing agent (50 parts of blast furnace slag, 20 parts of fly ash, 10 parts of steel slag, 20 parts of tin metallurgical slag, 50 parts of lime, 150 parts of clinker), 10 parts of arsenic slag treatment agent (silicon 1 part of ash, 1 part of superfine fly ash, 5.4 parts of carbide slag, 1 part of kiln dust, 0.5 part of iron sulfate, 0.2 part of aluminum sulfate, 0.3 part of sodium phosphate, 0.2 part of borate, 0.4 part of sodium sulfate), modified 5 parts of agent (0.8 parts of polycarboxylic acid, 0.2 parts of humic acid, 2 parts of styrene-acrylic emulsion, 1 part of vinyl acetate emulsion, 1 part of silicon-acrylic emulsion), 600 parts of phosphorus slag aggregate.

[0034] The preparation method of the arsenic-containing waste slag solidified body is as fo...

Embodiment 2

[0046] Example 2: The arsenic-containing waste slag solidified body is composed of arsenic-containing waste slag, curing agent, arsenic slag treatment agent, modifier, aggregate and water. 90 parts of smelting dust removal dust, 10 parts of arsenic iron slag containing 2.0% arsenic), 45 parts of curing agent (22 parts of fly ash, 2 parts of calcined coal gangue, 2 parts of calcined clay, 2 parts of calcined red mud, 2 parts of copper slag 30 parts in total, 15 parts of clinker), 60 parts of arsenic slag treatment agent (4 parts of silica fume, 5 parts of superfine fly ash, 30 parts of kiln dust, 10 parts of white mud for papermaking, 5 parts of calcium carbonate, 5 parts of dolomite , 1 part of iron sulfate), 0.5 part of modifier (0.2 part of polycarboxylic acid, 0.3 part of styrene-acrylic emulsion), 30 parts of quartz sand aggregate.

[0047] The preparation method of the arsenic-containing waste slag solidified body is as follows:

[0048] 1. Raw material processing

[...

Embodiment 3

[0059] Example 3: The solidified body of arsenic-containing waste slag is composed of arsenic-containing waste slag, curing agent, arsenic slag treatment agent, modifier, aggregate and water. 80 parts of zinc smelting dust, 20 parts of desulfurized gypsum containing 15% arsenic), 110 parts of curing agent (5 parts of blast furnace slag, 43 parts of phosphorus slag, 30 parts of lime, 32 parts of clinker), 30 parts of arsenic slag treatment agent (5 parts of silica fume, 4.5 parts of caustic soda, 20 parts of sodium silicate, 0.3 parts of sodium phosphate, 0.2 parts of borate), 2.5 parts of styrene-acrylic emulsion modifier, 315 parts of lead-zinc metallurgical waste residue aggregate.

[0060] The preparation method of the arsenic-containing waste slag solidified body is as follows:

[0061] 1. Raw material processing

[0062] 1) Treatment of arsenic-containing waste residues (substances are measured in parts by mass):

[0063] Take 80 parts of lead-zinc smelting dust remov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com