Pretreatment method of crop straw and device thereof

A technology for pretreatment of crop straws, applied in the method and its device, and the field of pretreatment of crop straws, can solve problems such as operating efficiency and working time extension of guillotine cutting devices, affecting the overall efficiency of operations, and unstable machine work, etc. Safety, improved cutting efficiency, continuous and reliable feeding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Such as figure 1 As shown, a method for pretreatment of crop stalks, comprising the following steps:

[0037] A. Use the crop straw cutting device to cut the crop straw to be treated, and cut it into small sections with a length of 10-19 cm for later use;

[0038] B. Carry out infiltration treatment on the crop stalks cut in step A, that is, put the small crop stalks with a length of 10-19 cm into the water tank 7, add water in the water tank 7 at a ratio of 1:1, and soak for 24 hours ;

[0039] C, put the crop stalks after soaking treatment in step B into the steam explosion tank 8, feed saturated hot steam into the steam explosion tank 8, boost the pressure to 0.6 MPa, 1.0 MPa and 1.5 MPa respectively, and the pressure holding time is 3 After 3 minutes, the steam-exploded straw can be obtained by releasing the pressure; add water at 60°C to the steam-exploded straw with a solid-to-liquid ratio of 1:10 to remove the soluble matter on the surface of the steam-exploded...

Embodiment 2

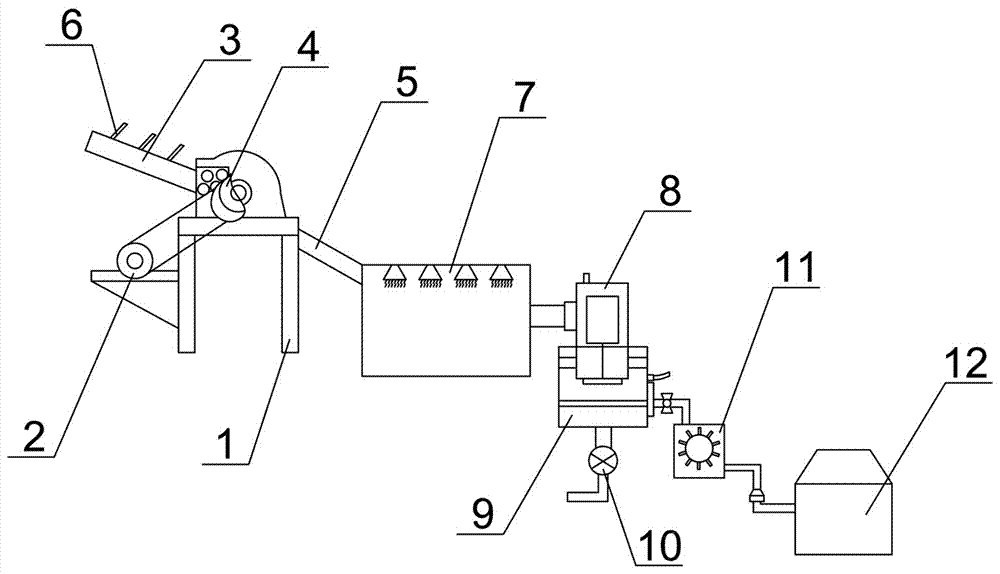

[0043] Such as Figure 1 to Figure 5 As shown, a device for pretreating crop stalks includes a crop stalk cutting device, a water tank 7, a steam explosion tank 8, an air drying chamber 9, a pulverizer 11 and a storage tank 12;

