Fiberglass mold

A glass fiber reinforced plastic mold and glass fiber reinforced plastic technology, applied in the field of parts manufacturing, can solve the problems of complex manufacturing process, waste of manpower, lack of any elasticity, etc., to save the repair process, improve product quality, and prevent corners from cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

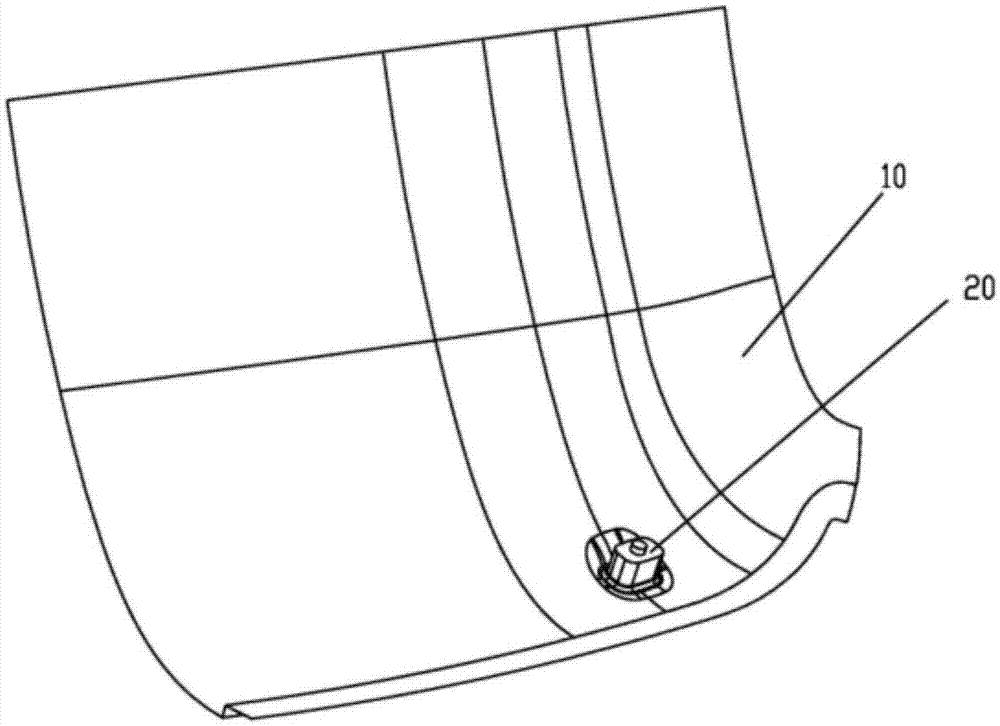

[0007] like figure 1 , a glass fiber reinforced plastic mold, including a main mold 10 and a secondary mold 20, the secondary mold 20 is fixed on the main mold 10 and the molding surface of the secondary mold 20 protrudes from the molding surface of the main mold 10, and the main mold 10 Adopt detachable connection with secondary mold 20. The forming surface in the present invention refers to the surface of the FRP mold used to process the product. The main mold 10 is used to shape the shape of the product, and the secondary mold 20 is used to shape the light holes, assembly holes, structural installation holes, etc. on the product. The secondary mold 20 protrudes on the molding surface of the main mold 10, the shape of the secondary mold 20 matches the shape and size of the hole to be processed, and the secondary mold 20 is generally a block structure. Since the auxiliary mold 20 and the main mold 10 are split structures, the main mold 10 and the auxiliary mold 20 can be pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com