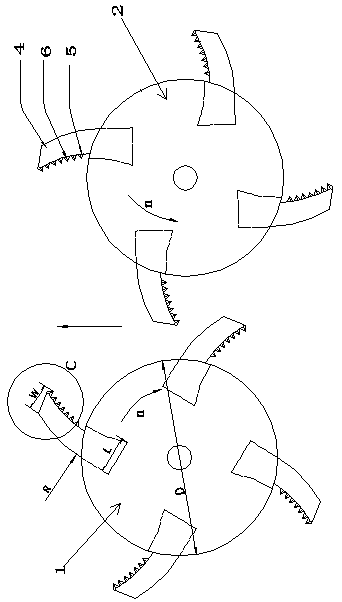

Bionic disc tool for cutting crop stalks

A disc cutter and cutting blade technology, which is applied in the field of agricultural machinery, can solve the problems of blade breakage and failure, high power consumption of disc cutters, short service life of cutters, etc., so as to reduce cutting resistance, improve work efficiency, and reduce work effort. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

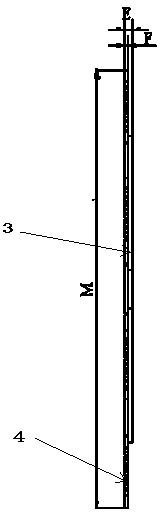

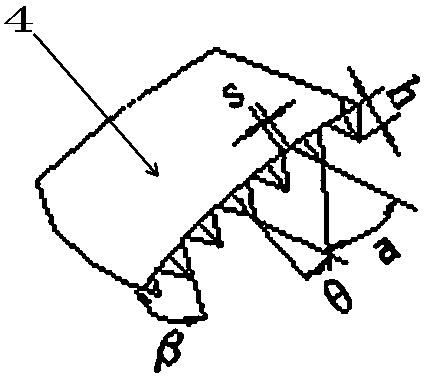

[0017] Example 1: The thickness of the rotating disk 3 is F=4mm, the thickness of the cutting blade 4 is E=2mm, the overall diameter of the cutter head is M=240mm, the diameter of the rotating disk 3 is D=160mm, and the number of 4 cutting blades is Z=4, and the cutting blade is 4 Top width w=21mm, cutting blade 4 mounting end width L=30mm, cutting blade 4 radius R=95mm, tooth height h=4mm, tooth surface apex angle a=60°, tooth face inclination angle β=60°, tooth edge angle θ=30°, tooth gap s=2mm.

example 2

[0018] Example 2: The thickness of the rotating disk 3 is F=4mm, the thickness of the cutting blade 4 is E=2mm, the overall diameter of the cutter head is M=240mm, the diameter of the rotating disk 3 is D=160mm, the number of cutting blades 4 is Z=4, the cutting blade 4 Top width w=24mm, cutting blade 4 mounting end width L=30mm, cutting blade 4 radius R=96mm, tooth height h=4mm, tooth surface apex angle a=40°, tooth rake angle β=120°, tooth edge Angle θ=20°, tooth gap s=2.5mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com