Electric-eddy-type coupling-beam damper

An eddy current and damper technology, applied in the engineering field, can solve the problems of insufficient energy dissipation capacity of the structural system, poor overall seismic performance, poor seismic performance, etc., and achieve the effect of significant energy consumption, easy design, and high sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

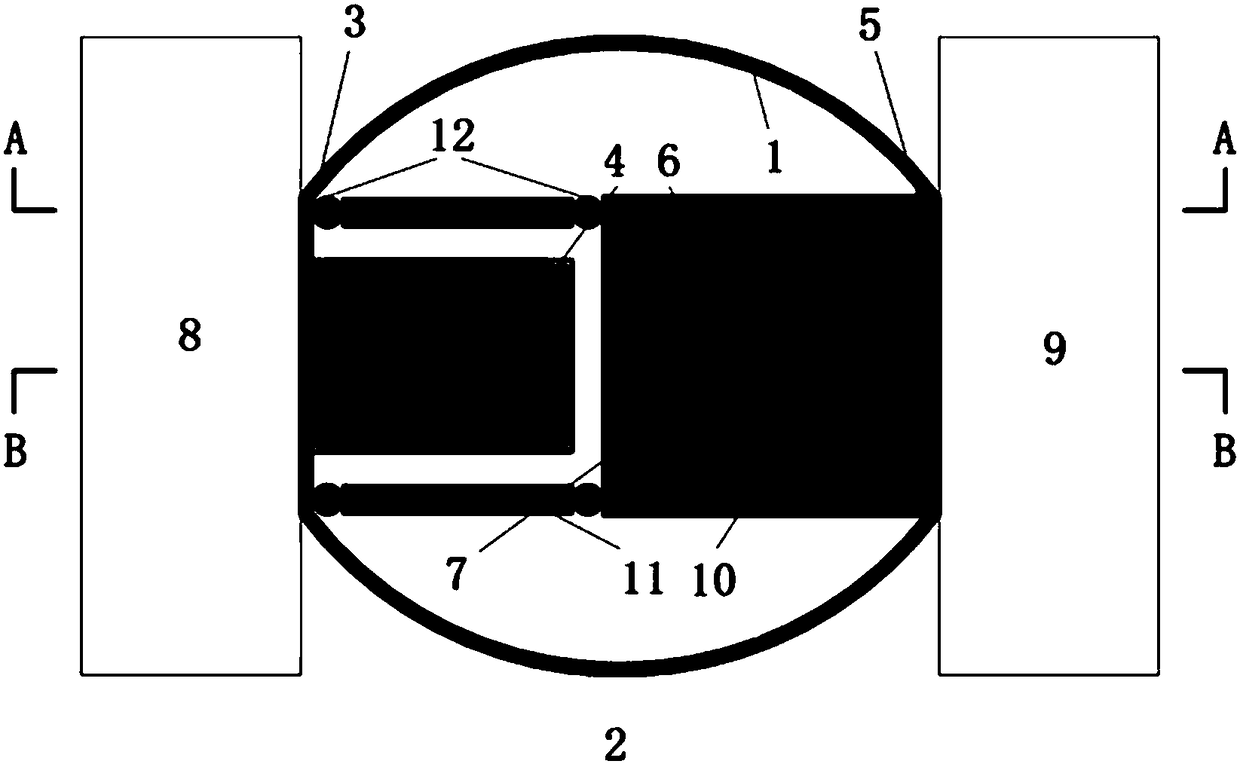

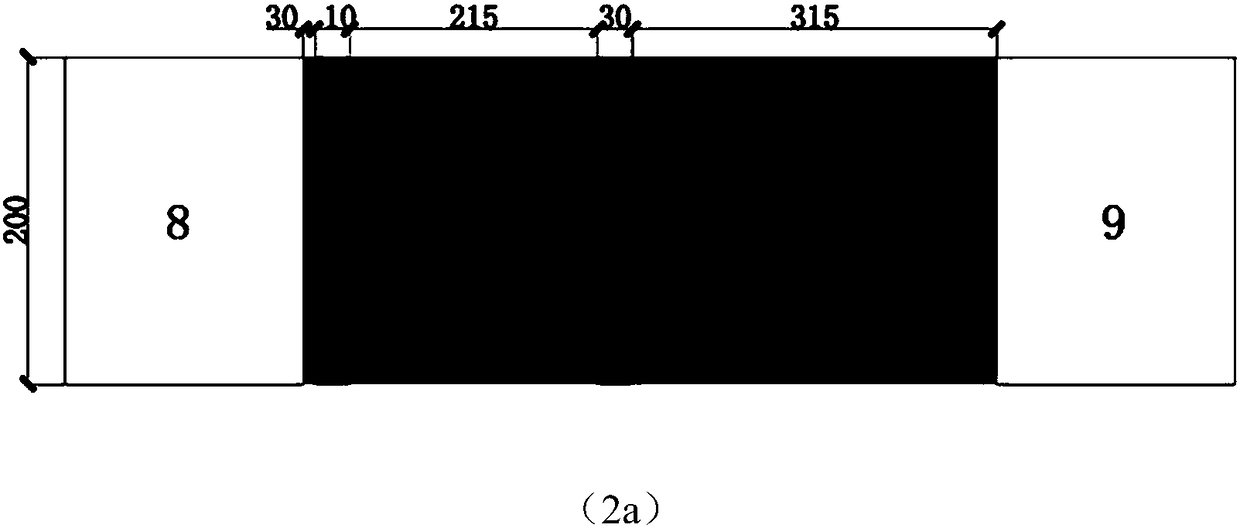

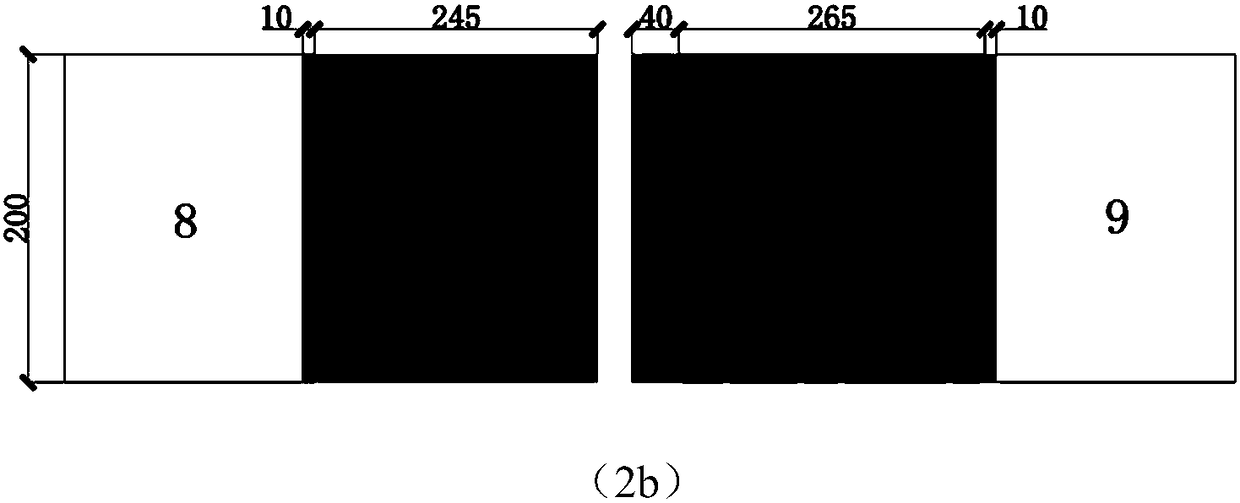

[0027] Among the current energy-dissipating and shock-absorbing components, the coupling beam damper is a kind of shock-absorbing control device suitable for the assembled shear wall structure: it is in an elastic state under the action of a small earthquake, and the damper provides a certain stiffness to the main structure to ensure The normal use requirements of the structure; under the action of a large earthquake, the damper first enters the state of energy consumption, produces greater damping, dissipates the energy input by the earthquake, and weakens the dynamic response of the structure, while the main structure does not appear obvious elastic-plastic, thus Ensure the safety of the structure under the action of strong earthquakes. The invention aims to propose an eddy current type coupling beam damper, which overcomes the bottleneck of the prefabricated shear wall shock absorption technology, and provides reference for the shock absorption design of the prefabricated sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com