Non-dismantling heat preservation wall module unit

A modular unit and thermal insulation wall technology, applied in thermal insulation, building thermal insulation materials, walls, etc., can solve the problems of easy existence of cold bridges in the wall, cumbersome construction steps, hidden dangers to residents' safety, etc., and achieve the effect of preventing smashing collapse and saving energy. Good, overall high-strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

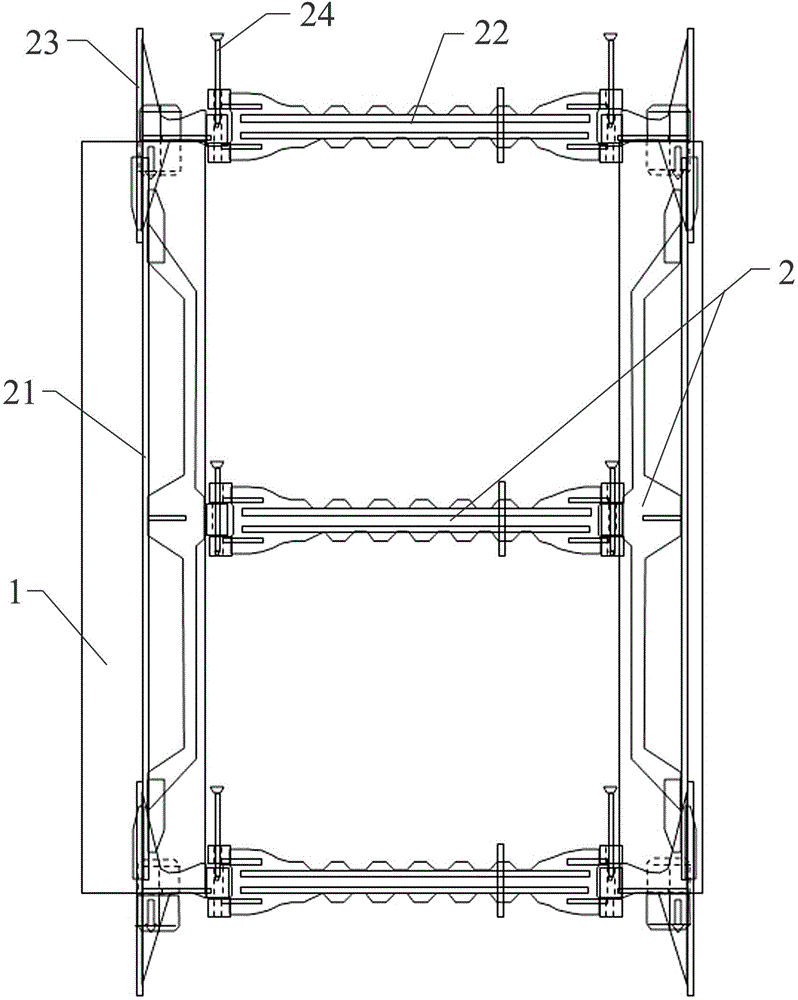

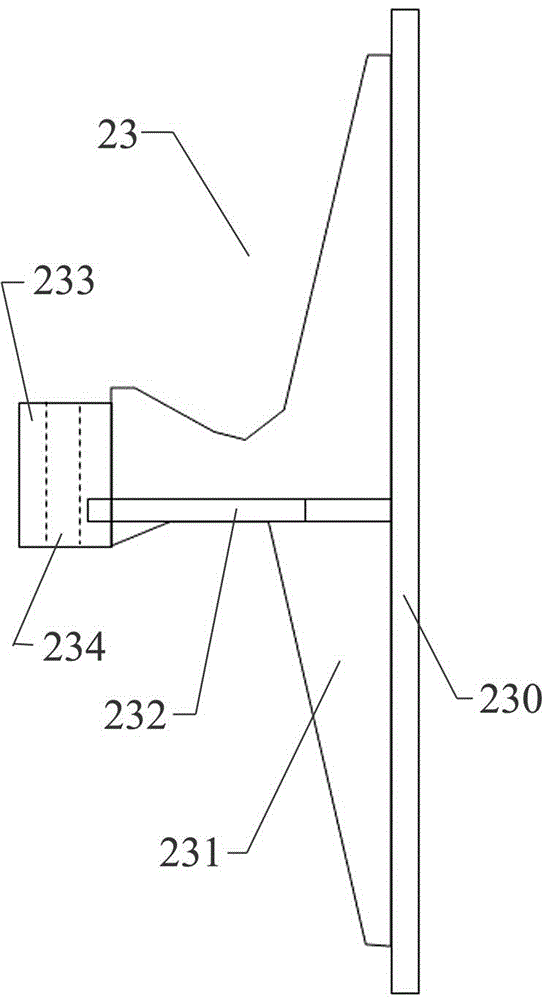

[0037] Example 1, such as figure 1 and figure 2 As shown, a modular unit of a dismantling-free thermal insulation wall includes a basic component and a supporting connecting component 2, the basic component is used to define the basic structure of the wall, and the supporting connecting component 2 is fixedly connected to the basic component for strengthening the wall and fixation.

[0038] Such as image 3 As shown, the basic component includes a pair of oppositely arranged insulation boards 1, the distance between the pair of insulation boards 1 is set according to the wall thickness requirements, and the cavity between the pair of insulation boards 1 is used for pouring concrete. The insulation board 1 adopts EPS benzene board, and the insulation board 1 includes the insulation board body 11, the insulation board body 11 is a rectangular plate, the upper surface of the insulation board body 11 is provided with bosses 12 and grooves 13 arranged at intervals, the insulatio...

Embodiment 2

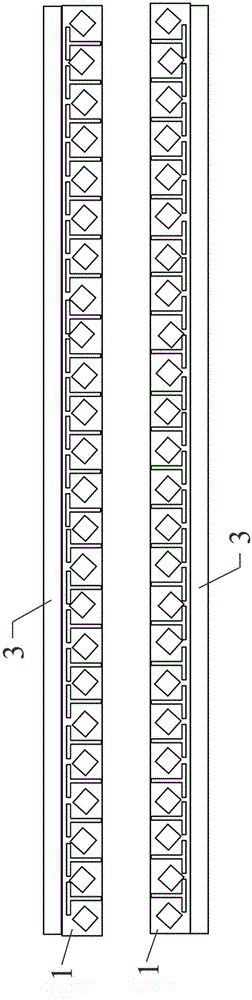

[0056] Example 2, such as Figure 11 As shown, a non-dismantling thermal insulation wall module unit includes a pair of thermal insulation boards 1 arranged oppositely. The outer side of the thermal insulation board 1 is provided with a fireproof board 3, and the fireproof board 3 is made of a class A fireproof material.

[0057] All the other structures are with embodiment 1.

Embodiment 3

[0058] Example 3, such as Figure 12 As shown, a kind of disassembly-free thermal insulation wall module unit includes a thermal insulation board 1, and the thermal insulation board 1 includes a thermal insulation board body 11. The outer surface of the thermal insulation board body 11 is provided with an outer side groove 4, and the outer side groove 4 is used for Accommodating the anti-flapping device of the heat preservation board, the outer surface groove 4 is arranged at one end close to the upper surface of the heat preservation board body 11 .

[0059] All the other structures are with embodiment 1.

[0060] The thickness of the thermal insulation board 1 in the above three embodiments can be adjusted according to the requirements of use. The thermal insulation board 1 arranged oppositely includes an inner formwork and an outer formwork, and the thickness of the outer formwork is greater than or equal to the thickness of the inner formwork.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com