Slurry for slicing silicon ingot and method for slicing silicon ingot using same

A technology of slurry and silicon ingots, applied in chemical instruments and methods, fine working devices, stone processing equipment, etc., can solve problems such as wire rope breakage and loss of safety factor, and achieve the effect of reducing cutting resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] 8 parts by mass of sodium hydroxide were dissolved in 100 parts by mass of water to make an alkaline aqueous solution, and the aqueous solution was mixed with 100 parts by mass of triethanolamine and 100 parts by mass of polyethylene glycol. To this mixed solution, 100 parts by mass of SiC abrasive grains (manufactured by Fujimi Inc., GC#1000, average particle diameter about 10 μm) were added and stirred to prepare a slurry for silicon ingot cutting. At this time, the mass ratio of triethanolamine to the water content in the liquid component of the slurry is 100÷100=1.0. In addition, the obtained slurry had a pH of 13.3 at 25°C, and an initial viscosity of 50 mPa·s at a shear rate of 57.6 / s at 90°C.

[0067] Using the obtained slurry for silicon ingot cutting, a polycrystalline silicon ingot sample (3 mm×3 mm×thickness 1 mm) was ground under the grinding conditions shown below. Each time the slurry is collected at the specified time (0, 2, 4, and 7 hours), the viscosity at ...

Embodiment 2

[0089] Using the same slurry for silicon ingot cutting as in Example 1, a polycrystalline silicon ingot sample (3 mm×3 mm×thickness 1 mm) was ground under the grinding conditions shown below. The polishing amount was obtained from the mass change of the sample before and after polishing, and the polishing time was divided by the polishing time to obtain the polishing speed. The results are shown in Table 3.

[0090] Grinding conditions

[0091] Grinding disc: 200mm in diameter (made by Buhler, buffer pad for polishing, super pad for 8-inch wafers)

[0092] Sample position: 65mm from the center of the disc

[0093] Rotation speed of grinding table: 200rpm

[0094] Grinding time: 5 minutes

[0095] Slurry supply: 65cc / min

[0096] Slurry supply position: 65mm from the center of the disk, behind the sample after 30° rotation

