Hollow silicon gel nano powder material and its preparation method

A technology of silica gel nano and bulk materials, applied in the direction of silicon oxide, silicon dioxide, etc., can solve the problems of the absence of a large-scale continuous hollow structure, encapsulation and release restrictions, unfriendly reagents, etc., and achieve nano-sphere particle size. and the shell wall thickness is easy to control, the structure is stable, and the effect of excellent safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1) Add 1.0mL of 30% sodium polyacrylate aqueous solution (the average molecular weight of sodium polyacrylate is 2.5KDa) to 26.2mL of deionized water under magnetic stirring conditions, 2.2mL of ammonia water and 0.6mL of molar concentration are 0.5mol / L calcium nitrate aqueous solution, the solution was stirred at room temperature for more than 2 minutes to obtain a clear mixed aqueous solution of sodium polyacrylate and calcium nitrate for subsequent use;

[0034] 2) Add 1.6mL tetraethyl orthosilicate to 70mL absolute ethanol under magnetic stirring condition, stir at room temperature for 2 minutes, set aside;

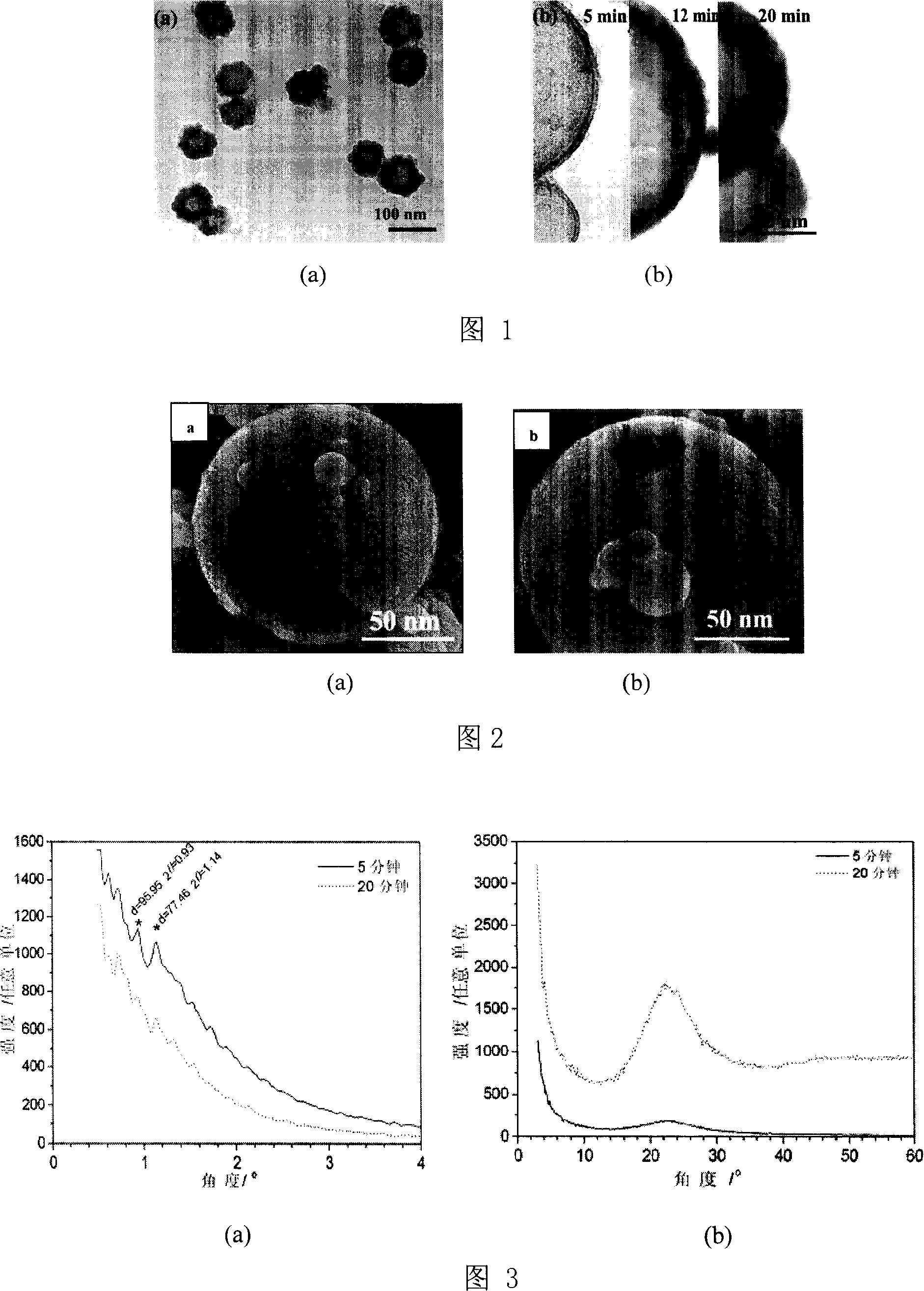

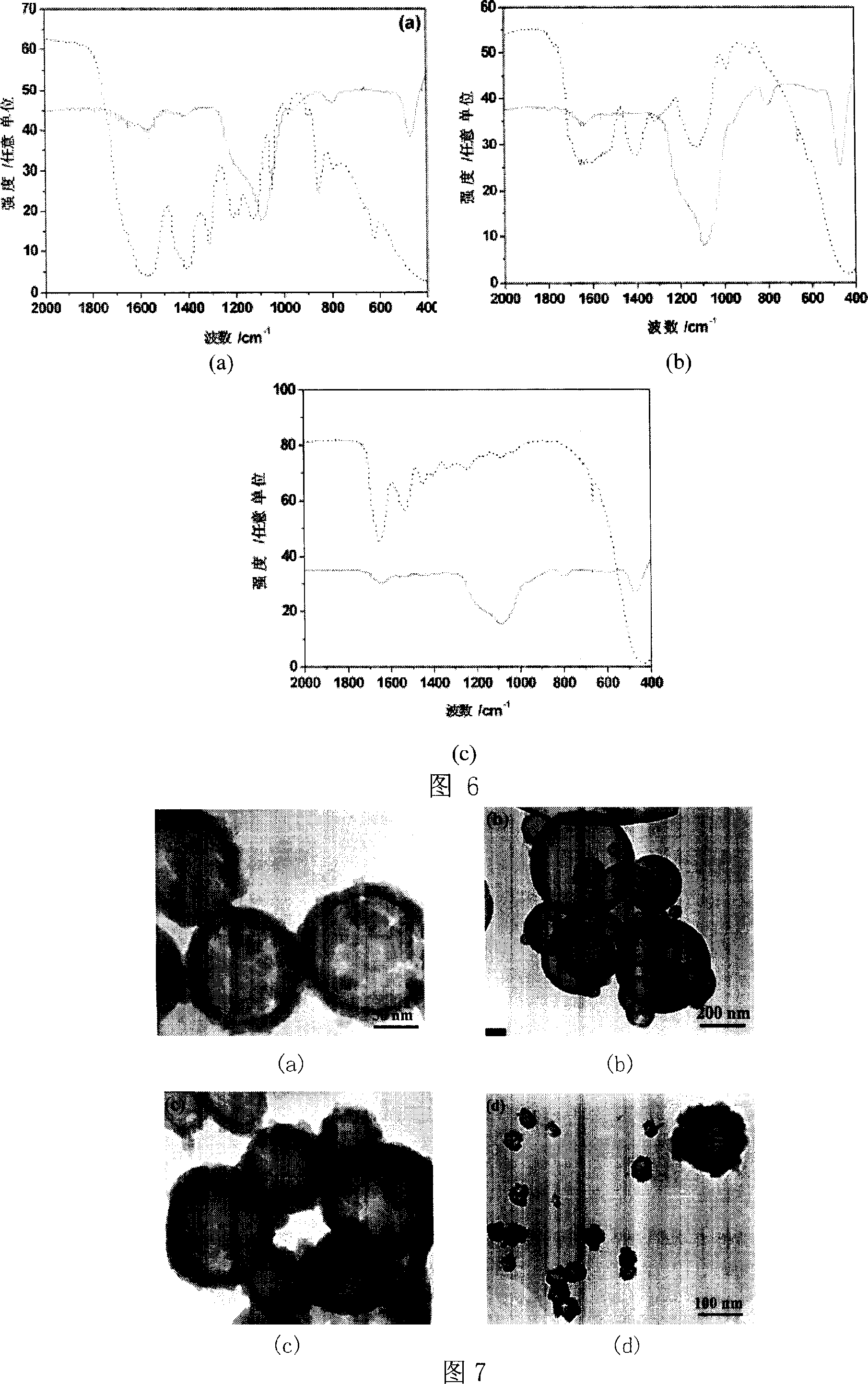

[0035] 3) Pour the mixed aqueous solution of clarified sodium polyacrylate and calcium nitrate prepared in step 1) into a clean three-necked flask, and place it in a water bath of an ultrasonic cleaner (40KHz, 80W), turn on the ultrasonicator, and add Stir mechanically (240rpm), then add the ethyl tetrasilicate ethanol solution prepared in step 2) into the abo...

