Door/window frame plastic steel profile extrusion production line

A technology for door and window frames and production lines, which is applied in the field of plastic-steel door frame profiles, can solve problems such as poor section smoothness and a large number of chips, and achieve the effects of extending length, long contact time, and good drying quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

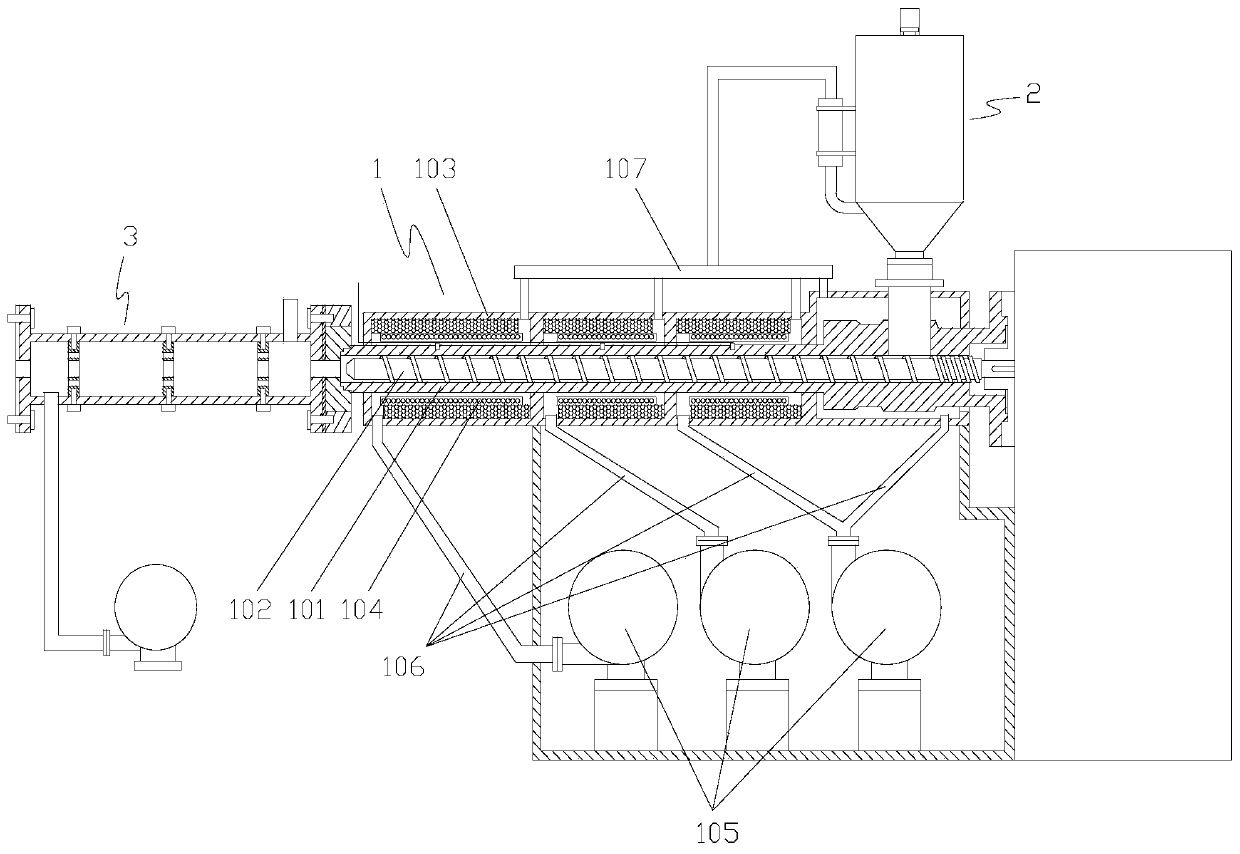

[0047] As shown in the figure, the door and window frame plastic steel profile extrusion production line in this embodiment includes an extruder 1, a hopper 2 connected to the feed port of the extruder, a water cooling device 3 connected to the head of the extruder, and a The downstream cutting device 4, and the discharge device 5 arranged downstream of the cutting device.

[0048] The extruder comprises a barrel 101, a screw 102 arranged in the barrel, a casing 103 arranged outside the barrel, an electromagnetic heater 104 arranged in the casing, and an air cooler for cooling the barrel. 105, the air outlet of the cooling fan is connected to the casing through the first air pipe 106, the first air pipe is used to send the cooling air into the annular cavity between the electromagnetic heater and the barrel, and the casing is also A second air duct 107...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com