[0097] Slurry temperature: 80℃

[0098] Sample pressure: 10N

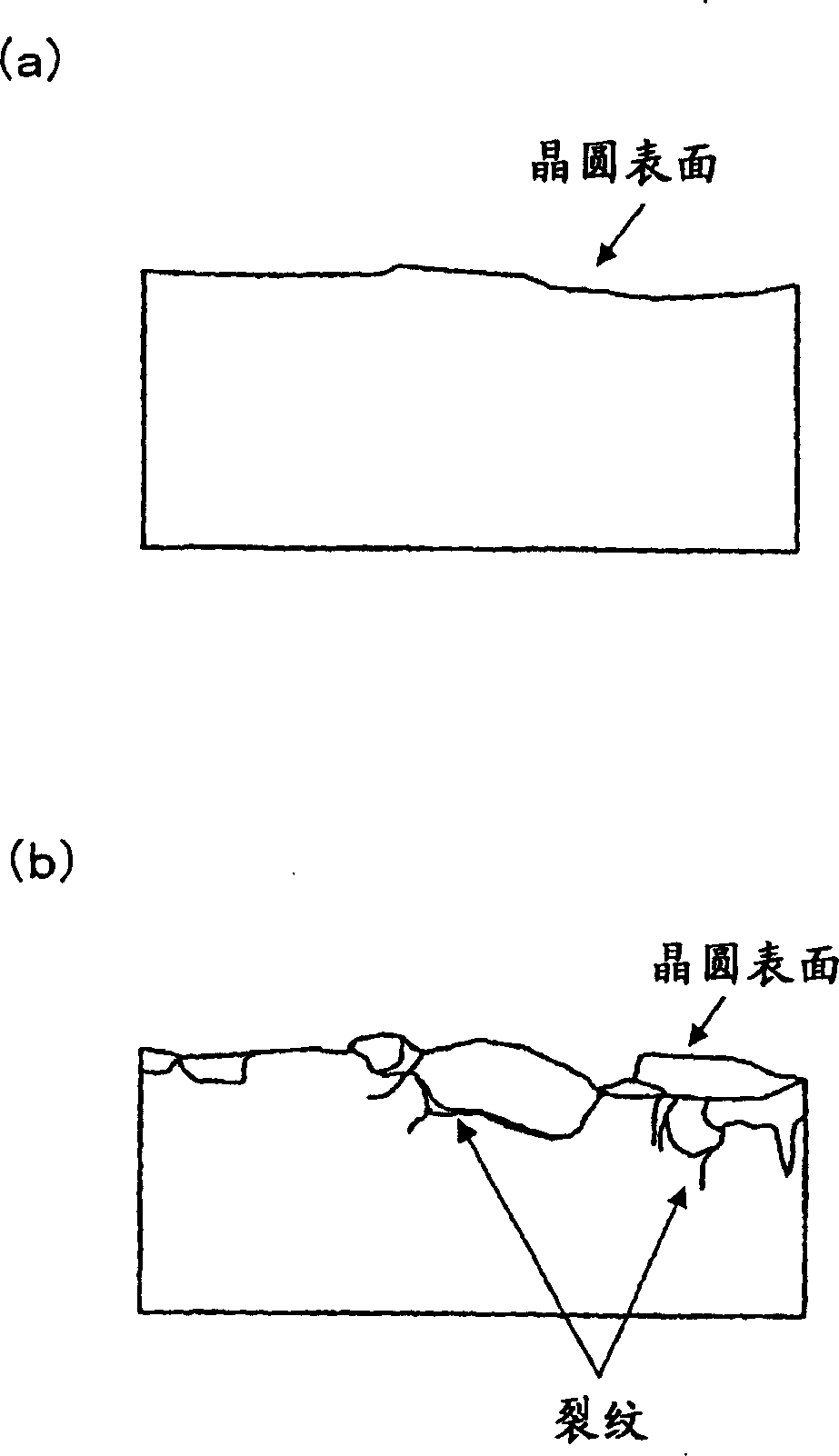

[0099] Next, the obtained wafer was washed with water, and after drying, the polished surface of...

Embodiment 3

[0114] A slurry for silicon ingot cutting was prepared. The slurry contained 4.9% by mass of sodium hydroxide relative to the total mass of the liquid component of the slurry, and contained triethanolamine at a mass ratio of 0.5 relative to the water in the liquid component of the slurry. The overall quality of the product contains 33% by mass of abrasive grains, and the difference in cutting resistance caused by the difference in slurry temperature has been examined. In addition, the pH of the obtained slurry at 25°C was 13.8.

