Workpiece combined clamp for abrasive wheel cutting machine

A grinding wheel cutting machine and combined fixture technology, which is applied in the direction of manufacturing tools, grinding machine parts, metal processing equipment, etc. The effect of damage to the grinding wheel and the safety of the cutting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

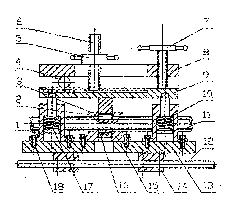

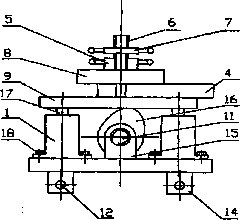

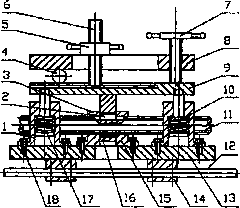

[0013] The present invention will be further described below in conjunction with the accompanying drawings and the specific embodiments given in the accompanying drawings.

[0014] See figure 1 and figure 2 , a workpiece combination fixture for a grinding wheel cutting machine is composed of a clamping mechanism and an elastic movement mechanism. The clamping mechanism includes a pressure plate 8 and a bottom plate 9 for clamping the workpiece, and the workpiece 4 is clamped between the pressure plate 8 and the bottom plate 9 . Between the upper side of the pressure plate 8 and the bottom plate 9, there are compression screw rods 6 and compression nuts 5 that cooperate with the light holes of the pressure plate 8. Adjust the compression nuts 5 to compress or loosen the clamping of the workpiece. hold or tightness. The upper panel of the base plate 9 is provided with a "T" groove, and the lower end of the compression screw 6 is slidably matched with the "T" groove, so as to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com