Rapid self-making tool for coffee capsule and pressing method thereof

A coffee capsule, fast technology, applied in the directions of external support, transportation packaging, packaging, etc., can solve the problems of wasting the environment, prone to collapse, increase costs, etc., and achieve the effects of improving sealing effect, low production cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

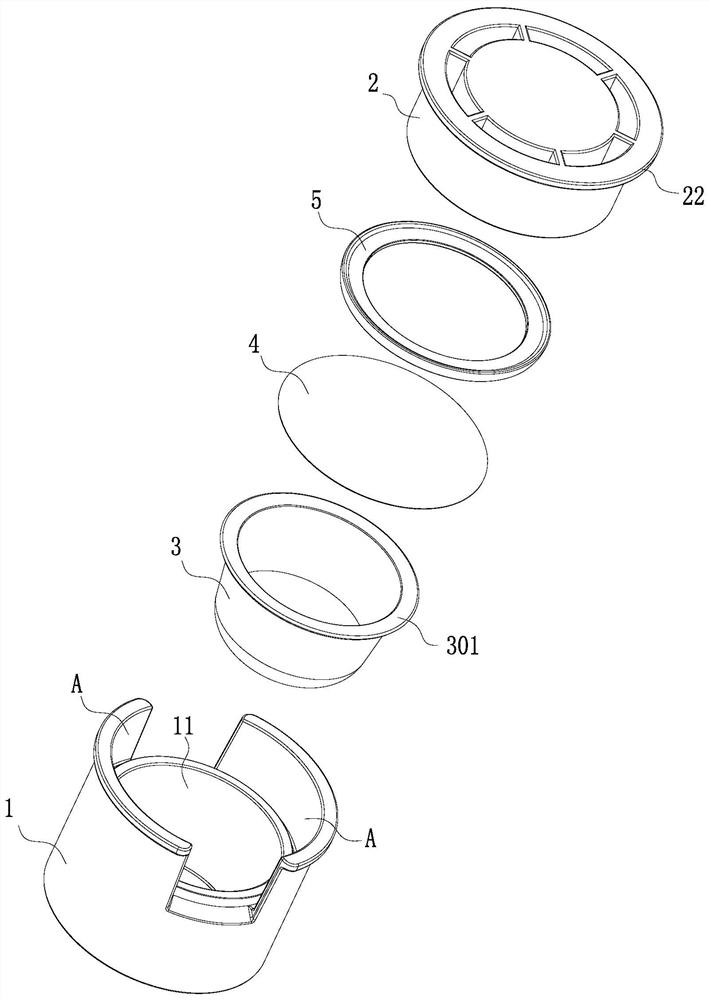

Embodiment approach 1

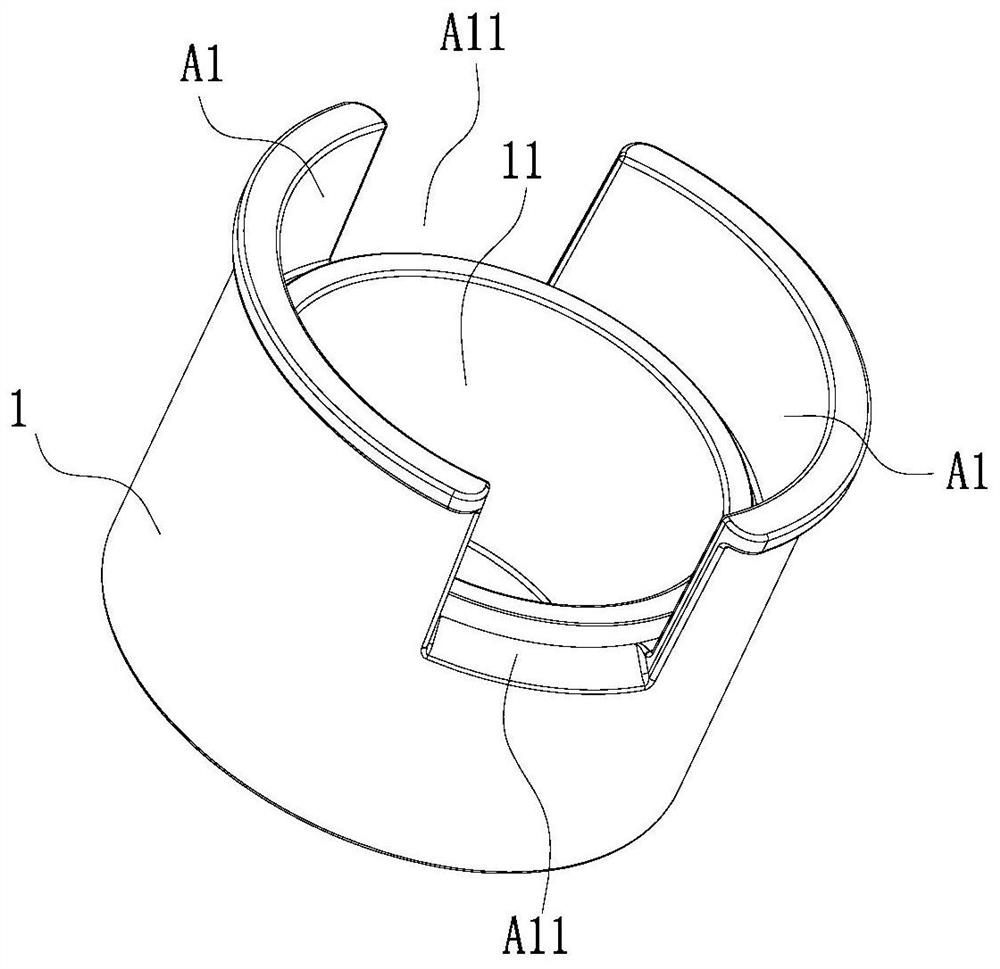

[0050] Implementation mode one: if figure 2 As shown, the guide member A includes two symmetrically arranged guide plates A1, the guide channels connected with the mold cavity 11 are formed between the guide plates A1, and the guide channels are suitable for vertically guiding the mold base 1 or the die 2; in this In the embodiment, both the mold base 1 and the die 2 adopt a circular structure, so the guide plate A1 is in an arc-shaped structure, and is arranged on the side edge of the die base 1, and the die base 2 is formed by the two guide plates A1. The vertical position can be maintained, and pressure can be evenly applied to the opening of the capsule shell 3 .

