Chip-free cutting apparatus used for plastic section bar

A technology of plastic profiles and cutting devices, which is applied in metal processing and other directions, can solve problems such as increased production costs, hidden dangers of production and maintenance, and easy chipping of cutters, so as to improve safety performance, prevent cutters from chipping, and buffer cutting resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

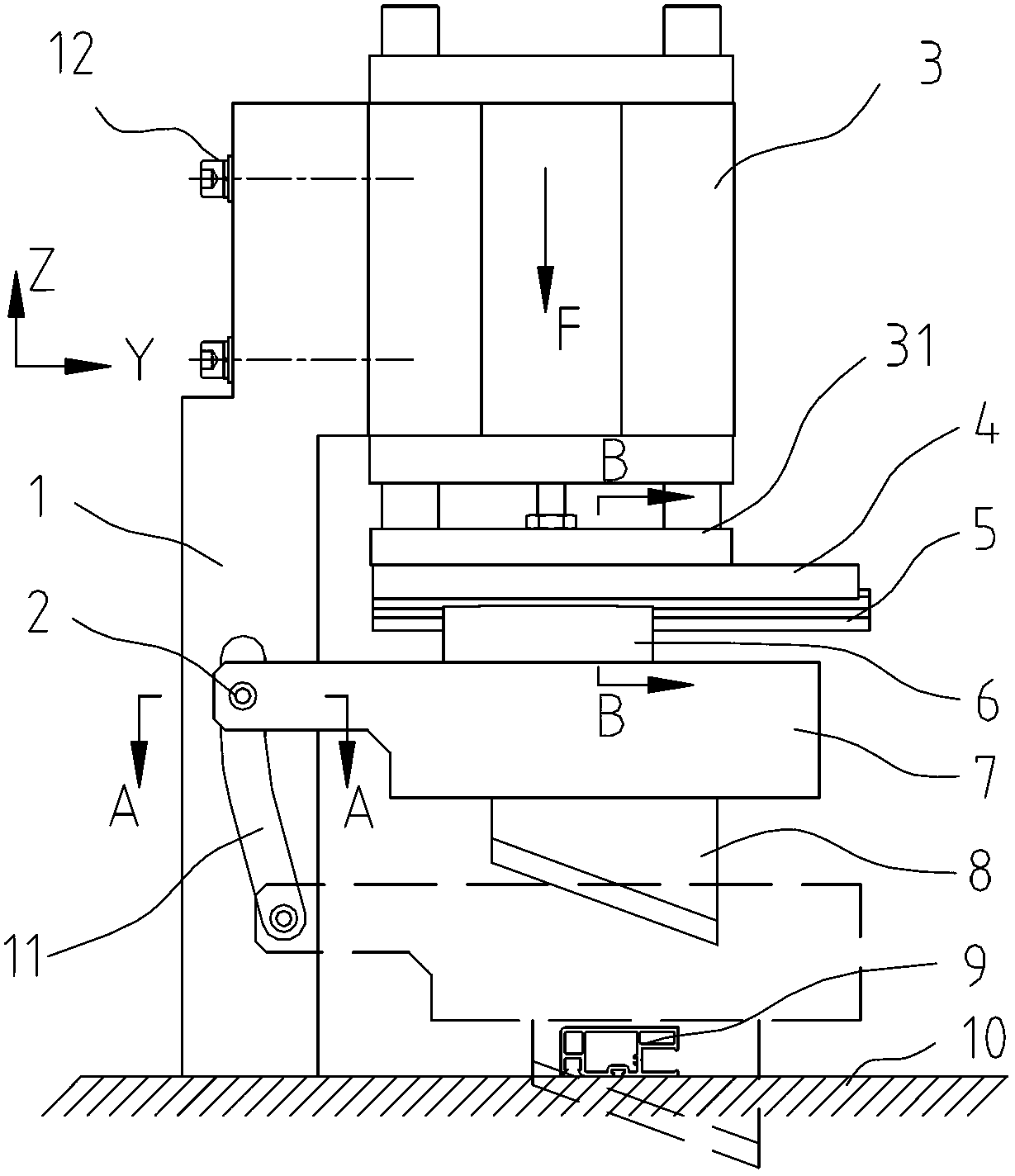

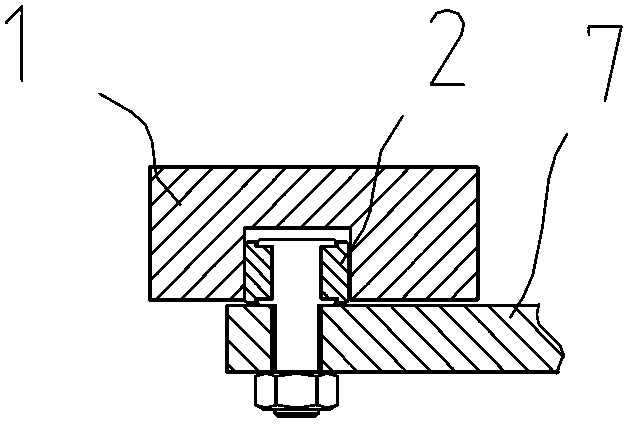

[0012] Such as figure 1 As shown, the support 1 is fixed on one side of the workbench 10, the driving cylinder 3 is fixed on the upper end of the support 1 by bolts 12, and the side of the support 1 is provided with a guide groove 11 inclined or curved from top to bottom to the cutting knife 8 side. One end of the frame 1 is fixed with a ball bearing follower 2 cooperating with the guide groove 11 on the bracket 1, see figure 2 , Cutter 8 is fixed on knife rest 7 lower ends.

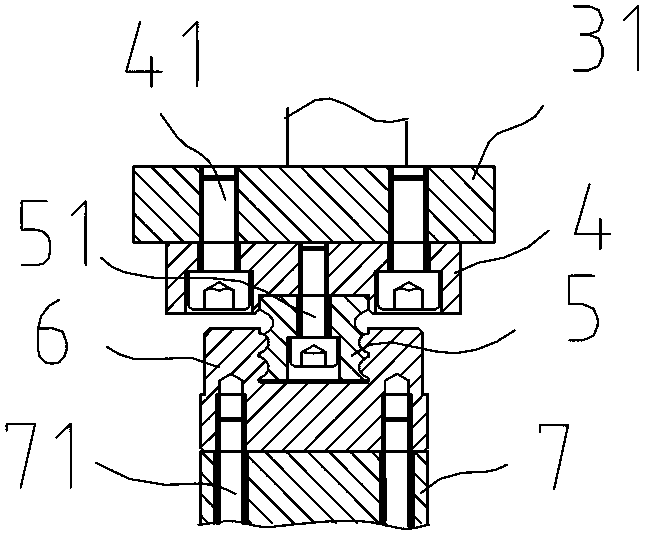

[0013] The knife rest 7 is connected with the cylinder head 31 of the driving cylinder 3 through a horizontal sliding device, and its structure is as follows: image 3 As shown, the guide rail frame 4 is fixed on the lower end of the cylinder head 31 of the drive cylinder by bolts 41, the linear guide rail 5 is fixed on the lower end of the guide rail frame 4 by bolts 51 along the horizontal direction of the plane where the cutting edge is located, and the slide block 6 is fixed by bolts 71 7. On the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com