Embodiment 2

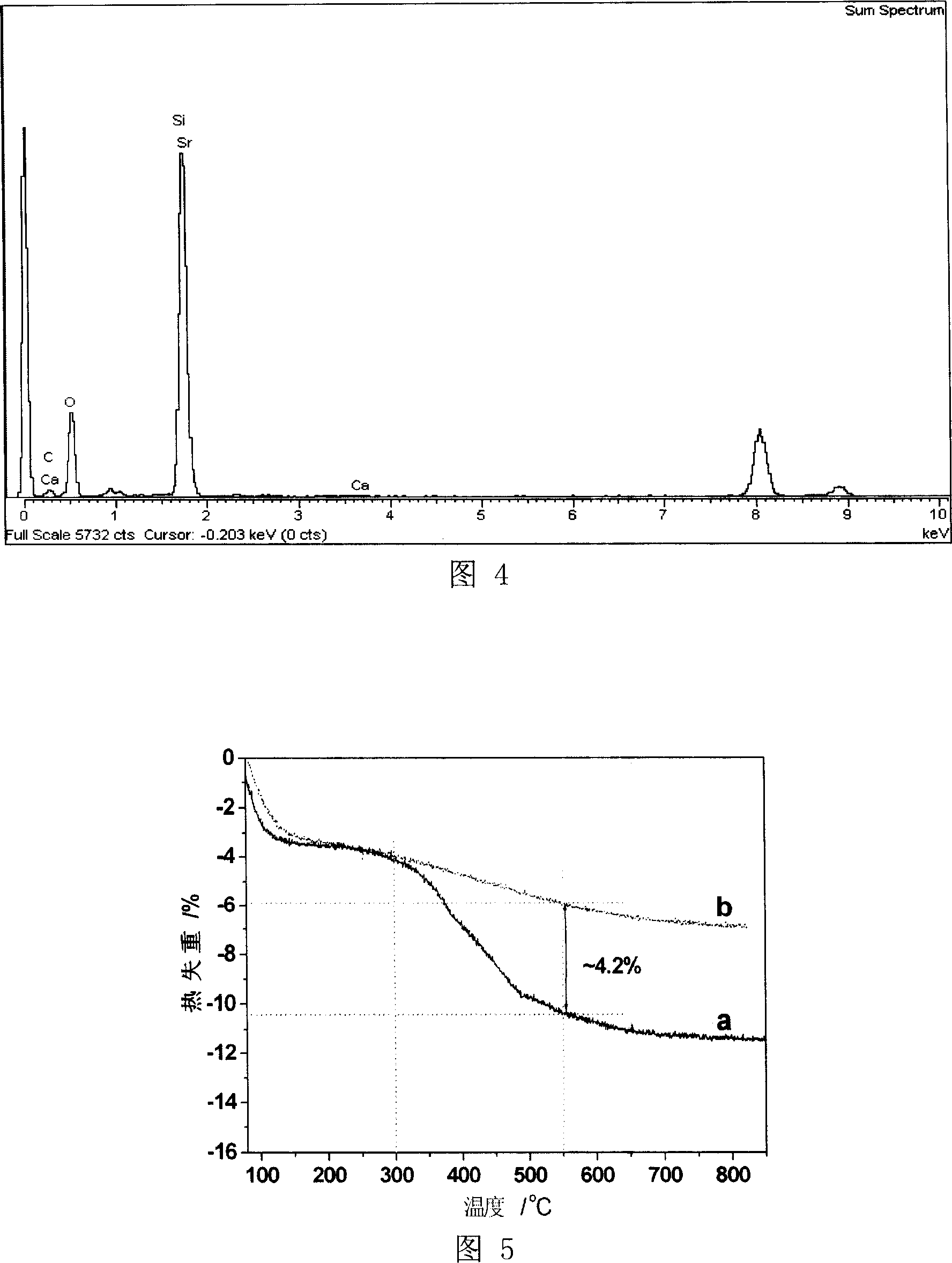

[0037] 1) Add 1.5mL of 2% sodium polyacrylate aqueous solution (the average molecular weight of sodium polyacrylate is 1000KDa) to 15.5mL of deionized water successively under magnetic stirring conditions, 2.5mL of ammonia water and 0.5mL with a molar concentration of 0.5 mol / L strontium nitrate aqueous solution, the solution was stirred at room temperature for more than 2 minutes to obtain a clear mixed aqueous solution of sodium polyacrylate and strontium nitrate for subsequent use;

[0038] 2) Add 2.0 mL of tetraethyl orthosilicate to 78 mL of absolute ethanol under magnetic stirring conditions, stir at room temperature for 2 minutes, and set aside.

[0039] 3) Pour the mixed aqueous solution of clarified sodium polyacrylate and strontium nitrate prepared in step 1) into a clean three-necked flask, and place it in the water bath of the ultrasonic cleaner equipment, turn on the ultrasonic cleaner, and add mechanical stirring (300rpm) into the flask , and then adding the etha...

Embodiment 3

[0041] Same as Example 1, the difference is that 1.2mL of sodium polyaspartate with an average molecular weight of 5KDa is used to replace 1.0mL of sodium polyacrylate with an average molecular weight of 2.5KDa, the product is hollow silica gel nanospheres (Figure 7c), and the particles The molecular content of sodium polyaspartate on the outer surface is extremely low (see Figure 6b).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com