[0051] Two gaps A11 communicating with the guide channel are formed between the two guide plates A1. Before pressing, consumers can hold the capsule shell 3 with two fingers until the capsule shell 3 is put into the bottom of the mold cavity 11. After pressing, The pressed coffee capsules can also be removed f...

Embodiment approach 2

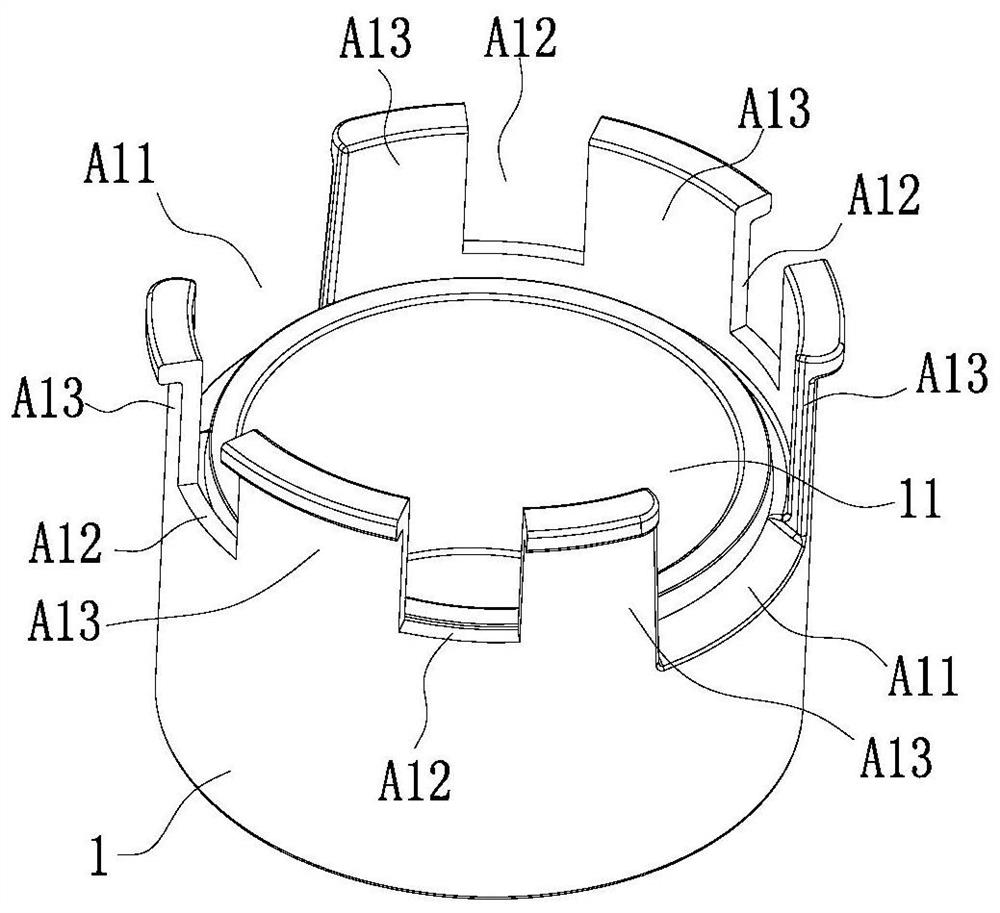

[0052] Embodiment 2: Embodiment 2 evolves on the basis of Embodiment 1, such as image 3 As shown, the guide plate A1 is provided with a plurality of through grooves A12, the through grooves A12 divide the guide plate A1 into a plurality of guide side plates A13, the through grooves A12 can increase the number of notches A11, making the coffee capsules easier to take out.

Embodiment approach 3

[0053] Implementation mode three: if Figure 4 As shown, the guide member A is a sleeve A2, which forms a guide channel communicating with the mold cavity 11. The guide channel is suitable for vertically guiding the mold base 1 or the die 2 up and down, and the shape of the sleeve A2 can be a closed loop ring shape, or arc shape with a single notch A11.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com