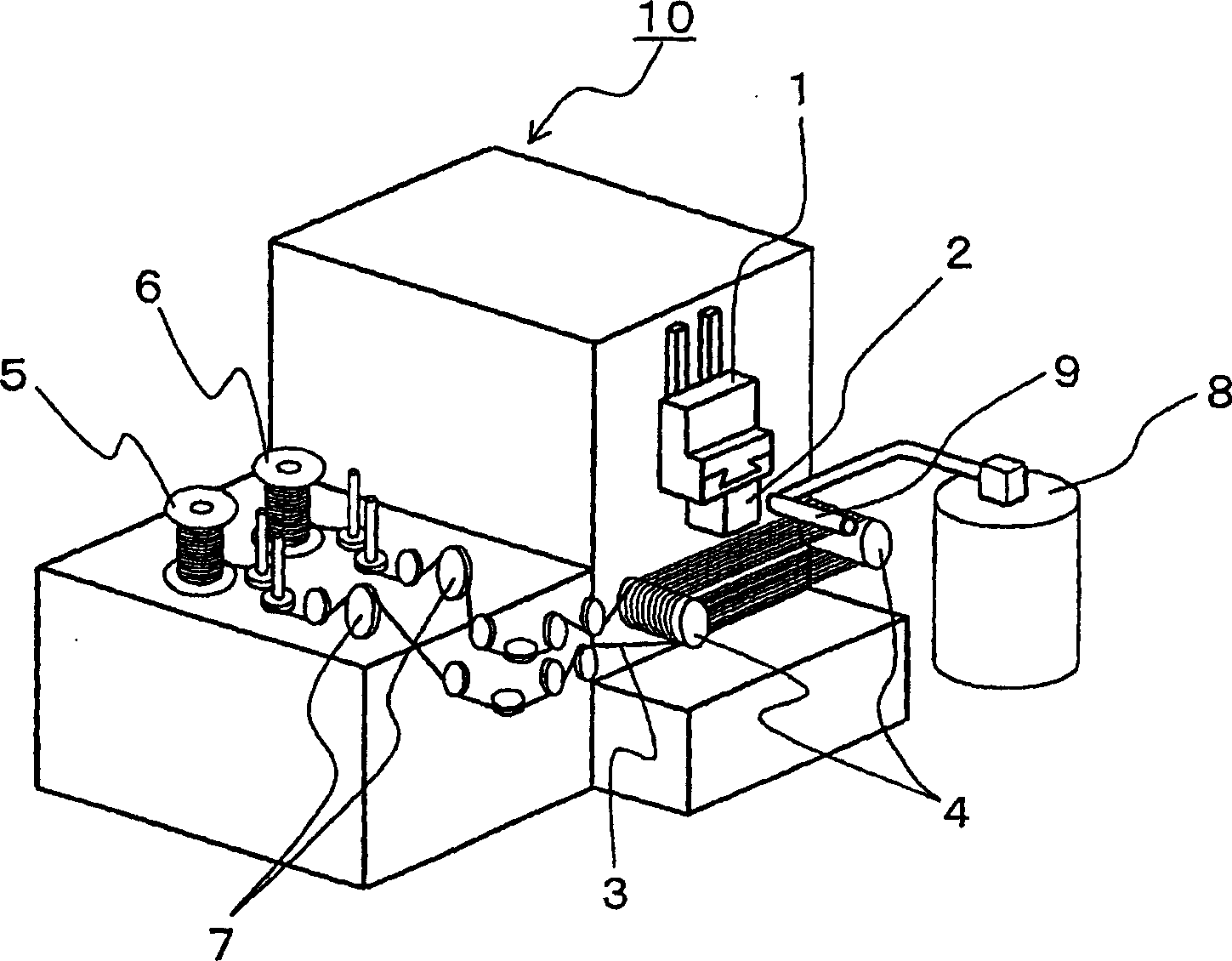

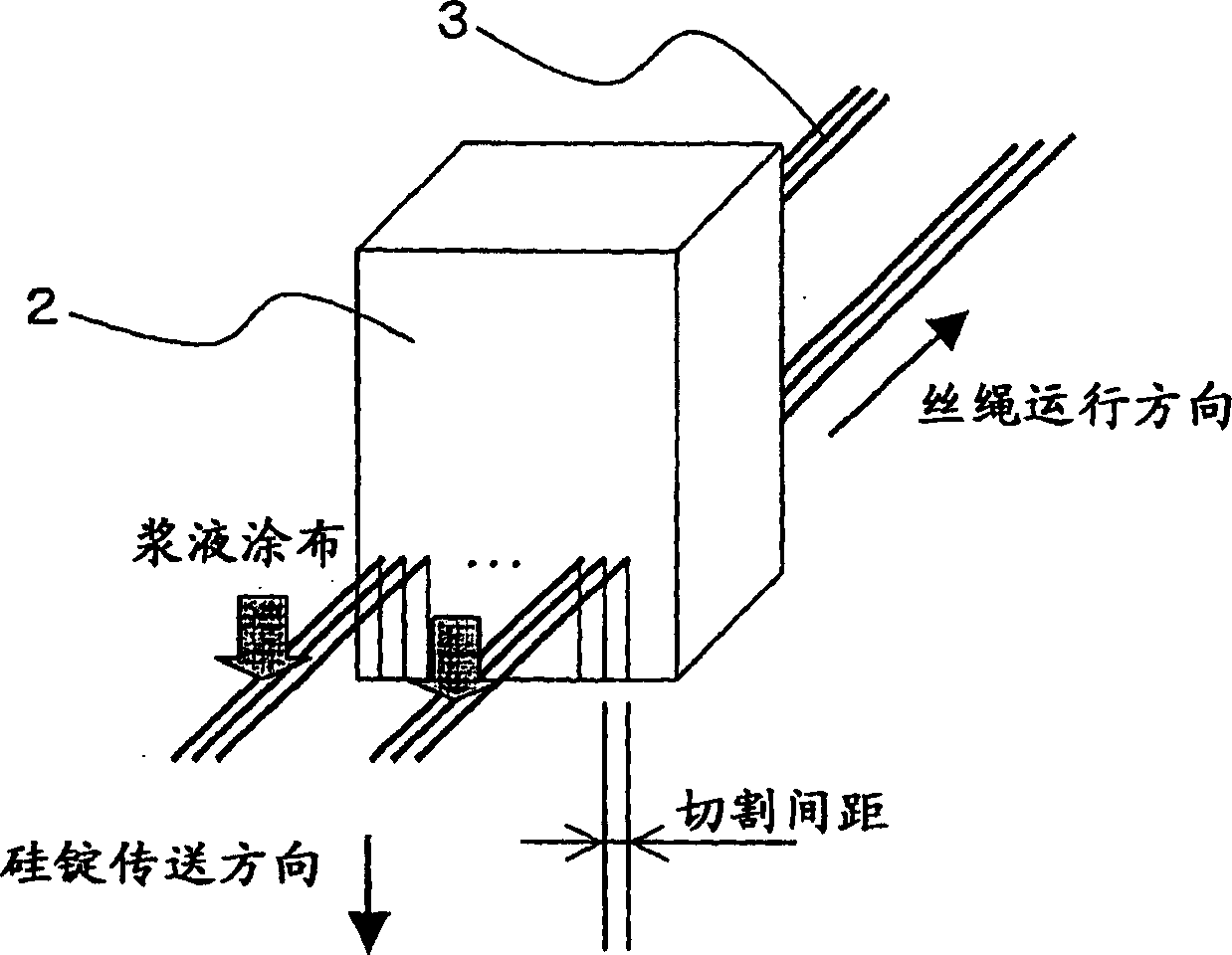

[0115] Using the obtained slurry for silicon ingot cutting, use it under the cutting conditions shown below figure 2 The composite wire saw used to cut polycrystalline silicon ingots (150mm on each side and 25mm long), and use an eddy current displacement sensor to measure the bending amount of the wire rope during processing.

[0116] Cutting condition

[0117] Wire rope diameter: 100μm (made by JFE Steel, type SRH)

[0118] Wire rope spacing: 0.39mm

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com