Preparation method of flying saucer welding slotted piece

A technology of slotted pieces and flying saucers, which is applied in the field of preparation of flying saucer-type welded slotted pieces, can solve the problems of not being able to adapt to the slotting, the efficiency needs to be improved, and it is difficult to meet the road surface, so as to improve the cutting efficiency, improve the cutting performance, and reduce the cost of the substrate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

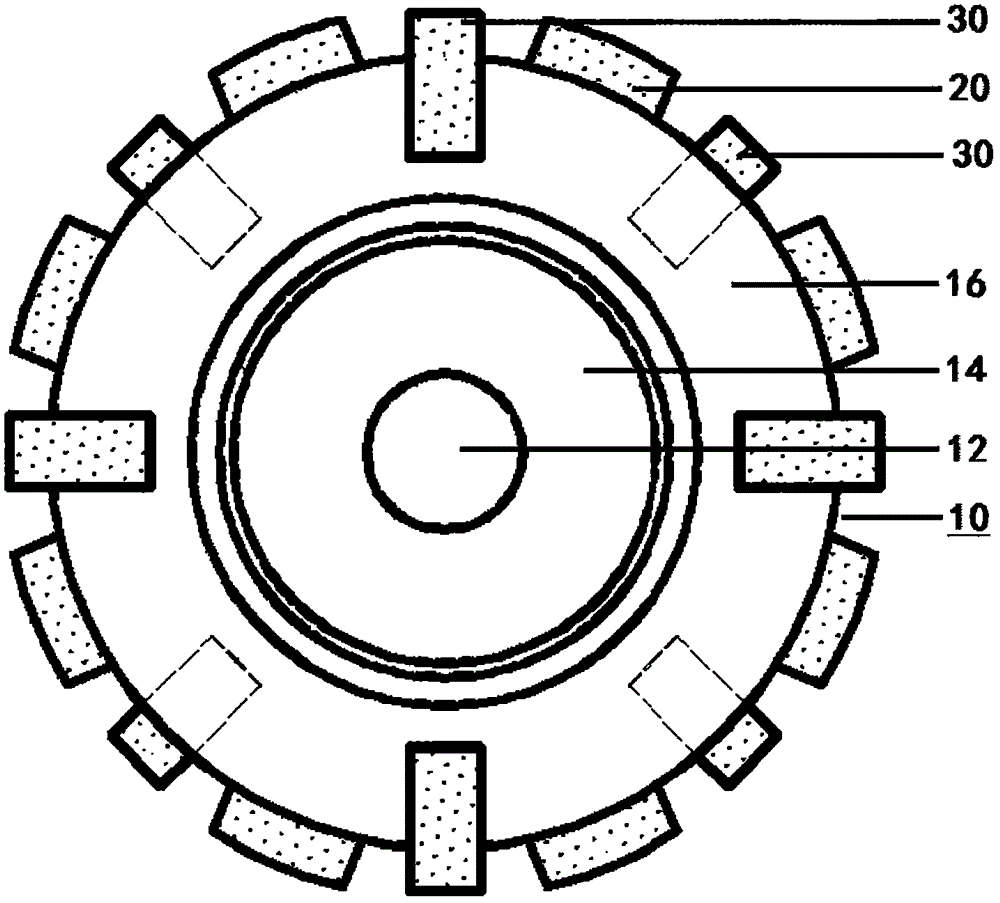

[0026] The flying saucer type welded slotted piece of the present embodiment comprises a heat-resistant steel matrix with a diameter of 108 mm. The heat-resistant steel matrix is composed of an inner area and a peripheral annular area. The center of the inner area is provided with a shaft hole, and the inner area is also formed with The ring-shaped thickened platform has a peripheral ring-shaped area with a gradually thinning thickness from the center to the outside. The peripheral annular area 12 is provided with a diamond main tooth cutter head 20 and a diamond mouthguard cutter head 30 with a height of 9 mm. The diamond mouthpiece bits 30 are evenly distributed on the front and back surfaces of the peripheral annular area at intervals of 45°, and the length of the exposed base end is 8 mm. The end wall of the peripheral annular area between the adjacent diamond mouthguard cutter heads 30 is welded with diamond main tooth cutter heads, and the angle between adjacent diamon...

Embodiment 2

[0028]The flying saucer type welded slotted piece of the present embodiment comprises a heat-resistant steel matrix with a diameter of 108 mm. The heat-resistant steel matrix is composed of an inner area and a peripheral annular area. The center of the inner area is provided with a shaft hole, and the inner area is also formed with The ring-shaped thickened platform has a peripheral ring-shaped area with a gradually thinning thickness from the center to the outside. The peripheral annular area 12 is provided with a diamond main tooth cutter head and a diamond mouthguard cutter head with a height of 9 mm. The diamond mouthpiece bits 30 are evenly distributed on the front and back surfaces of the peripheral annular area at intervals of 45°, and the length of the exposed base end is 8 mm. The end wall of the peripheral annular area between the adjacent diamond mouthguard cutter heads 30 is welded with diamond main tooth cutter heads, and the angle between adjacent diamond main ...

Embodiment 3

[0030] The flying saucer type welded slotted piece of the present embodiment comprises a heat-resistant steel matrix with a diameter of 108 mm. The heat-resistant steel matrix is composed of an inner area and a peripheral annular area. The center of the inner area is provided with a shaft hole, and the inner area is also formed with The ring-shaped thickened platform has a peripheral ring-shaped area with a gradually thinning thickness from the center to the outside. The peripheral annular area 12 is provided with a diamond main tooth cutter head and a diamond mouthguard cutter head with a height of 9 mm. The diamond mouthpiece bits 30 are evenly distributed on the front and back surfaces of the peripheral annular area at intervals of 45°, and the length of the exposed base end is 8 mm. The end wall of the peripheral annular area between the adjacent diamond mouthguard cutter heads 30 is welded with diamond main tooth cutter heads, and the angle between adjacent diamond main...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com