Single-crystal high-temperature alloy thin-wall casting based on secondary orientation control and preparation method thereof

A technology for high-temperature alloys and thin-walled castings, applied in the field of high-temperature alloys, can solve problems affecting the mechanical properties of alloys, and achieve the effects of reducing manual errors, precise control, and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The invention provides a method for preparing a single crystal superalloy thin-walled casting based on secondary orientation control, comprising the following steps:

[0035] Cut out the seed crystal 1 with the required primary orientation and secondary orientation on the single crystal superalloy sample;

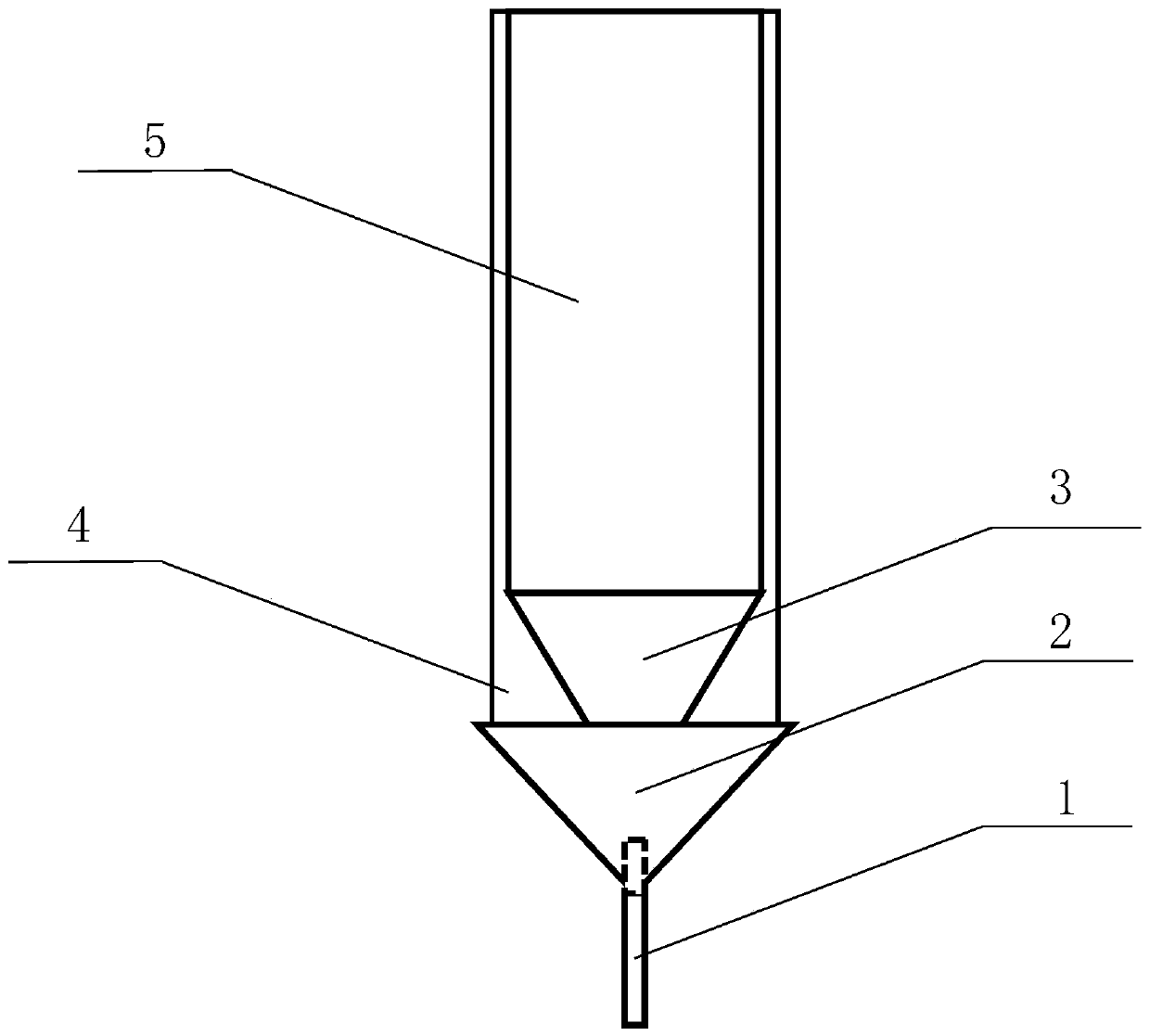

[0036] The seed crystal 1 is inserted into the triangular prism primary amplifier 2 to obtain a seed crystal amplifier combination; the material of the primary amplifier 2 is wax;

[0037] The wax paper 5 is attached to the surface of the ceramic sheet 4, and a wax pattern is formed on the surface of the ceramic sheet 4; the shape and size of the wax paper are the same as the target single crystal superalloy thin-walled casting; The top edges of 4 coincide;

[0038] Attach the secondary amplifier 3 to the lower end of the ceramic sheet 4 on the same side of the wax pattern to obtain a support wax pattern amplifier combination; the secondary amplifier 3 is an inverte...

Embodiment 1

[0067] Prepare a single crystal thin-walled casting with the axial direction and the side normal direction :

[0068]Step 1: Use the Laue X-ray diffraction method to calibrate the crystal orientation on the single crystal superalloy (Ni-6Al-3Ta-3Cr-3Co-6Mo) sample, and cut out the direction of the direction in the axial direction, and the normal direction of the side is A cuboid single crystal sample in the direction is used as a seed crystal, the bottom surface is 2.5mm×2.5mm, and the height is 30mm. The prepared seed crystals were successively polished by 60#, 360#, 600#, 1000#, 1500# and 2000# water sandpaper, and then used 20% H 2 o 2 +80% HCl (volume fraction) mixed solution was corroded for 10 minutes, and the seed crystal material with controlled secondary orientation was obtained after ultrasonic cleaning.

[0069] Step 2: Punch or cut the wax material into a triangular prism as the primary amplifier 2. The height of the triangular prism is 10 mm, the bottom is an...

Embodiment 2

[0074] Prepare a single crystal thin-walled casting with the axial direction and the side normal direction :

[0075] Step 1: Use the Laue X-ray diffraction method to calibrate the crystal orientation on the single crystal superalloy (Ni-6Al-3Ta-3Cr-3Co-6Mo) sample, and cut out the direction of the direction in the axial direction, and the normal direction of the side is A cuboid single crystal sample in the direction is used as a seed crystal, with a bottom surface of 3mm×3mm and a height of 24mm. The prepared seed crystals were successively polished by 60#, 360#, 600#, 1000#, 1500# and 2000# water sandpaper, and then used 20% H 2 o 2 +80% HCl (volume fraction) mixed solution was corroded for 10 minutes, and the seed crystal material with controlled secondary orientation was obtained after ultrasonic cleaning.

[0076] Step 2: Punch or cut the wax material into a triangular prism as the primary amplifier 2. The height of the triangular prism is 10 mm, the bottom is an is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com