Circular saw blade

A circular saw blade and saw blade technology, which is applied in metal sawing equipment, sawing machine tools, metal processing equipment, etc. The effect of small size, increased ventilation, and rapid heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is described below in conjunction with accompanying drawing.

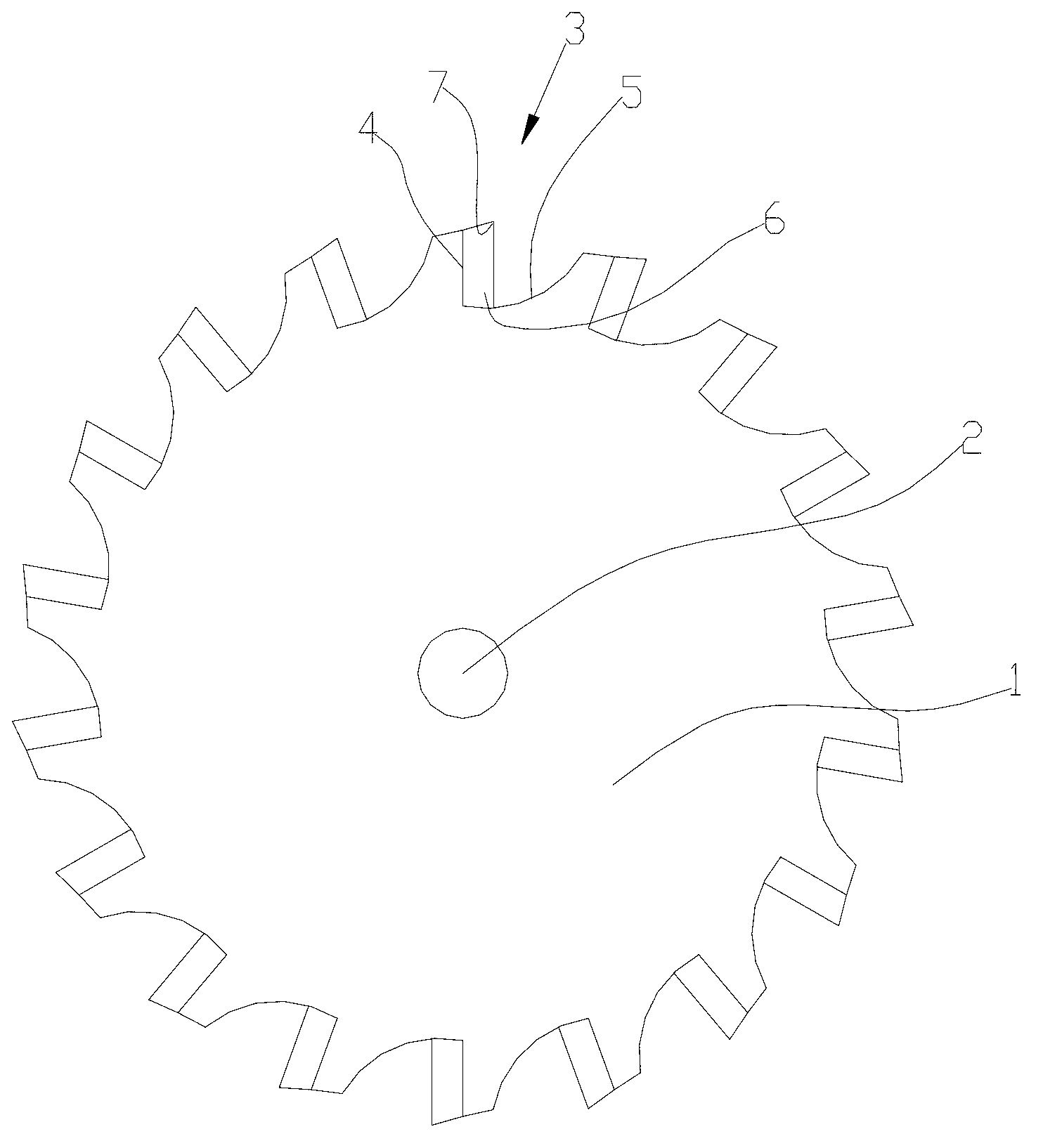

[0013] attached figure 1 It is a kind of circular saw blade according to the present invention, which includes a saw blade base body 1, a central hole 2 is opened in the center of the saw blade base body 1; a plurality of tooth grooves 3 are uniformly arranged on the saw blade base body 1 along the periphery, The tooth groove 3 is a groove formed by connecting a right-angled side 4 and a concave arc-shaped side 5; the right-angled side 4 is equipped with a sawtooth 6; the thickness of the sawtooth 6 is greater than the thickness of the saw blade base 1, and the sawtooth cutting edge The sharp angle ensures that the saw teeth 6 are not deformed during the cutting process, and the slices are smooth, thereby improving the cutting quality. The sawtooth 6 is detachably installed on the right-angled side 4. When the sawtooth 6 or the saw blade base 1 is damaged, it can be replaced at any tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com