Light-curing preparation method of rare earth bonded fluorescent gel glass

A gel glass and light-curing technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of low luminous efficiency of materials, uneven dispersion of rare earth elements, etc., achieve high rare earth doping concentration, short reaction time, and improve Effect of Fluorescence Intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

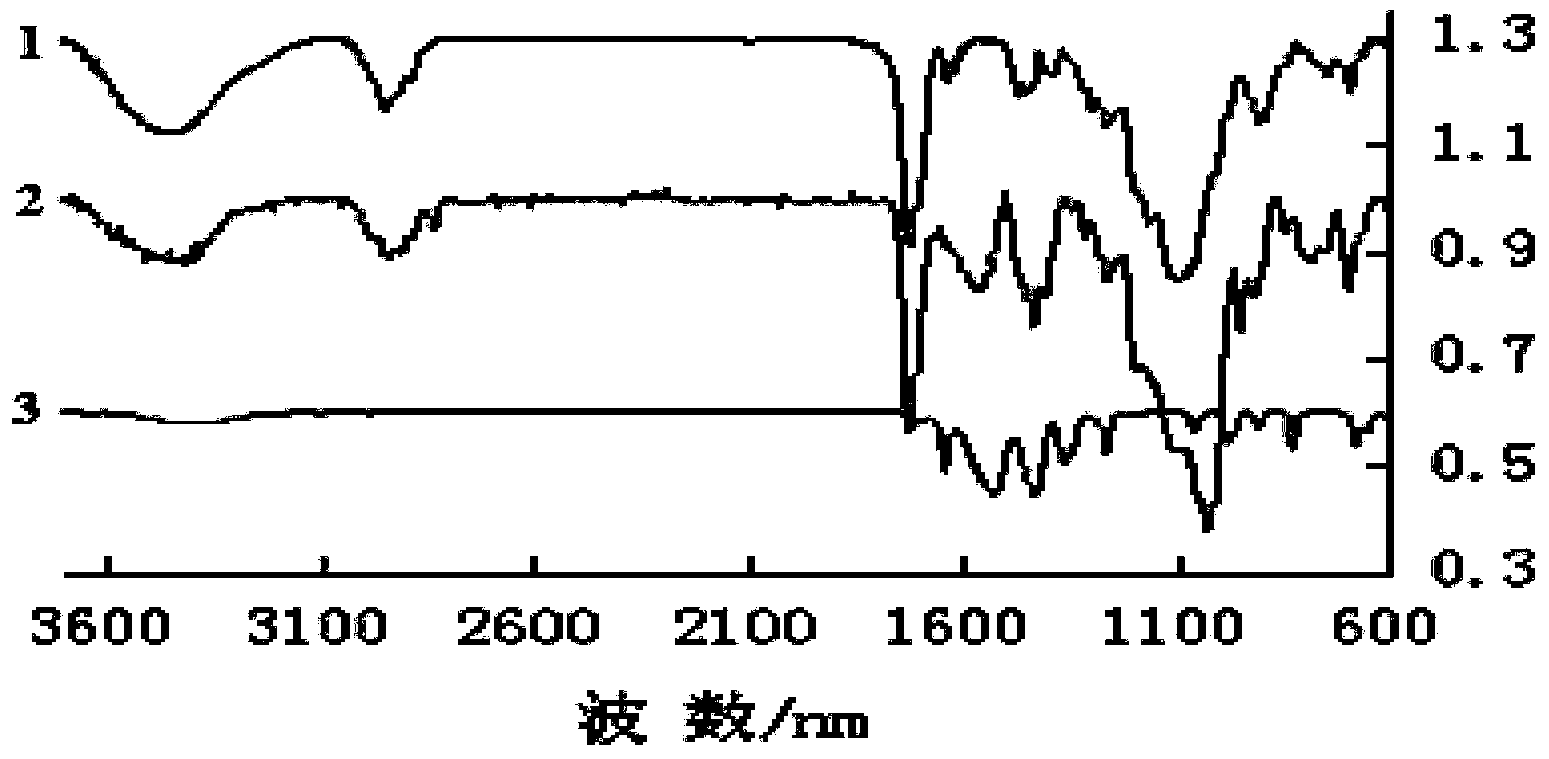

[0025] 1. Preparation of 3-(trimethoxysilyl) propyl acrylate hydrosol

[0026] Mix 1mL of 3-(trimethoxysilyl)propyl acrylate with 115uL of distilled water with a pH value of 2, adjust the pH value of the distilled water with hydrochloric acid, leave it to age at room temperature for 6 hours, and obtain 3-(trimethoxysilyl base) propyl acrylate hydrosol.

[0027] 2. Preparation of europium acrylate-organic silica sol

[0028] Dissolve 1.6 g of europium acrylate completely in 2 mL of dimethyl sulfoxide, then add 1.0 g of 3-(trimethoxysilyl)propyl acrylate hydrosol and 0.1 g of 2,4,6-trimethylbenzoyl-di Phenylphosphine oxide, uniform ultrasonic dispersion, to obtain europium acrylate-organic silicon sol.