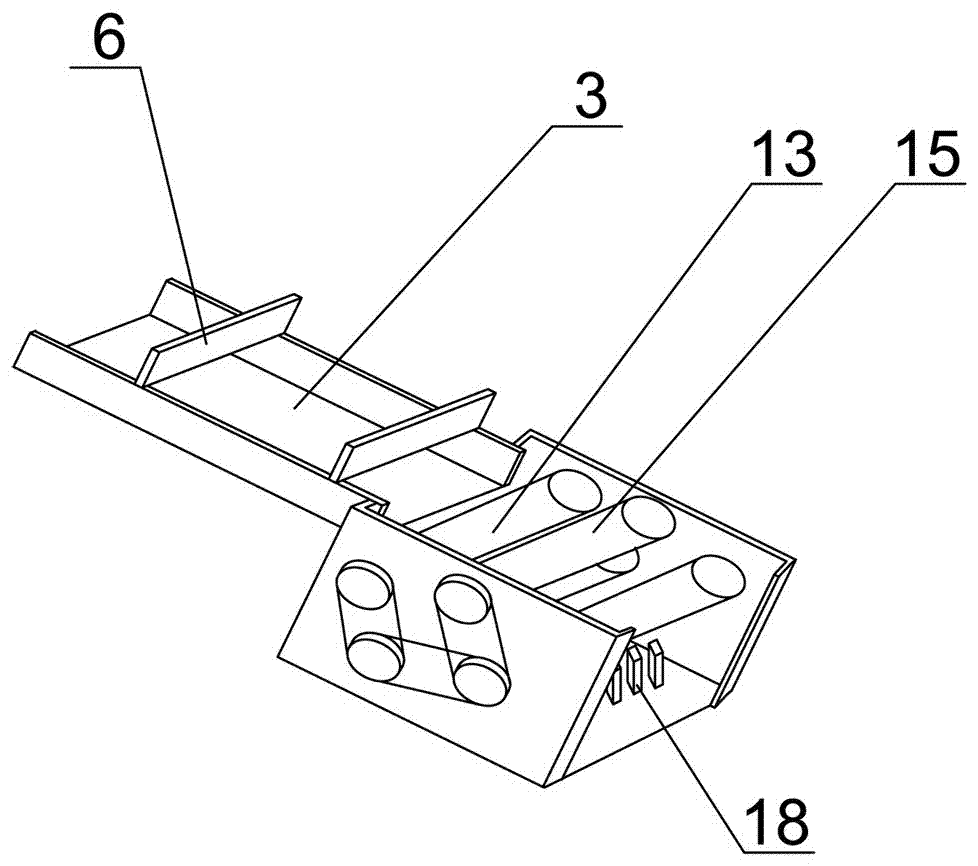

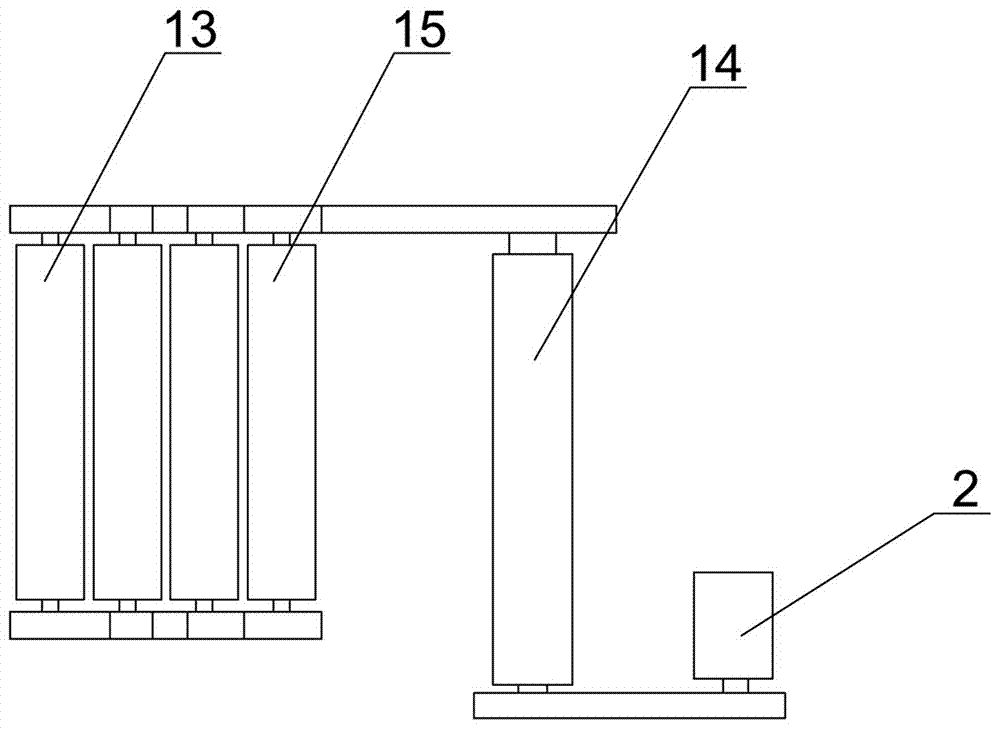

[0044] The crop straw cutting device is used for cutting the crop straws to be treated; the crop straw cutting device includes a frame 1, a transmission system for the operation of the crop straw cutting device, a feeding room and a cutting device ; The feeding chamber is located on the left side of the frame 1, and the feeding chamber includes a feeding hopper 3, a compacting plate 6 and a group of feeding rollers, and the feeding hopper 3 is in a "U" shape, and the feeding hopper The upper plane of 3 is provided with two or more compacting plates 6 in a transverse direction, the inner angle between the rear end surface of the compacting plates 6 and the upper plane of the feed hopper 3 is less than 90°, and the feeding roller shaft is located at the...

Embodiment 3

[0047] Such as Figure 1 to Figure 5 As shown, a method and device for pretreatment of crop stalks, a method for pretreatment of crop stalks:

[0048] A. Use the crop straw cutting device to cut the crop straw to be treated, and cut it into small sections with a length of 10-19 cm for later use;

[0049] B. Carry out infiltration treatment on the crop stalks cut in step A, that is, put the small crop stalks with a length of 10-19 cm into the water tank 7, add water in the water tank 7 at a ratio of 1:1, and soak for 24 hours ;

[0050] C, put the crop stalks after soaking treatment in step B into the steam explosion tank 8, feed saturated hot steam into the steam explosion tank 8, boost the pressure to 0.6 MPa, 1.0 MPa and 1.5 MPa respectively, and the pressure holding time is 3 After 3 minutes, the steam-exploded straw can be obtained by releasing the pressure; add water at 60°C to the steam-exploded straw with a solid-to-liquid ratio of 1:10 to remove the soluble matter on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com