Laser cutting device for flexible display

A laser cutting and flexible display technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as difficult alignment, decreased cutting accuracy, and short tool life, and achieves small cutting resistance and small cutting gaps. Narrow and stable cutting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

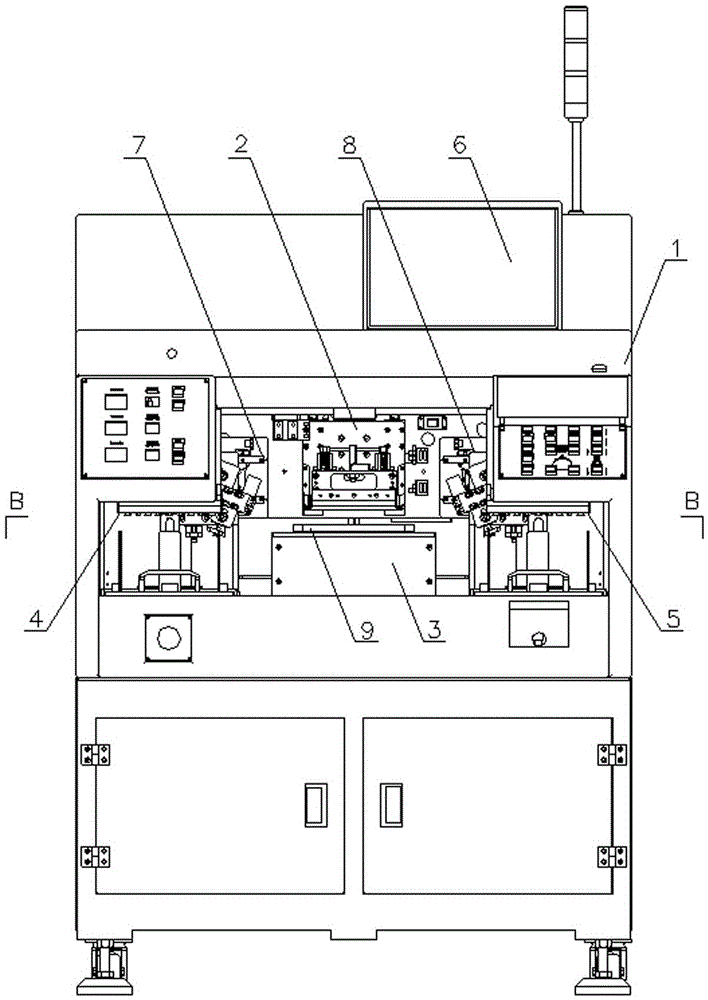

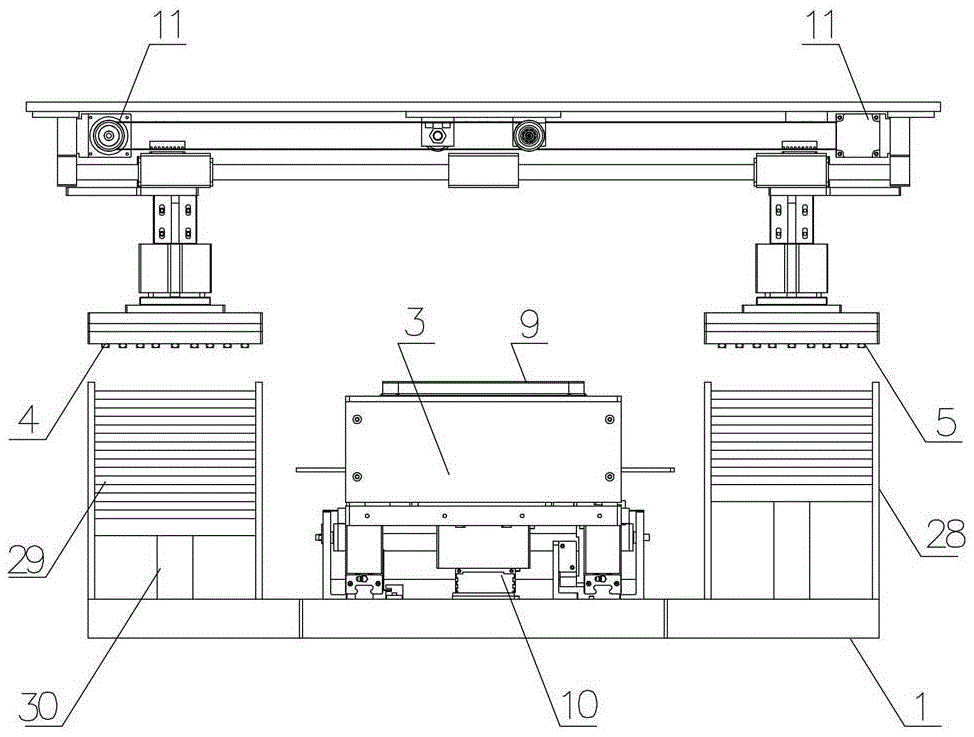

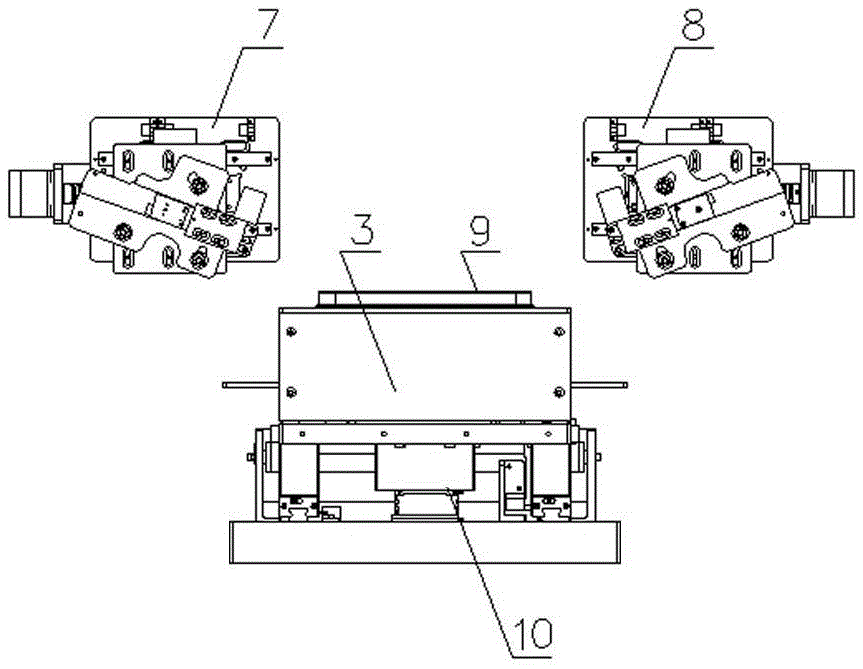

[0027] figure 1 Schematic diagram of laser cutting equipment for flexible displays. Including body structure, carrier, detection and positioning mechanism, cutting mechanism, control system, and operation panel, there is a vacuum channel inside the carrier, and a feeding and receiving mechanism is set above the left and right sides of the carrier, see figure 2 , The feeding and receiving mechanism is equipped with a vacuum suction cup and a feeding and receiving transmission motor. Below the vacuum suction cup, a silo for accessing products is set. In the body structure at the bottom of the silo, there is an electric ejector rod that moves up and down. See Figure 4 , the lower part of the stage is connected to the workbench. At the connection between the stage and the workbench, there is a servo rotation mechanism that allows the stage to rotate 180 degrees relative to the workbench. A direct drive mechanism that allows the workbench to move forward and backward in a straig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com