Glass cutting method

A glass cutting and glass technology, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of product yield decline and glass chipping, and achieve the effect of preventing chipping and improving product yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

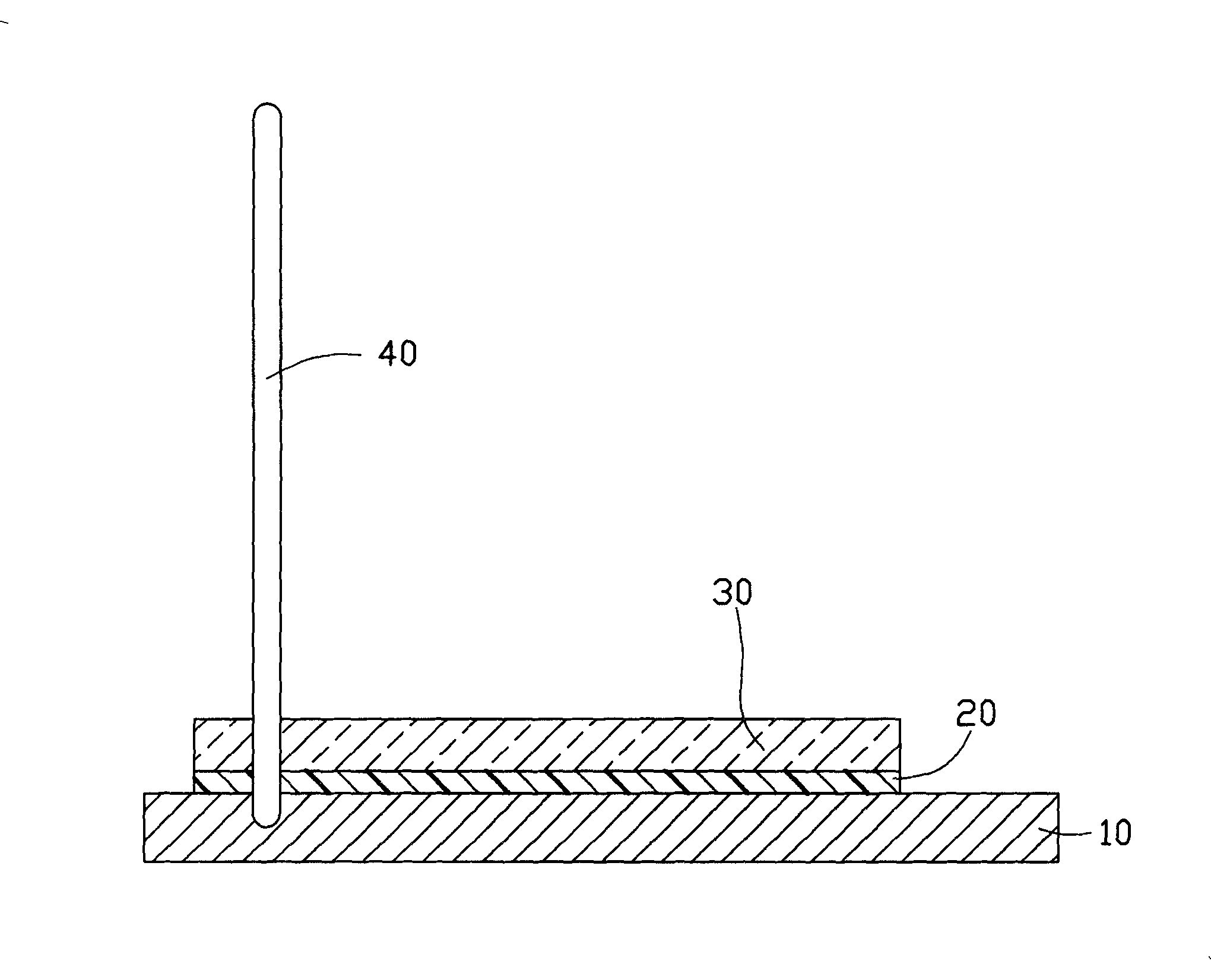

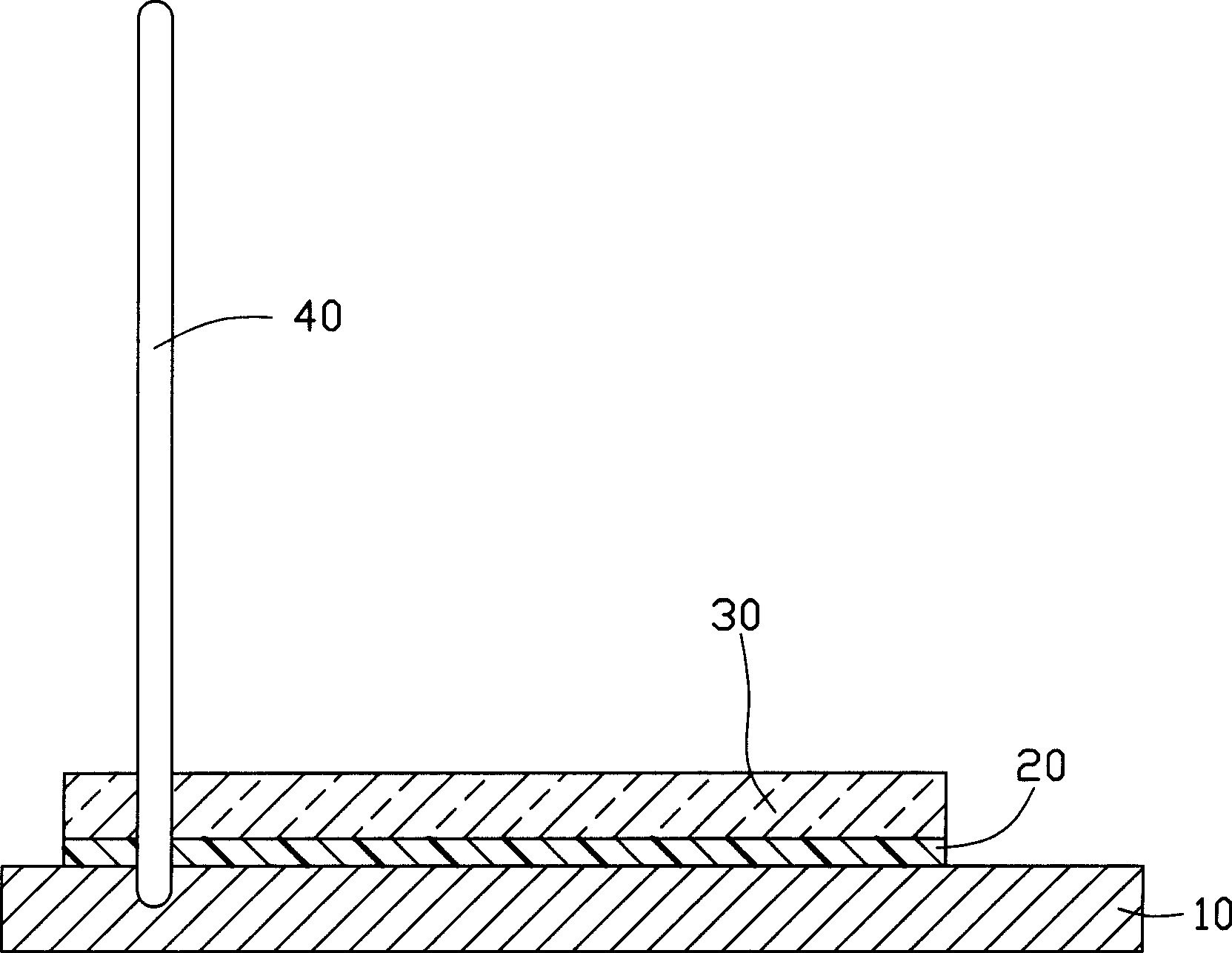

[0007] see figure 1 A preferred embodiment of the glass cutting method of the present invention includes the following steps: first, a base 10 is provided, and the base 10 is a glass base whose material is relatively hard. Apply an appropriate amount of water-soluble UV glue 20 on the base 10, then place a glass plate 30 to be cut on the water-soluble UV glue 20, and then use an ultraviolet (UV) light source curing machine (not shown) to cure The water-soluble UV glue. The water-soluble UV glue 20 has a weak viscosity before curing, but has a strong viscosity after curing, so as to firmly bond the glass plate 30 to the base 10 . After a cutting machine 40 cuts the glass plate 30 according to the predetermined size, an appropriate amount of water is provided to dissolve the cured water-soluble UV glue 20, and the finished glass product can be taken out.

[0008] It can be understood that the base 10 can also be made of other relatively hard materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com