[0029] 3. UV curing

[0030] The acrylate europium-organosilicon sol obtained in step 2 was irradiated with an ultraviolet surface light source with a wavelength of 365nm for 10 minutes, wherein the distance between the sample and the light source was 20cm to obtain a transpa...

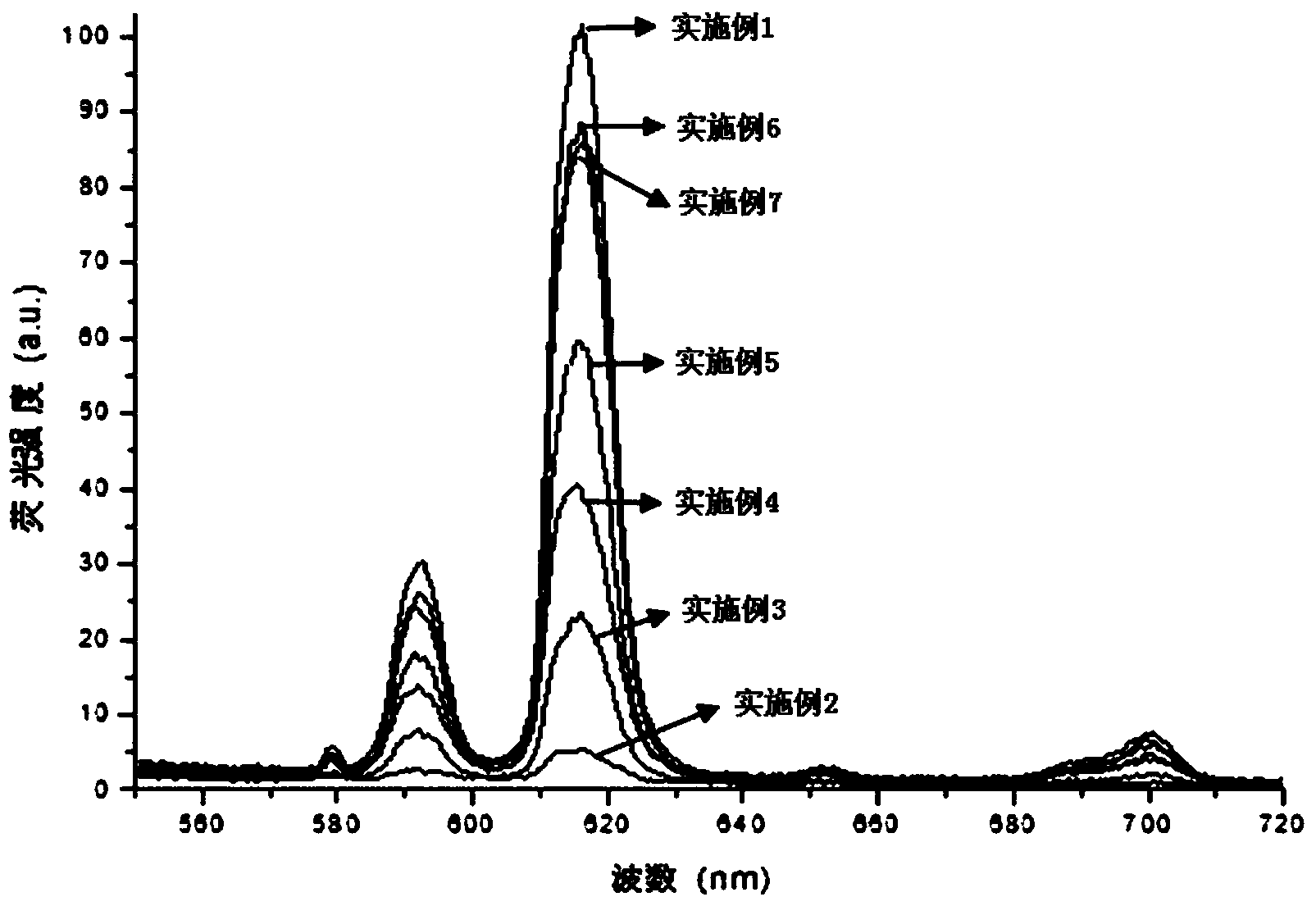

Embodiment 2

[0032] In step 2 of the preparation of europium acrylate-organic silica sol in this example, 0.05 g of europium acrylate was completely dissolved in 0.25 mL of dimethyl sulfoxide, and then 1.0 g of 3-(trimethoxysilyl) propyl acrylate hydrosol was added and 0.06g of 2,4,6-trimethylbenzoyl-diphenylphosphine oxide, and dispersed uniformly by ultrasonic to obtain europium acrylate-organic silicon sol. Other steps were the same as in Example 1 to obtain a uniform and transparent europium-bonded fluorescent gel glass.

Embodiment 3

[0034] In step 2 of the preparation of europium acrylate-organic silica sol in this example, 0.33 g of europium acrylate was completely dissolved in 0.4 mL of dimethyl sulfoxide, and then 1.0 g of 3-(trimethoxysilyl) propyl acrylate hydrosol was added and 0.06g of 2,4,6-trimethylbenzoyl-diphenylphosphine oxide, and dispersed uniformly by ultrasonic to obtain europium acrylate-organic silicon sol. Other steps were the same as in Example 1 to obtain a uniform and transparent europium-bonded fluorescent gel glass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com